Note.

The condenser probe is no longer fitted as in previous model.

The ‘Condenser Clean’ and ‘Service Due’ warnings will not be displayed as the parameters are set to ‘0’ and

therefore switched off.

The diagnostics is no longer incorporated as in previous models so functions SF010, SF020 and SF030 will not be

displayed.

Service Adjustments

The controller has three ‘Service’ modes – the Output Relay Test function, the Model Selection Function and the

individual Parameter adjustments. These features are accessible only from the ‘Service Main Menu’.

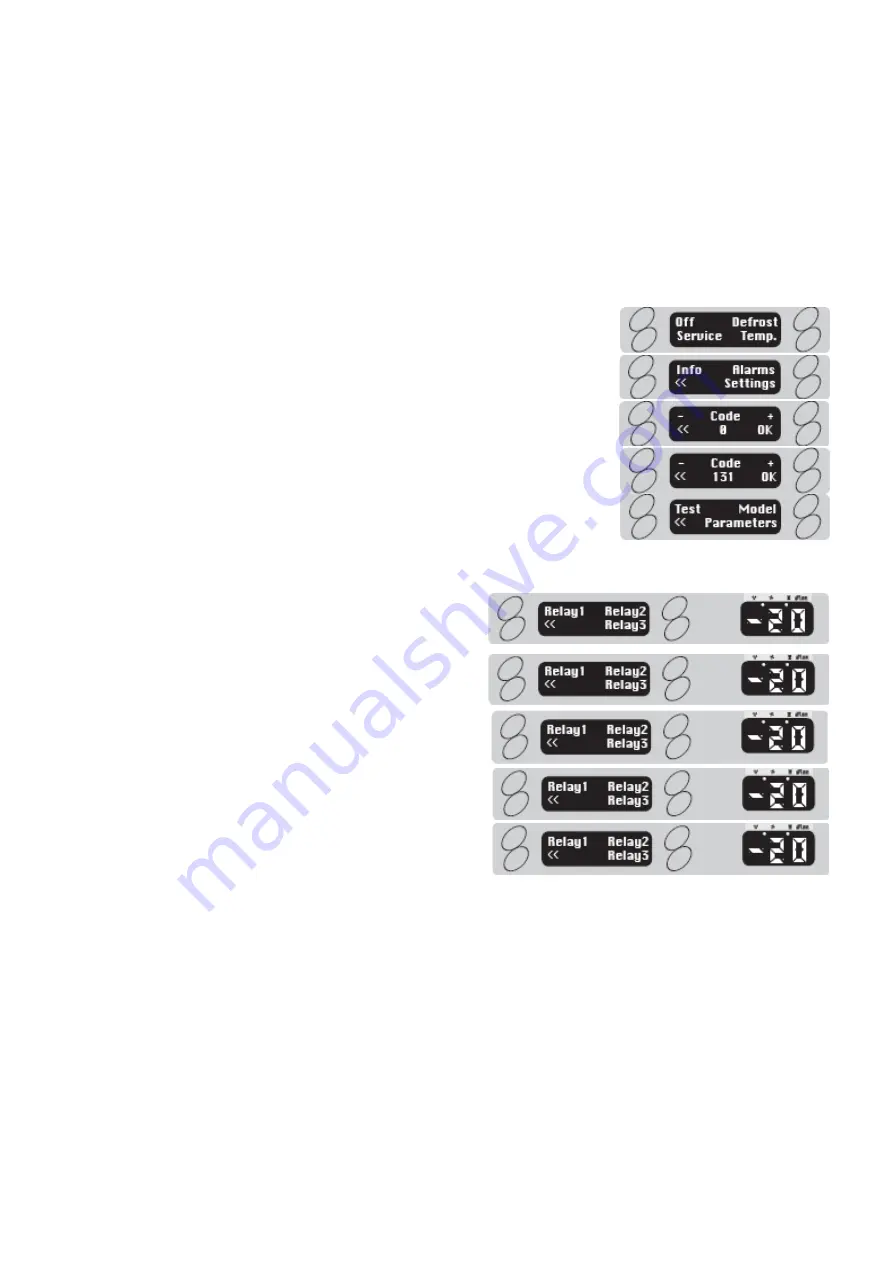

Service Main Menu.

Press any button (1, 2, 3 or 4)

Press button 4 ‘Service’ for the ‘Service Menu’.

Press button 3 ‘Settings’ for the ‘Settings Menu’.

Press button 2 ‘+’ to advance the code number to ‘131’ if you go beyond

the number press button 1 ‘-‘ to lower to the correct number.

Press button 3 ‘OK’ to enter the ‘Service Main Menu’.

To exit the ‘Service Main Menu’ and return to the ‘User Main Menu’ press

button 4 ‘<<’. If no further buttons are pressed for one minute the

controller will revert to the normal operating mode.

Out-Put Relay Test

Whilst in the ‘Service Main Menu’ press button 1 ‘Test’ all

relays will de-energise and the screen opposite will be

displayed.

To test relay 1 ‘Condensing Unit Relay’ press button 1.

Relay 1 will energise.

To test relay 2 ‘Evaporator Fan Relay’ press button 2.

Relay 2 will energise.

To test relay 3 ‘Defrost System Relay’ press button 3.

Relay 3 will energise.

To test all three relay outputs press buttons 1, 2 and 3

together. All three relays will energise.

To exit the ‘Output Relay Test Menu’ and return to the ‘User Main Menu’ press button 4 ‘<<’. If no further buttons

are pressed for one minute the controller will revert to the normal operating mode.

Model Selection Function

The ‘Model Selection Function’ allows the controller to be set during manufacturing, or replacement, to the most

appropriate model range with the accompanying default setting values. There are eleven temperature default

models which are:- HIGH TEMP-D (High Temperature with Door Switch), HIGH TEMP (High Temperature without

Door Switch), LOW TEMP-GD (Low Temperature with Hot Gas Defrost and Door Switch), LOW TEMP-G (Low

Temperature with Hot Gas Defrost without Door Switch), LOW TEMP-ED (Low Temperature with Electric Defrost

and Door Switch), LOW TEMP-E (Low Temperature with Electric Defrost without Door Switch), MEAT TEMP-GD

(Meat Temperature with Hot Gas Defrost and Door Switch), MEAT TEMP-G (Meat Temperature with Hot Gas

Defrost without Door Switch), FISH TEMP. (Fish Temperature without door switch), WINE TEMP. (Wine

Temperature with door switch), HEATED CAB. (Heated Temperature without door switch).

All controllers arrive from the manufacturer with the HIGH TEMP-D settings if any other setting is required the

following procedure should be followed.

7

Summary of Contents for EPREM 1/2H

Page 1: ...EPREM CABINET COUNTER ISO 14001 ISO 9001 ...

Page 15: ...Wiring Diagrams 14 ...

Page 16: ...15 ...

Page 17: ...16 ...

Page 18: ...17 ...

Page 19: ...18 ...