10

CARE AND MAINTENANCE

To enjoy the outstanding performance from your fire pit, make sure you perform the following activities on a

regular basis:

1. Use warm soapy water for cleaning. Never use flammable or corrosive cleaning agents.

2. While cleaning the fire pit, make sure to keep the area around the burner dry at all times. DO NOT submerge

the control valve assembly. If the gas control is submerge in water, DO NOT use it. It must be replaced.

3. Air flow must be unobstructed. Keep controls, burner, and circulating air passageways clean. Signs of

possible blockage include:

(1). Gas odor with extreme yellow tipping of flame.

(2). Fire pit does NOT reach the desired temperature.

(3). Fire pit flame is excessively uneven.

(4). Fire pit makes popping noises.

(5). Spiders and insects can nest in burner or orifice. This dangerous condition can damage fire pit and

render it unsage for use. Clean burner holes by using a heavy-duty pipe clearer. Compressed air may

help clear away small particles.

4. Carbon deposits may create a fire hazard. Clean burner with warm soapy water if any carbon deposits

develop.

NOTE:

Always allow fire pit to cool COMPLETELY before attempting service or maintenance.

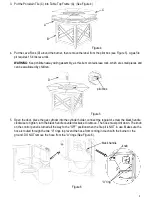

Observe Flame Height When Lit:

Flame should be a blue / yellow color between 1~2 in. height (see Figure 20).

Good

Bad

Figure 20