12CI400A • 12HI400A

17

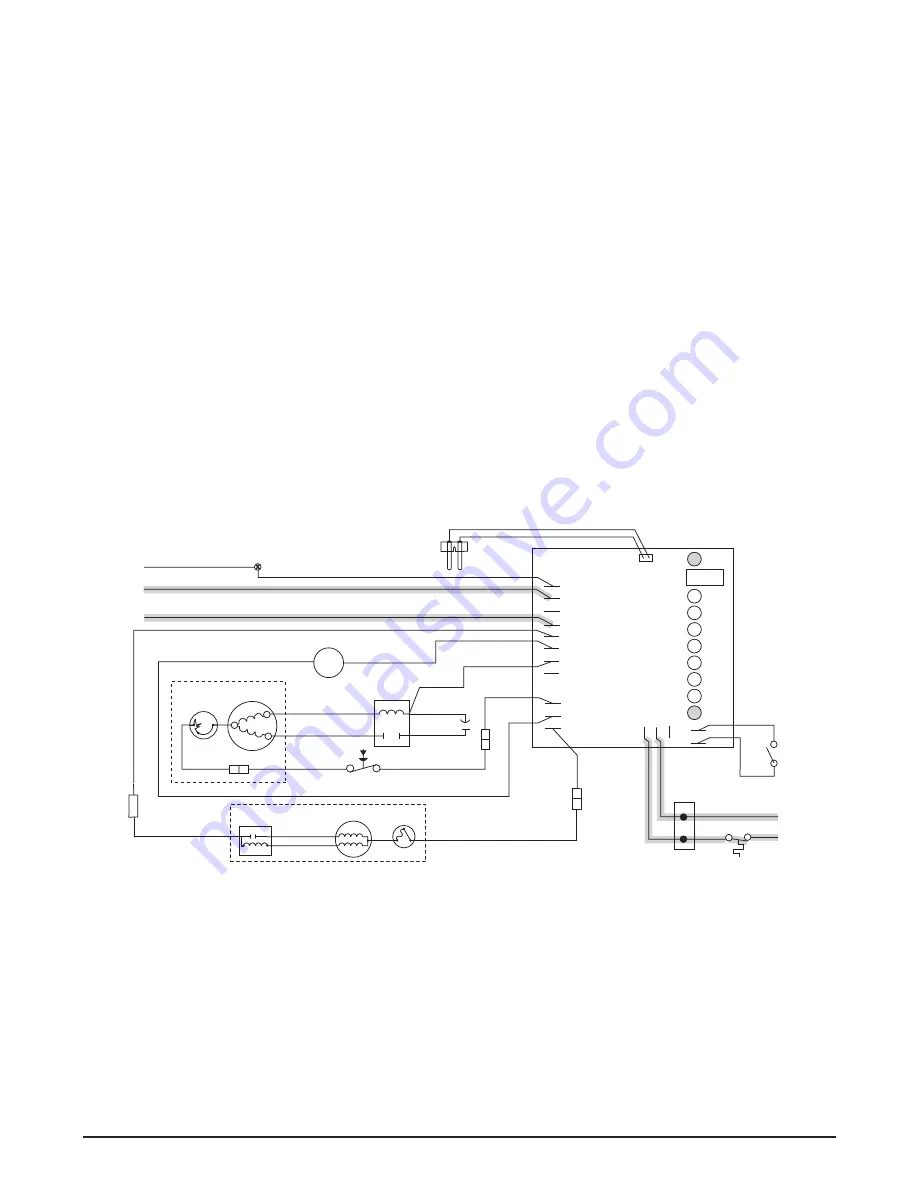

Ice machine operational and diagnostic sequences

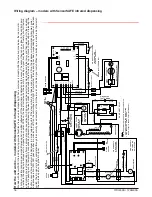

The wiring diagrams that follow illustrate the circuitry of Follett ice machines used with 12 series ice dispensers.

Both normal operation (stages 1 - 6) and non-normal diagnostic sequences showing torque-out (stages 7 - 10)

for use in troubleshooting are shown.

Circuitry notes

§

Compressor switch should read open in ON position.

§

Compressor start relay is position sensitive. See label on start relay for proper orientation.

§

Bin signal is 115 V, 60 Hz.

§

Flashing water LED at any time indicates that water signal to board has been lost for more than one second.

§

Ten-second delay: There is a 10 second delay in reaction to loss of water (WTR) or bin (B-E) signals. If signals

are not lost for more than 10 seconds, no reaction will occur.

GRD

L1

L1

L2

L2

L2

L2

L2

COMPRESSOR

FAN

DRIVE

DR

C

20M

60M

2ND

WTR

B-T

B-E

RESET

GRD

G

B

W

FAN

BLACK

WHITE

BLACK

BLACK

R

ORANGE

S

S

L

COMPRESSOR

C

RED

BLACK

BLACK

WHITE

INPUT

POWER

WATER

SENSOR

CONTROL

BOARD

BLA

CK

24V

COMMON

LINE

V

A

C

RED

RED

WHI

TE

BLA

CK

BIN T-STAT

BIN SIGNAL

FROM DISPENSER

JUNCTION BOX

(MCD400A/WVS series –

blk wire is on 24V)

WHITE

RED

WHITE

M

1

COMPRESSOR

SWITCH

PWR

BLACK

T.O.L.

BLACK

RED

HIGH PRESSURE

SAFETY SWITCH

M

BLUE

RELAY

START

T.O.L.

BLACK

4

2

3

YELLOW

GEAR MOTOR

START

RUN

WHI

TE

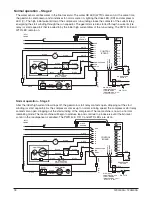

Normal operation – Stage 1

Power is supplied to L1 of the control board. The ice level control in the dispenser is closed and calling for ice,

supplying signal voltage to the control board. The control board will now go through the start-up sequence.

Less than 30 seconds will elapse as the water sensor located in the float reservoir checks for water in the

reservoir. The bin empty LED (B-E) and power LED (PWR) will be on.