STEP 4

: Reconnect Gas and Electrical Supply

Leak testing of the range shall be conducted according to the installation instructions provided with the

range.

Before operating the range after the gas conversion, always check for leaks with a soapy water solution

or other acceptable method in at gas connections installed between the gas inlet pipe of the range, gas

regulator, and the manual shut-off valve.

WARNING

DO NOT use a flame to check for gas leakage.

STEP 5

: Installation of New Rating Label

Record the model and serial number on the LP / Propane conversion label provided in this kit.

The information can be obtained from the existing Rating / Serial label. Place the LPG conversion label as

close as possible to the existing Rating / Serial label on the range.

Preparation

Before moving the range, protect any finished flooring and secure oven door(s) closed to prevent damage.

The oven door(s) can be removed to lighten the load or to fit the unit through a doorway. Only remove if

necessary. Do not remove the griddle or any other component. Door removal should only be done by a

certified installer or service technician.

Placement

Do not lift or carry the oven door by the door handle.

Use an appliance dolly to move the range near the opening. Remove and recycle packing

materials. Do not discard the anti-tip bracket supplied with the range.

Leveling

Raise the range to the desired height by adjusting the legs. The legs can be adjusted by

rotating the metal leg clockwise to raise and counter clockwise to lower.

STEP 3

: Gas Valve

a. Remove control knobs.

2

1

b. Using a flat screwdriver, adjust main burner bypass jets toward to 1/4 circle for LP until the flame

is normal.

For 9,000btu and 15,000btu burners, please refer to fig.1, which is in the center of valve

axis. For 20,000btu burners, please refer to fig.2, which is in the left side of valve axis.

fig.1

fig.2

Use soapy solutions to check for leakage on all joints.

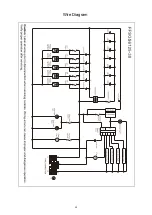

Summary of Contents for FFSGS6125-30

Page 1: ...FFSGS6125 60 FFSGS6125 48 FFSGS6125 36 FFSGS6125 30...

Page 16: ...16...

Page 17: ......

Page 30: ...Wire Diagram 30...

Page 31: ...31...

Page 32: ...32...

Page 33: ...33...

Page 34: ...2022 06...