D. Machine Plugged in, no Power:

1. Turn machine on.

2. Check wall outlet.

3. Press the circuit breaker.

4. If the display screen on the control board is not on, check the green power light on the power board. To view

the green power light, open the operator side cover and look though the air slots in view of the power board. If

that light is on, there’s a loose wire or connector not connected.

E. Power on, Machine does not Work:

1. If the green power light is not on at the power board check the circuit breaker. Then troubleshoot back to

where you have power.

2. If the display screen reads “COVER OPEN”, ensure that the operator and top covers are closed properly.

3. If the display screen reads “PAPER OUT”, load paper into hopper.

4. If the display screen reads “FAULT”, the photo eye has detected the presence of paper for more than half a

second. Remove the jammed paper, then press the counter reset button to reset the fault. If there is no paper

jam, check for proper operation of the photo eye.

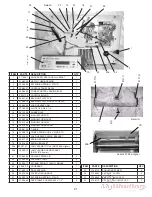

F. Photo Eye Adjustment:

There is a single photo eye, just upstream from the pressure rollers. It is used for both counting and fault

detection (doubles). There is another photo eye, at the end of the paper tray extension. This is used for

detecting 11” paper or 14” paper. There are 2 sets of lights that will allow you to adjust the sensitivity of the

photo eyes.

The first set of lights on the left is used to adjust the photo eye sensitivity, for the fault detection. There are

three lights to help you do this. The first light is red (low signal). The second light is green (good signal). The

last light is red (excess signal). These lights can be viewed by opening the operator side cover.

The second set of lights on the right is used to adjust the photo eye sensitivity, for the paper detection. There

are three lights to help you do this. The first light is red (low signal). The second light is green (good signal).

The last light is red (excess signal). These lights can be viewed by opening the operator side cover.

The photo eyes can be adjusted using the two small blue square boxes on the control board. They have screw

slots in them for delicate adjustment. The first one on the left is for fault detection and the second one to the

right is used for 14” paper detection. To adjust, place a form on top of the photo eye and change the setting on

the small blue box until the red light (excess signal) just turns to the green light (good signal).

G. Misfeeding of Forms:

1. Clean the feeder wheels.

2. Adjust the skew adjust.

3. Turn forms upside down and rotate 180 degrees and place in hopper (Z” fold forms only).

17

H. Double Feeding:

If double feeding occurs try these following steps.

1. Jog the forms to reduce static build up and to make sure the forms are not stuck together.

2. Clean the infeed wheels with a cloth dampened with a mild household cleaner.

3. Ask the technician to adjust the gate tip.

Summary of Contents for FD 2052

Page 2: ...FD 2052 AutoSeal MAINTENANCE MANUAL FOURTH EDITION 12 2006...

Page 21: ...WIRING DIAGRAM 18...

Page 37: ......

Page 38: ......