Operation Maintenance Manual

Safety Spinning Wrench

PN 9GV73109 - Revision: 02 2018-05

46

C

O

M

M

IS

SION

IN

G

/

O

PE

R

A

TION

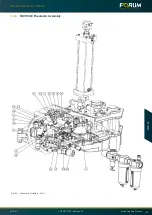

4.2.1

Positioning and clamping the

SSW-40

1. Locate the lift handle

q

. Raise the SSW-40 to the

proper position, about 12” above the tool joint.

2. Position the SSW-40 on the pipe upset or tool joint.

3. Proper clearance is ½” between the pipe and the front

rollers.

4. Turn the adjustment screw to engage the socket.

Proper clearance is ½” between the pipe and the front

rollers.

5. Turn the adjustment handle either clockwise or

counter clockwise to close the distance between the

bodies or to open it up.

6. Push the clamp control

w

to clamp down on the pipe.

7. Pull the clamp control

w

lever to unclamp the pipe

and then swing the SSW-40 away from the pipe.

4.2.2

Motor Direction

1. Position the lockout

q

to spin in the desired direction,

spin in or spin out.

2. The lockout will prevent spinning in the undesired

direction.

3. Push the throttle control lever

w

to spin in or

pull to spin out.

Handling the adjustment screw

1. Pull out the adjustment handle out of the adjustment

screw

q

.

2. Fold over the adjustment handle at the joint.

3. Set the necessary diameter while turning the handle

clockwise or anticlockwise

w

.

4. Follow the adjustment operation in reverse order, after

setting the necessary diameter.

CAUTION

Only operate the SSW-40 when adjustment

handle is hidden in the adjustment screw.

Fig. 31: Positioning valve of the SSW-40

Fig. 32: Spinning direction valve

Fig. 33: SSW-40 Adjustment screw

q

w

w

q

q

w