Section P

Page 5

Vista 248/268 Owners Manual

03/00

This is due to the paints chemical emission that in turn

retards marine growth. When this occurs, refinishing is

in order.

Four Winns® recommends reapplication of the antifoul-

ing paint seasonally. The effectiveness of the paint will

be drastically reduced if used longer. Though

Four Winns® has found the antifouling paints used to

provide good marine growth protection in most water,

other paints may be more effective in certain water con-

ditions. See a Four Winns® dealer for recommendations

on antifouling paint use in your area.

NOTICE

During surface preparation, the hull should be

sanded only enough to remove any foreign mat-

ter, and loose paint. DO NOT sand deeply into

the gel coat, fiberglass cosmetic problems could

later result. After sanding, the surface should

be wiped with a rag treated with a cleaner recom-

mended by the antifouling paint manufacturer.

The surface must be clean and slightly rough to

ensure paint adhesion.

Prior to application of the antifouling paint, the boat owner

may consider coating the hull bottom with an epoxy coat-

ing. Four Winns® recommends this procedure as a pre-

ventive and effective means of controlling osmotic blis-

tering. Most major antifouling paint manufacturers also

supply a line of epoxy undercoatings. Consult your Four

Winns® dealer for recommendations on epoxy under-

coatings.

P - 7

HULL SUPPORT

Proper support of the hull while it is out of the water is

imperative. Due to the design complexities, Four Winns®

does not recommend trailers or storage cradles be home-

made. The boat is a valuable piece of equipment. DO

NOT risk permanent damage to the hull structure in an

attempt to save the cost of an adequate support. Improp-

er support can lead to serious and permanent hull defor-

mation.

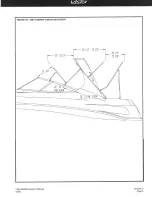

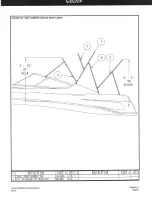

While lifting the boat, ensure slings are in the

proper locations as indicated by the sling loca-

tion labels .

Failure to do so may result in

permanent hull structure damage and will

invalidate the hull structure warranty.

NOTICE

Improper repair techniques can lead to further

fiberglass component damage.

C.Osmotic Blistering

Osmotic blistering or boat pox is an unfortunate but

not uncommon occurrence in fiberglass boats. Fiber-

glass is water retardant, not waterproof. When a boat

is left in the water for a period of time, the fiberglass will

absorb water. It is a natural process that can not be

eliminated in production methods or material selection

and usage. However, there are ways to control and

possibly prevent blisters (see Section P-6). If you do

encounter blisters, be assured that the blisters are

merely cosmetic. They do not indicate a defect in the

boat structure or lamination. Four Winns®, along with

most boat manufacturers, regard gel blisters as a stan-

dard maintenance item.

The repair procedure for gel coat blisters is similar to

the procedures outlined in the previous section on cracks

and gouges. There is an exception however, in that the

hull must dry out for several days or possibly weeks

before repairs can proceed.

To determine if the hull has dried sufficiently, tape one

square foot of household plastic wrap securely to the

hull bottom. Make sure all edges are sealed and let it

stand for twenty-four hours. If condensation has accu-

mulated under the plastic, the hull is still wet and must

be allowed to dry longer before repairing.

When the repair is completed, an application of an ep-

oxy barrier coat should be considered. This will help

prevent the possibility of reoccurrence of blisters. Your

Four Winns® dealer or local ship store will have informa-

tion on barrier coat products.

P - 6

ANTIFOULING PAINT

Four Winns® recommends antifouling or bottom paint

for boats which will be kept in the water for extended

periods of time. Antifouling paint reacts with water to

retard the growth of algae, barnacles and other marine

growth on the hull. In addition to marine growth, it of-

fers protection against excessive water pollution.

Antifouling paint begins reaction upon contact with wa-

ter. After a seasons use or sooner under certain condi-

tions, the antifouling paint may appear to be dissolving.

Summary of Contents for 248 Vista

Page 1: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 81: ...Section J Page 10 Vista 248 268 Owner s Manual 03 00 FIGURE J9 248V HEAD...

Page 82: ...Section J Page 11 Vista 248 268 Owner s Manual 03 00 FIGURE J10 248 FRESH WATER SYSTEM 1 OF 2...

Page 83: ...Section J Page 12 Vista 248 268 Owner s Manual 03 00 FIGURE J11 248 FRESH WATER SYSTEM 2 OF 2...

Page 84: ...Section J Page 13 Vista 248 268 Owner s Manual 03 00 FIGURE J12 248V WASTE SYSTEM 1OF 2...

Page 88: ...Section J Page 17 Vista 248 268 Owner s Manual 03 00 FIGURE J16 268V HEAD...

Page 89: ...Section J Page 18 Vista 248 268 Owner s Manual 03 00 FIGURE J17 268 FRESH WATER SYSTEM 1 OF 2...

Page 90: ...Section J Page 19 Vista 248 268 Owner s Manual 03 00 FIGURE J18 268 FRESH WATER SYSTEM 2 OF 2...

Page 91: ...Section J Page 20 Vista 248 268 Owner s Manual 03 00 FIGURE J19 268V WASTE SYSTEM 1 OF 2...

Page 92: ...Section J Page 21 Vista 248 268 Owner s Manual 03 00 FIGURE J20 268V WASTE SYSTEM 2 OF 2...

Page 99: ...Section L Page 4 Vista 248 268 Owner s Manual 03 00 Figure L7 248 268V Air Conditioning System...

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 127: ......

Page 128: ......

Page 129: ......

Page 130: ......

Page 131: ......

Page 152: ......

Page 153: ......

Page 154: ......

Page 155: ......

Page 156: ......

Page 157: ......

Page 158: ......

Page 167: ......