Page 13

1.

Touch screen.

One touch screen for the full process with the ability to store programs in the memory.

3.

Clamp Frame

. This holds the plastic material in position during the forming and release processes.

4.

Material Clamps

. These clamps fix the Clamp Frame firmly down. After placing the plastic under the

clamp frame the material clamps are adjusted by tightening or loosening the orange nutlets. The levers are

pulled up until they are fully over-centre. Adjustment may only be carried out while not under pressure. The

rear of the

clamp frame is completely self adjusting.

5

. Heater Box

. This carries the heating elements and is drawn forward by pulling the centrally mounted

handle.

6.

Table Lever

. When pulled towards you the table will rise to the upper limit. A further application of

pressure will lock the table in this position. During forming the table complete with mould is lifted into the

hot plastic and locked in place to ensure a good vacuum seal. At the end of the cycle the table is returned

to the lower position by pushing the handle back and away.

7.

Air pressure outlet

.

The air pressure outlet lets you power other equipment that require air pressure and

this is created by the exhaust from the vacuum pump. Do not connect compressed air to this outlet.

(508DT only)

7.

Specification Plate

. This states the model type, electrical supply needed to power the machine & other

essential data.

7.

Power connection

. You will need to use 2.5mm cable to connect it to a single phase 20amp socket

(508FS only).

See Safety section at the beginning of this manual. Note the safety labelling.

7.

Mains fuse

. This fuse protects the machine and should only be replaced by another of same type and

rating.

7.

Power Switch ON/OFF

. This is the main switch. When in the OFF position power is cut to all functions.

Before commencing any repair work always remove the mains lead from the Power Inlet Receptacle.

Electrical specifications

240V, 13 amps, 50Hz single phase

220V, 13 amps, 60Hz single phase

3.2 kW

13 amp supply

Mechanical specification

Standard material size 457 x 508mm

Max forming area 432 x 482mm

Max depth of draw 185mm

Overall width 597mm

Overall height 560mm

Overall length 700mm

Weight 100kg

1-‐

Touch screen

2-‐

Vacuum gauge

3-‐

Clamp frame

4-‐

Material clamp

5-‐

Heater box

6-‐

Table lever

7-‐

Specification plate

+ Power inlet receptacle

+ Main fuse

+ Power switch ON/OFF

+ Air output

DO NOT SUPPLY COMPRESSED AIR TO

THE AIR OUTPUT

Summary of Contents for 508DT

Page 5: ...Page 5 Initial assembly Heater shed 1 2 3 4...

Page 7: ...Page 7 508FS only Counter balance weight 1 2 3 4 5 6...

Page 8: ...Page 8 508FS only Cooling fan optional extra 1 2 3 4 5 6...

Page 9: ...Page 9 508FS only Cooling fan 7 8 9 10 11...

Page 20: ...Page 20 Operating procedures BASIC OPERATION Cont...

Page 25: ...Page 25 Service Repair How to change a heating element...

Page 26: ...Page 26 How to change a heating element...

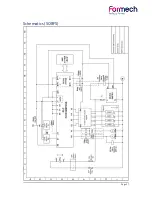

Page 27: ...Page 27 Schematics 5O8FS Schematics 5O8DT...

Page 28: ...Page 28...