Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk sales@fortex.co.uk +44(0)1522 718 168

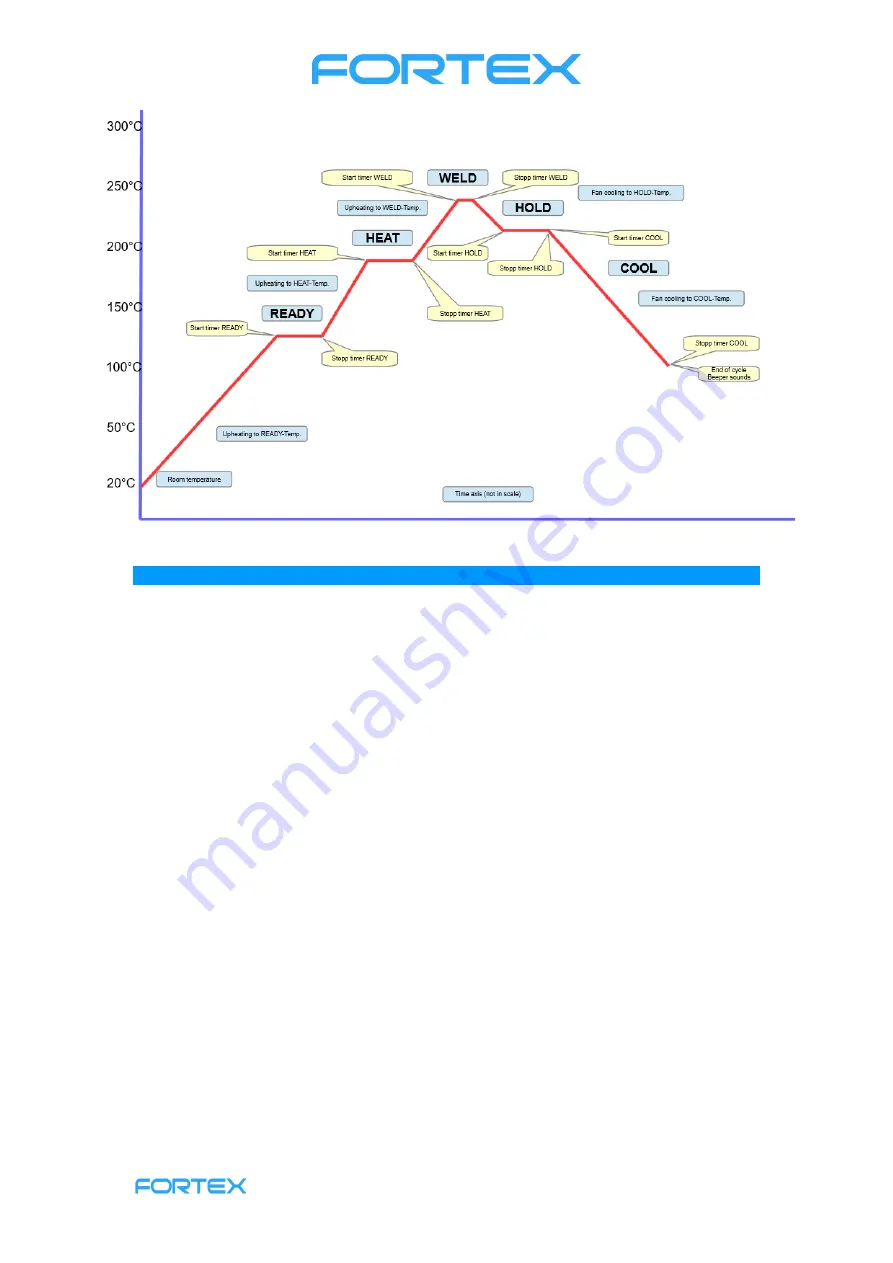

The

temperature curve

In the SMT production process, the temperature curve must be adapted to different alloy

compositions of solder paste. This temperature curve is one of the most important

parameters to ensure product quality. A standard reflow process typically has five

temperature zones. For this reason, you can define 5 temperature zones in the RF100

software to map the standard reflow process.

Each temperature plane with the appropriate temperature and time performs another

function during the soldering process. The requirement and function of each temperature

section are explained below.

Preheating (READY)

Here, the circuit board is heated from room temperature to 120-150°C to remove residual

moisture or residual gas and possibly reduce internal stress in the circuit board. It also

achieves a smooth transition to the next section. The duration is usually 1 - 5 minutes.

The specific time and temperature depends on the size of the board and the number of

components.

Heating up (HEAT)

Here, the preheated circuit board is further heated until the flux contained in the solder

paste becomes liquid. The flux removes oxides of tin paste and component.

Usually the following temperatures are set in this section:

Lead alloy solder and precious metal alloy solder (Sn 42% -Bi58% lead-free or

Sn43% -Pb43% -Bi14% lead containing low-temperature solder)

150 – 180°C

Lead-containing medium temperature solder

180 – 220°C

Lead-free high-temperature solder

220 – 250°C