A-JCA-2 chuck arbor, A-WM6 wheel mandrel

and S.B0 Flexades

®

are right hand side

accessories, intended for use on the right

hand side of the lathe as you face it. Do not

use them on the left side as buff, wheel or

tool may unscrew under load. The supplied

A-TM5 tapered spindle and optional A-WM-5

wheel mandrel is intended for use on the left

side only. (Every spindle and mandrel is

marked with an R or L to indicate right or

left hand.)

Attach the spindles or mandrels by sliding

them onto the motor shaft until there is only

a 1/8

″

space between the motor housing and

inside edge of the spindle or mandrel. Be

sure that the two set screws line up over the

flat on the motor shaft. Tighten both screws

securely with supplied hex key.

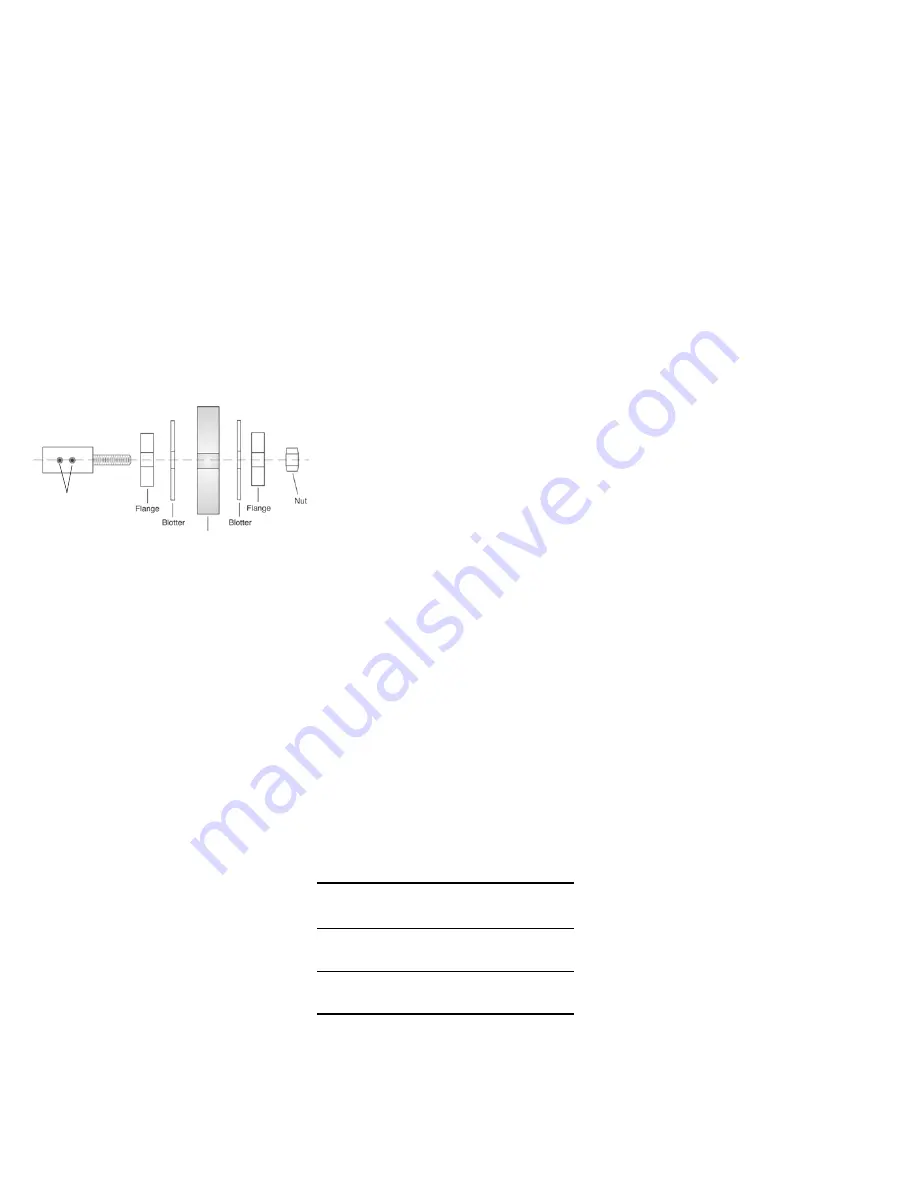

See Figure 2 for mounting rubber wheels or

other accessories with 1/4

″

diameter center

holes on A-WM-6 wheel mandrel. Run the

lathe at slow speed without a buff (or wheel)

to see that the spindles, mandrel, or collet

holder on the lathe are running true.

Never use a buff, brush, abrasive wheel,

or any other accessory that is rated under

7,000 RPM. Never use one that appears to

wobble or vibrate. It could damage the lathe

or injure you.

Never use buffs over 4

″

in diameter.

Never use grinding wheels over 2

″

in

diameter. Never use rubber bonded wheels

over 3

″

in diameter.

Please refer to Figure 2 for the proper mount-

ing procedure for wheels or brushes on the

A-WM-6 or A-WM-5 mandrel.

Tapered Spindles: For use with 3

″

or smaller

wheels with arbor holes up to 7/16

″

cotton,

felt, and chamois buffs with shellac hardened

leather or lead centers. Also for felt inside

ring buffs mounted on wooden mandrels,

EXL Wheels, Radial Bristle Discs with A-4561

or A-4562 tapered spindle adapters.

Mounting Wheels onto Tapered Spindles:

Turn lathe on and run at low speed. Align arbor

hole of accessory with screw-like threads of

tapered spindle. The accessory will self tighten

as it travels up the spindle threads. To remove,

turn lathe off and manually unscrew your

wheel or buff.

Collet Holder: Loosen the two hex or allen

screws on A-CHA-5 Collet Holder and slide

onto exposed motor shaft of BL Lathe. Position

screws over the flat area of the shaft

and re-tighten.

Changing Collets and Accessories: A-CHA-5

Collet Holder comes with 3/32

″

, 1/8

″

and 1/4

″

collets for use with accessories and mandrels

with 3/32

″

, 1/8

″

and 1/4

″

diameter shanks. The

1/4

″

collet typically comes installed. To switch

out a collet and/or an accessory with a differ-

ent shank size, insert supplied pin with safety

spring into hole next to the two set screws.

Insert the wrench onto the flats at the tip of the

chuck nut and unscrew nut while holding pin

in place to keep spindle from turning. Remove

chuck nut and switch out collet. This may

require the use of a needle nose pliers. Replace

chuck nut and tighten after installing the

desired accessory or mandrel. Never tighten a

chuck nut without an accessory installed, as

damage to the collet may occur.

Chuck Arbor: Loosen the two hex or allen

screws on A-JCA-2 Chuck Arbor and slide onto

exposed motor shaft of BL Lathe. Position

screws over the flat area of the shaft

and re-tighten.

Changing Accessories: A-JCA-2 has a geared

3-jaw #0 chuck. Open chuck jaws as far as

necessary with key provided. Insert shank of

accessory fully into the chuck. Tighten each of

the jaws with chuck key until accessory is

secure and centered. If accessory does not

run true, reopen jaws, rotate accessory and

retighten. To release accessory, simply reopen

chuck jaws with key and pull out accessory.

The chart above shows the SFPM obtained with

different diameter wheels at various speeds.

Operation

Because of the higher maximum speed

(approxi-

mately 7,000 RPM) and variable speed control,

the Foredom Bench Lathe has several advan-

tages over conventional single or two speed

polishing and buffing lathes:

1.

The same size buffing wheel can be used to

obtain different surface speeds, as measured

in surface feet per minute (SFPM). 3

″

or 4

″

diameter buffs can provide the 1,750 to 3,450

SFPM recommended for polishing and the

3,450 and higher SFPM recommended for

buffing. The chart below shows the SFPM

obtained with different diameter buffs at vari-

ous speeds.

2.

The SFPM can be varied while using the

same diameter buff or wheel. This will give

better results on different types of material.

3.

The 7,000 RPM maximum speed will enable

you to get much higher SFPM with smaller 1

″

or 2

″

buffs or inside ring buffs, than slower

single or double speed equipment.

4.

3M Scotch-Brite™ Radial Bristle Discs in 2

″

and 3

″

diameters require 5,000 or higher RPM

or optimum performance, making them perfect

for use in the lathe.

5.

The maximum speed of 7,000 RPM is also

fast enough to permit the use of small mount-

ed abrasive points, brushes, cutters, or other

accessories in the A-CHA-5 collet holder,

S.B0-516 Flexade

®

or A-JCA-2 chuck holder.

For additional information on buffing and

polishing procedure, wheel selection, and

Foredom buffing and polishing compounds,

please refer to the Foredom Buffing and

Polishing Guide (Form No. 1234).

Maintenance

Lubrication: The Foredom Bench Lathe has

prelubricated ball bearings, a dust-proof motor

housing and does not require any lubrication.

The motor is designed to operate above room

temperature which will be warm to the touch but

not harmful to the motor.

Motor Brush Wear: Disconnect power cord

before checking for motor brush wear. Check for

motor brush wear periodically (about every 200

hours of continuous operation). Unscrew the

motor brush tube caps (located on front and

back of right side of lathe), check the motor

brush length, and install new brushes if the old

ones are less then 3/16

″

(4.7mm) in overall

length. Be sure that the radius in the end of the

brush is in line and conforms to the commutator

surface. Replacement motor brushes (MP262P)

are available from your dealer, the factory, or you

may order them from www.foredom.net.

Buff

Speed

SFPM

Diameter

1

″

Full 7,000 RPM

1,750

Med 4,000 RPM

1,000

2

″

Full 7,000 RPM

3,500

Med 4,000 RPM

2,000

3

″

Full 7,000 RPM

5,250

Med 4,000 RPM

3,000

4

″

Full 7,000 RPM

7,000

Med 4,000 RPM

4,000

Motor Shaft

set screws

Rubber

Wheel

Figure 2

Wheel Mandrel A-WM-5 and A-WM-6

Assemble all components in proper sequence.

(A-WM-5 left side wheel mandrel has same

components in opposite sequence)