2) Remove the clutch cover.

(Figure 3)

3) Slide the guide bar on the bar

bolts until the guide bar rests against

the clutch drum sprocket. (Figure 4)

4) Hold the chain with the drive links

as shown. The drive links should be

facing inward with the cutters facing

to the right, or direction of rotation.

(Figure 5)

5) Fit the drive links in the clutch

drum sprocket. (Figure 6)

Figure 6

6) Place the chain drive links into the

bar groove.

7) Pull the guide bar forward to

make sure all of the drive links are in

the bar groove.

8) Reinstall the clutch cover. (Figure

3) Make sure the adjusting pin is

aligned with the hole in the guide

bar.

CAUTION: Make sure the

adjustment pin aligns with the hole.

Failure to align the pin and install the

cover properly may result in

damage, possibly permanent, to

your saw.

ADJUSTING CHAIN TENSION

Before adjusting, make sure the bar

knobs are loosened 1 ½ - 2 turns.

Adjusting the chain tension with the

knobs tight can cause damage.

Checking the Chain Tension

Check the chain tension by using a

screwdriver to move the chain along

the bar. If it does not rotate, it is too

tight. If it sags below the bar, it is too

loose.

Adjusting the Chain Tension

The chain stretches slightly during

each use, especially the first few

times the saw is used. Always check

the chain tension each time the saw

is used and refueled.

1) Make sure the bar knobs are

loosened 1-1/2 – 2 turns.

2) Using a screwdriver, adjust the

tension of the chain. The adjusting

pin is located right below the two bar

knobs.

4

3) Turn the screw to the right to

increase the tension and turn it to

the left to release tension.

4) Using a screwdriver, move the

chain around on the guide bar to

make sure all of the links are in the

bar groove. If the chain does not

rotate, it is too tight and the

adjuster needs to be loosened.

5) Tighten the bar knob securely

after the tension is adjusted.

FUELING AND LUBRICATION

Use regular grade unleaded

gasoline mixed with 40:1 2-cycle

engine oil. Do not use a fuel

mixture that has been stored for

more than 90 days.

The bar and chain require constant

lubrication in order to function

properly. Lubrication is provided by

the oiler system. Lack of oil will

cause damage to the bar and

chain. Smoke coming from the

chain and discoloration on the bar

are signs the oil is low.

Fueling Safety Instructions

1) Do not smoke while fueling or

operating the saw.

2) Do not allow sparks or flame in

the area where the fuel is poured or

mixed. Always allow the engine to

cool before refueling.

3) When refueling, turn the engine

off and let it fuel in a non-

combustible area. Slowly remove

the fuel cap and refuel the saw.

4) Mix and pour the fuel in a well-

ventilated outdoor area. Store the

fuel in a cool, dry place. Wipe up

fuel spills before attempting to start

the saw.

5) Start the engine at least 10 feet

from the fueling site

Figure 3

Figure 4

Figure 5

Figure 7

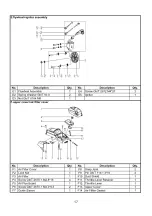

Summary of Contents for 20120

Page 13: ...13 Parts List...

Page 14: ...14...

Page 15: ...15...

Page 16: ...16...

Page 17: ...17...

Page 18: ...18...

Page 19: ...19...