FAT-0113

EN

Copyright © 2015

P a g e

|

7

www.Ford-tools.com

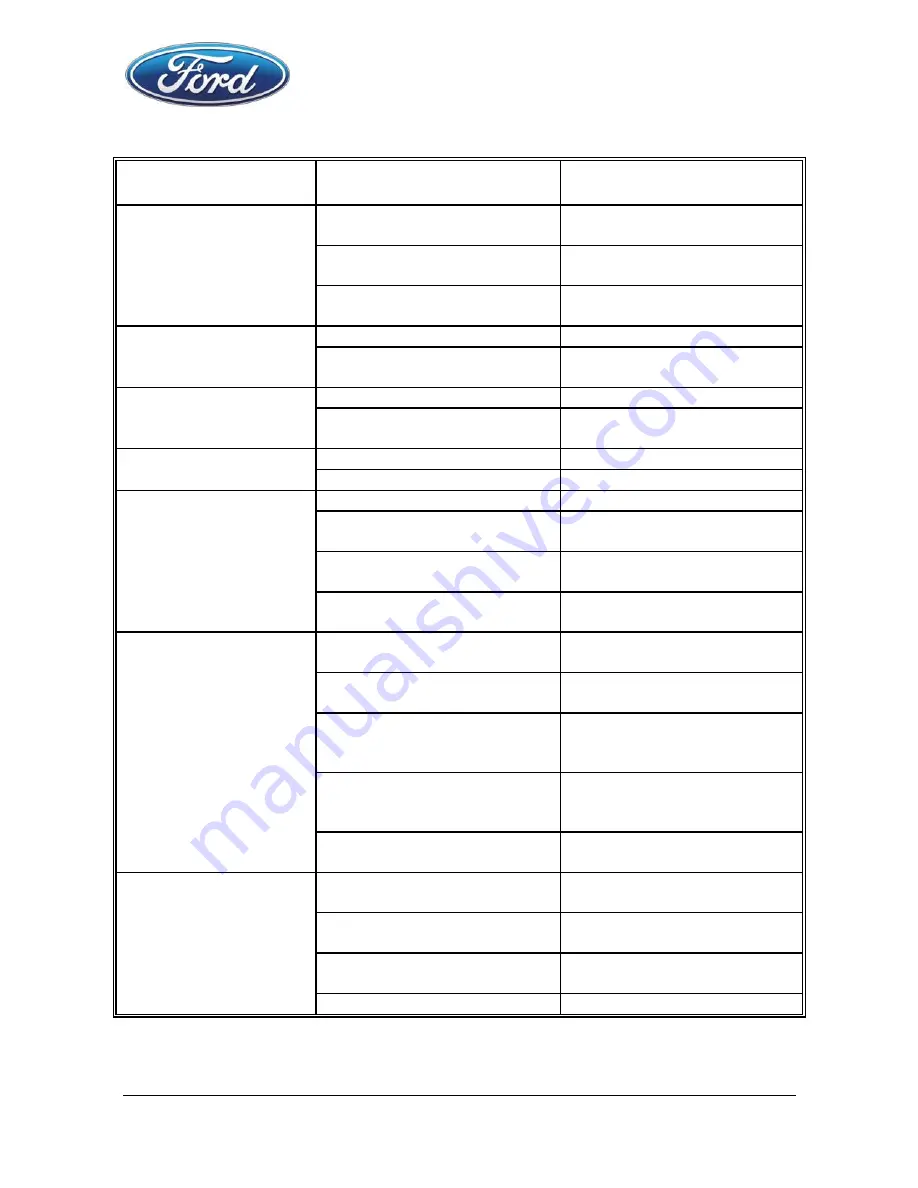

SYMPTOM

PROBLEM

SOLUTIONS

Air leak near top of

tool or in trigger area

O-ring in trigger valve is

damaged.

Check and replace O-ring.

Trigger valve head are

damage.

Check and replace.

Trigger valve stem, seal or

O-ring are damaged.

Check and replace trigger

valve stem, seal or O-ring

Air leak near bottom

of tool.

Loose screws.

Tighten screws.

Worn or damaged O-rings

or bumper.

Check and replace O-rings

or bumper.

Air leak between body

and cylinder cap.

Loose screws.

Tighten screw.

Worn or damaged O-rings

or seals.

Check and replace O-rings

or bumper.

Blade driving fastener

too deep.

Worn bumper.

Replace bumper.

Air pressure is too high.

Adjust the air pressure.

Tool does not operate

well: can not drive

fastener or operate

sluggishly.

Inadequate air supply.

Verify adequate air supply.

Inadequate lubrication.

Place 2 or 6 drops of oil

into air inlet.

Worn or damaged O-rings

or seals.

Check and replace O-rings

or seal.

Exhaust port in cylinder

head is blocked.

Replace damaged internal

parts.

Tool skips fasteners.

Worn bumper or damaged

spring.

Replace bumper or pusher

spring.

Dirt in front plate.

Clean drive channel on

front plate.

Dirt or damage prevents

fasteners from moving

freely in magazine.

Magazine needs to be

cleaned.

Worn or dry O-ring on

piston or lack of

Lubrication.

O-ring needs to be

replaced and lubricate.

Cylinder covers seal

leaking.

Replace Sealing washer.

Tool jams.

Incorrect or damaged

fasteners.

Change and use correct

fastener.

Damaged or worn driver

guide.

Check and replace the

driver.

Magazine or nose screw

loose.

Tighten the magazine.

Magazine is dirty.

Clean the magazine.