Cleaning tool checklist

§

(1 or 2) 1.5 gallon (or larger) plastic bucket

§

(2) clean cloths

§

Sanitary gloves

§

Safety glasses

§

(2) SaniSponge™ (P/N 00131524 - single sponge)

§

SafeCLEAN Plus ice machine cleaner

SafeCLEAN Plus Solution: Follow the directions on the SafeCLEAN Plus packaging to mix 1 gal. (3.8 L) of

Follett SafeCLEAN Plus solution. Use 100 F (38 C) water.

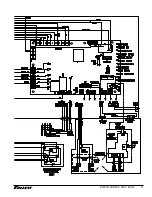

Ice Machine and Dispenser

Cleaning procedure

Note: Check drains and drain cup to ensure they are open and flowing freely.

1. If ice machine was running recently, ensure that the evaporator is completely free of ice before

proceeding. If there is ice in the evaporator, complete steps 2-7 using only hot water to remove the ice

then begin Cleaning Procedure again.

2. Remove front cover and turn OFF bin signal switch.

3. Dispense all ice from storage hopper and discard.

4. Remove top of machine and hopper lid.

5. Press CLEAN switch. The MAINTENANCE light will turn on and the machine will drain. Wait for the LOW

WATER light to turn on.

6. Remove lid from cleaning cup and fill (about 1 quart) until SafeCLEAN Plus solution overflows from the

ice transport tube into the hopper. Place lid back on cup. Save remainder of SafeCLEAN Plus solution.

7. CLEANER FULL light will turn on and machine will start cleaning cycle then rinse three times; this

process takes approximately 15 minutes.

8. While ice machine is cleaning, clean dispenser as follows:

a. Remove center thumbscrew, locking plate, two wingnuts and backing plate from front of storage hopper.

b. Remove stud assembly, baffle, wheel, and any remaining ice.

c. Remove dispense chutes from splash panel.

d. Submerse drain grille in SafeCLEAN Plus solution and allow to soak to remove any scale buildup.

e. Wipe inside of hopper lid, stud assembly, baffle, wheel, inside of storage area, dispense chutes, drain grille

and drain pan with damp cloth wrung out in SafeCLEAN Plus solution. Thoroughly rinse all parts with damp

cloth wrung out with clean water.

Note: To avoid possible damage to motor assembly, only use a damp cloth to clean storage hopper. Do not

allow water to run through motor shaft hole in bottom of hopper.

9. When machine is finished cleaning, the MAINTENANCE light will turn off.

10. Reinstall dispense chutes, wheel, baffle, stud assembly and knurled nuts.

11. Remove top bearing insulation. Loosen Phillips-head screw on nozzle connected to evaporator. Remove

nozzle from evaporator side only, leave other side of nozzle connected to transport tube.

12. Soak one SaniSponge in remaining SafeCLEAN Plus solution.

13. Insert the sponge soaked in SafeCLEAN Plus solution into nozzle then insert a dry sponge into the

nozzle.

14. Replace nozzle onto evaporator and tighten screw. Ensure drain is connected to reservoir and vent tubes

are connected to evaporator drain pan. Replace top bearing insulation.

15. Turn ON bin signal switch. Wait for ice to push sponges through transport tube.

16. Collect sponges from ice storage bin.

17. Replace hopper lid, machine top, and install front cover.

18. After 10 minutes, dispense all ice and discard.

User Interface and Exterior Cabinet

§

Clean stainless steel panels with stainless steel cleaner.

8

E12CI414A R290, 230 V 50 Hz