87

0

20

40

60

80

100

120

140

160

180

200

220

240

260

0

3.000

6.000

9.000

12.000

15.000

18.000

21.000

24.000

27.000

30.000

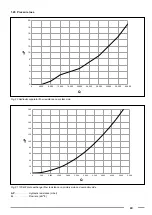

∆

P

Q

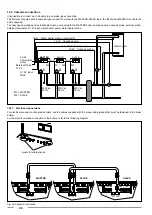

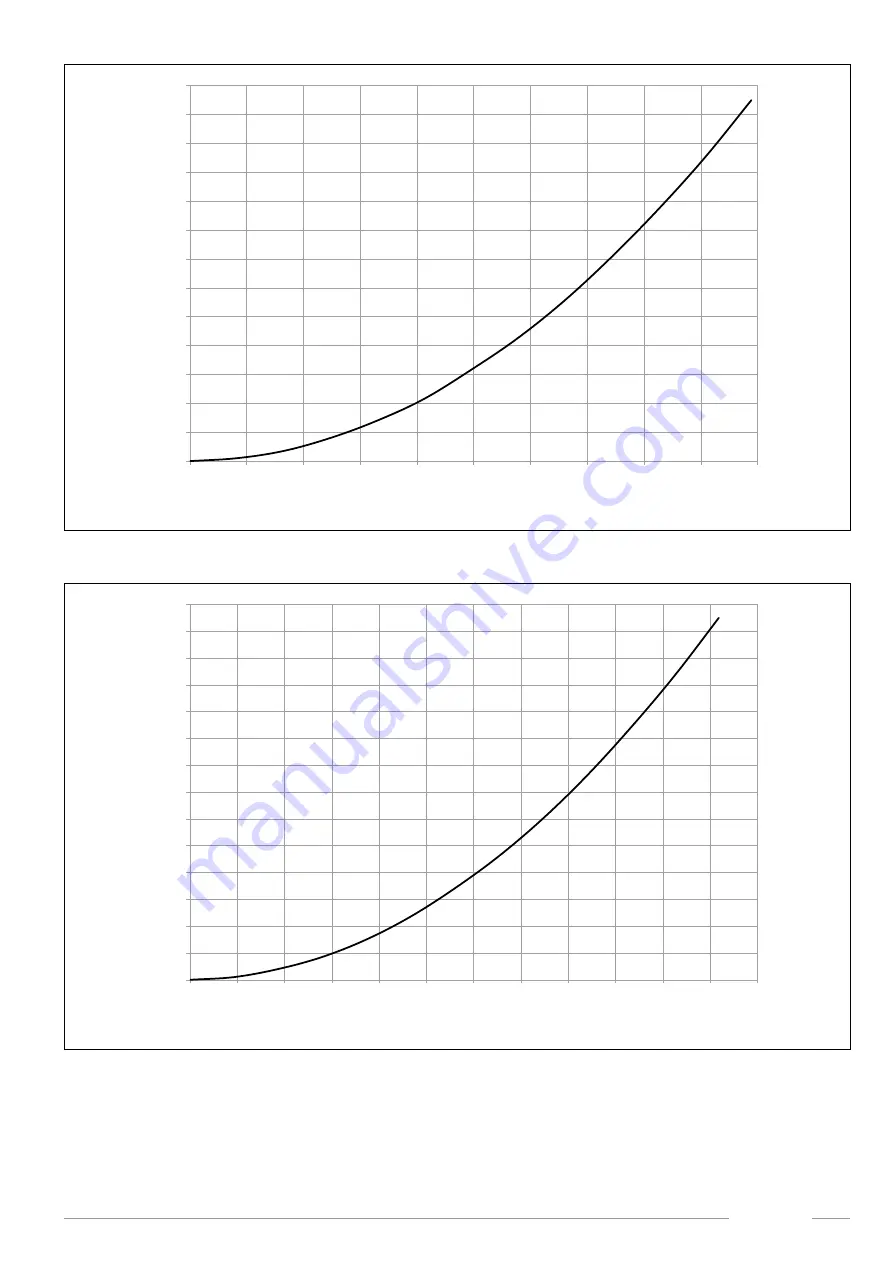

Fig. 28 690 kW plate exchanger flow resistance on primary side and secondary side

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

0

3.000

6.000

9.000

12.000

15.000

18.000

21.000

24.000

27.000

30.000

33.000

36.000

∆

P

Q

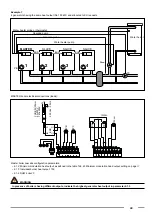

Fig. 29 780 kW plate exchanger flow resistance on primary side and secondary side

ΔP

. . . . . . . . . . . Hydraulic resistance (mbar)

Q

. . . . . . . . . . . . Flow rate (dm

3

/h)