4.Basic operation of the machine

A: Knife holder assembly and adjustment

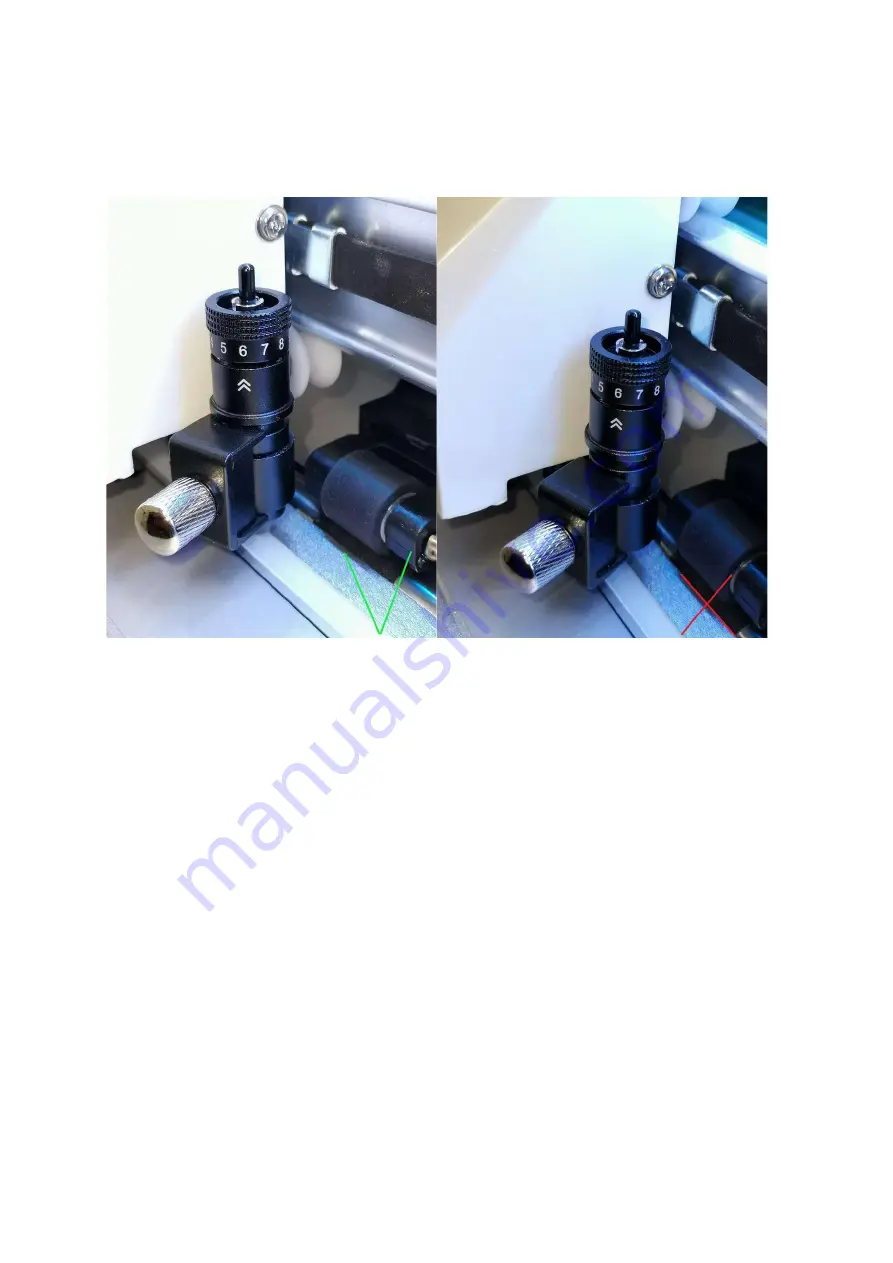

Before the first use, the correct fixing of the handle consists in its free fall onto the mounting

in the head after unscrewing the fixing screw.

To keep the handle stable, tighten the screw firmly with your fingers.

The knife holder has a total of 10 settings (in the order of 123456789AB).

The larger the number on the handle, the longer the protruding tip of the knife, which allows

for a deeper cut in the material.

The default blade position is factory set for standard transparency film, other setting items

should be changed to correct the blade position according to different materials.

Let's take standard film cutting as an example, if the sheet is completely cut, then we have to

reduce the position of the blade on the holder to a smaller number. Conversely, if the

material has not been cut, we must set a higher number. A properly cut sheet has only the

last printed layer scratched, the other 3 are completely cut.