Page 14

For technical questions, please call 1-888-866-5797.

Item 57336

SA

FE

TY

OP

ERA

TI

O

N

MAINT

ENANC

E

IN

ST

ALLA

TI

O

N

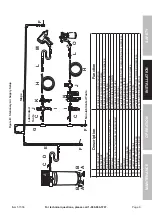

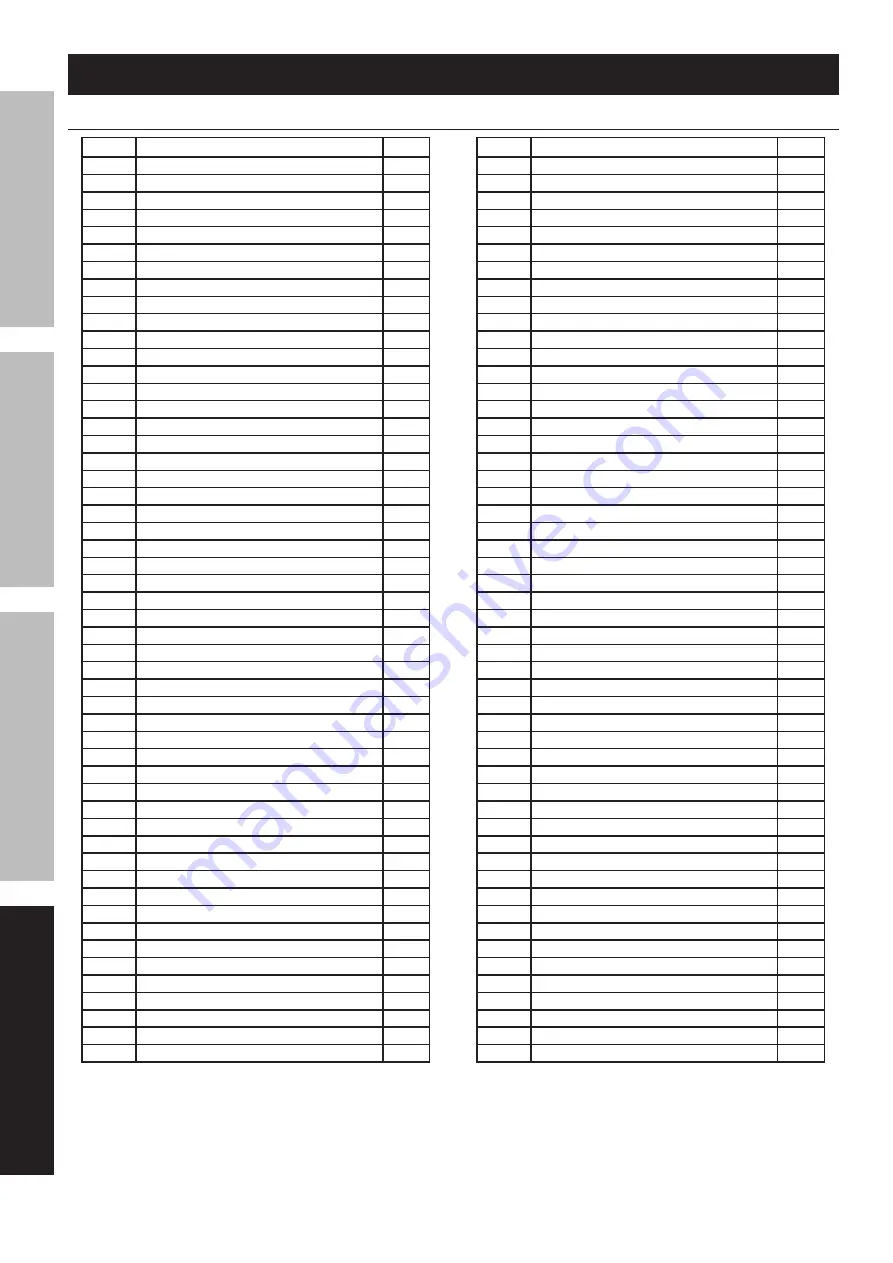

Parts List and Diagram

Parts List

Part

Description

Qty

1

Bolt M4

×

12

8

2

Washer

8

3

End Cover

2

4

Retainer Ring

2

5

Fan

1

6

Crank Saft

2

7

Bolt M8

×

8

4

8

Bearing

2

9

Connecting Rod

2

10

Bolt M5

×

20

2

11

Bolt M5

×

132

4

12

Spring Washer

4

13

Washer

4

14

Rubber Cushion

4

15

Crank Case

2

16

Cable Bracket

1

17

Washer

10

18

Bolt M4

×

5

2

19

Wire Clip

1

20

Wire

1

21

Nut M4

1

22

Locking Washer

1

23

Bolt M4

×

12

1

24

Bearing

2

25

Stator Sleeve

1

26

Stator Assembly

1

27

Flat Key

2

28

Rotor Assembly

1

29

Plug

1

30

Nut M5

4

31

Fan

1

32

Piston Ring

2

33

Press Block

2

34

Washer

2

35

Bolt M6

×

16

2

36

Gasket

2

37

Cylinder

2

38

Cylinder Seal

2

39

Bolt M4

×

6

2

40

Reed Valve

4

41

Valve Plate

2

42

Reed Valve Limit Block

2

43

Bolt M4

×

8

6

44

Cylinder Head Seal

2

45

Cylinder Cap

2

46

Washer

8

47

Spring Washer

8

48

Bolt M6

×

70

8

49

T-Cock

1

50

Easy-Start Valve

1

51

Seal

4

52

Tube

2

Part

Description

Qty

53

Cylinder Head Guard Limit Block

2

54

Cylinder Head Guard

2

55

Screw

4

56

Air Filter

2

57

Soft Pipe

2

58

Tank Assembly

1

59

Bolt M12

×

80

2

60

Washer

4

61

Wheel

2

62

Wheel Axle Sleeve

2

63

Nut M12

2

64

Nut M6

2

65

Rubber Foot

2

66

Washer

12

67

Bolt M6

×

20

2

68

Drain Valve

1

69

Nut M8

4

70

Bolt M6

×

14

10

71

Bolt M8

×

30

4

72

Nut M8

4

73

Cap Nut M8

4

74

Funnel

2

75

Tube Nut

1

76

Exhaust Pipe

1

77

Tube Nut

1

78

Power Switch

1

79

Power Cord

1

80

Handle Grip

1

81

Frame Assembly

1

82

K Nut

8

83

Outlet Pipe

1

84

Tube Nut

2

85

Funnel

2

86

Bushing

2

87

Elbow

2

88

Safety Valve

1

89

Pressure Regulator

1

90

Tank Pressure Gauge

1

91

Outlet Pressure Gauge

1

92

Air Outlet

2

93

Plug

3

94

Panel

1

95

Capacitor Case

1

96

Capacitor

1

97

O-Ring

2

98

Bottom Plate

1

99

Seal

2

100 Intake Manifold

1

101 Check Valve

1

102 Wire Clip

1

103 Wire

1

104 Hook

1