M-6007-Z460FFT(FRT)

Crate Engine

GUIDE

NO PART OF THIS DOCUMENT MAY BE REPRODUCED WITHOUT PRIOR AGREEMENT AND WRITTEN PERMISSION OF

FORD PERFORMANCE PARTS.

Techline 1-800-367-3788

Page 16 of 24

IS-1850-0636

Factory Ford shop manuals are available from Helm Publications, 1-800-782-4356

OIL CAPACITY

7 quarts total for M-6007-Z460FRT and 9 quarts total for M-6007-Z460FFT, with M-6731-FL1A oil filter or equivalent. Any

external coolers or remote filter assemblies will require incremental oil.

VALVE COVERS

The M-6007-Z460FFT(FRT) comes with 302-135 valve covers. Make sure the valve covers are correct for your PCV

system.

IGNITION SYSTEM CONSIDERATIONS/COMMON PROBLEMS

The ignition system must deliver a properly timed, high voltage spark. Many factors determine spark timing. The

most common factors include compression ratio, fuel quality, fuel octane rating, combustion chamber design,

engine operating temperature, inlet air temperature, altitude, and load.

Avoid too much or too little timing for your engine combination.

Avoid hooking up the vacuum advance to intake manifold vacuum instead of ported vacuum.

Avoid inductive crossfire created by improper plug wire routing. When routing plug wires keep them separated.

Improper timing can damage pistons, rod bearings, head gaskets, and many other engine parts.

Typical total mechanical advance timing at 4000 rpm for Ford Performance crate engines:

M-6007-Z460FFT(FRT) is 30° BTDC (91 octane R+M/2 minimum fuel requirement.).

DISTRIBUTOR GEAR INSTALLATION INSTRUCTIONS:

The M-6007-Z460FFT(FRT) comes with a billet steel hydraulic roller camshaft. Distributor with steel gear required.

STEP 1:

Remove roll pin from distributor gear and shaft. Save pin for re-assembly.

STEP 2:

Verify that the shaft endplay is .024" to .035". Modify collar if necessary. Some aftermarket distributors

may be constructed in a manner that does not allow you to achieve .024" to .035" of endplay. See

“Alternative method of verifying correct distributor gear installation” if your distributor does not have .024"

to .035" endplay.

STEP 3:

Press original distributor gear off shaft.

STEP 4:

Mark location of original roll pinhole on the shaft by drawing a vertical line along the shaft that intersects

the hole. Measure from the centerline of the roll pinhole to a fixed point above it. Note that dimension.

STEP 5:

Press new distributor gear onto shaft.

NOTE:

Replacement distributor gear does not have roll pinhole.

STEP 6:

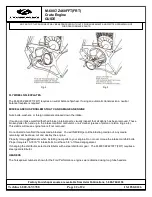

Pull distributor shaft out of distributor housing to eliminate endplay (see Fig. 1).

STEP 7:

Check location of distributor gear on distributor shaft (see Fig. 1). If it is not in the correct location, use a

press to move the gear to the correct location.