25

Calibration

Full Calibration, Toxic Gas Sensors

The correct voltage output for the target gas being used can be determined as follows:

(16 x gas concentration) / range of 4 x 10mV

a. Example: Calibrating a hydrogen sulfide sensor to a range of 0-50ppm using a

calibration gas concentration of 20ppm:

(16 x 20) / 50 + 4 + 10 = 104 mV

12. With the correct reading displayed on the detector calibration is complete, re-assemble the

detector.

Caution: Be sure to remove the calibration nose before placing the detector into service

.

Never operate the sensor with the calibration nose inserted.

Caution: If the sensor or detector will not allow you to fully adjust the displayed

concentration to match that of the calibration gas then you must replace the gas sensor.

Full Calibration, Oxygen Sensors

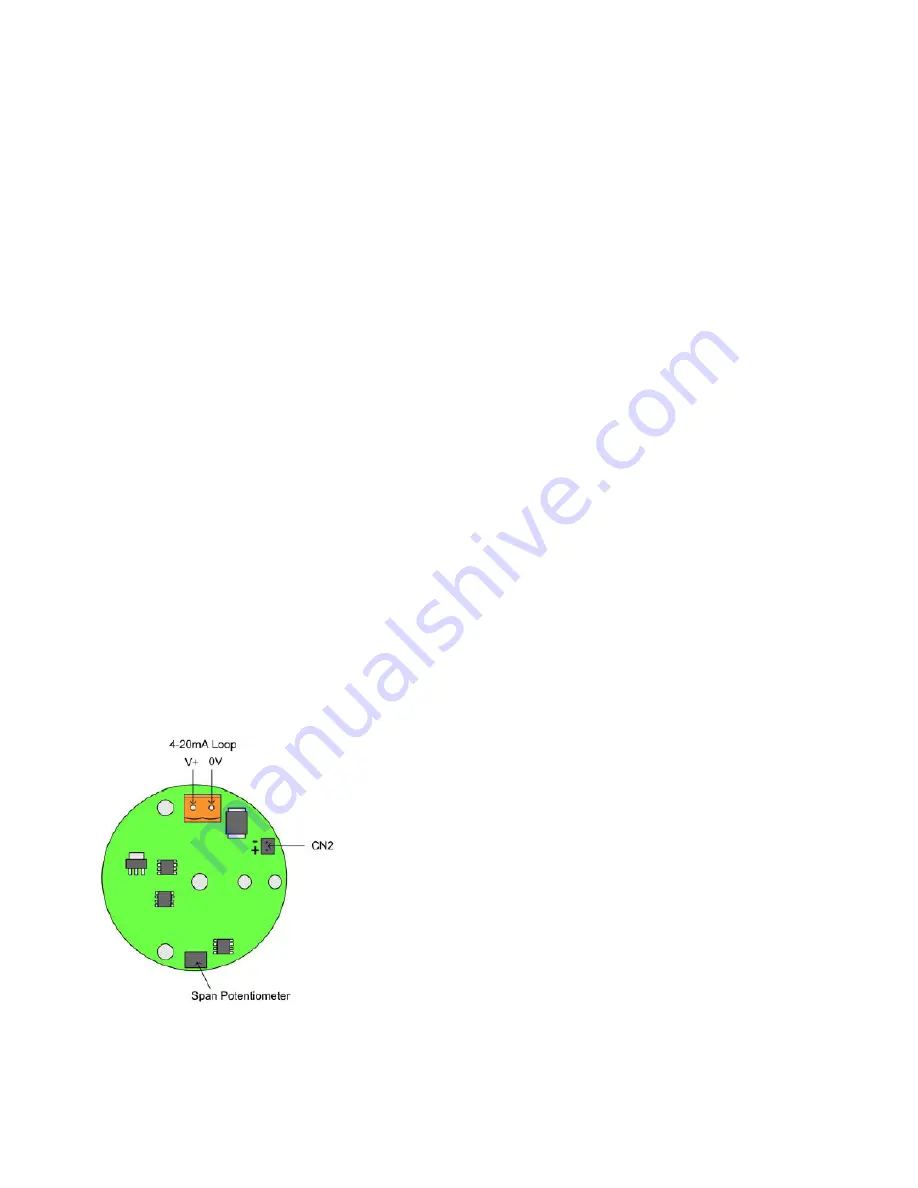

Calibration should be carried out in ambient air, and is done simply by adjusting the span potentiometer

until a reading of 20.9% on a scale of 0-25% is displayed on the LED display. Zero point calibration is

not required. Sensor output can be monitored by connecting a multi-meter set to mA to the 4-20mA

loop connector, or to the millivolt connector CN2 using a meter set to VDC.

Oxygen sensors alarm as concentrations, and therefore sensor output, decreases. A 4 mA Oxygen

sensor output corresponds to 16% Oxygen by volume, which is the Danger alarm trip point.

1. Connect the meter leads, observing polarity, to millivolt

test connector CN2 or to the 4-20mA loop connector. Make sure

your meter is set to the correct scale.

2. Ensure that the calibration nose is removed, expose the

sensor to ambient air and allow sensor output to stabilize.

3. Using a small non-metallic screwdriver with a 1.2 x 0.5

mm tip, adjust the span potentiometer until a reading of 17.4 mA

is shown (or 174 mV across CN2). These values correspond to

20.9% O2 on a scale of 0-25%.

4. The calibration is now complete.

5.

To test the alarm functions see the following section

“Sensor Response (Bump) Test. This test requires

a mixture of

16% Oxygen with the balance in Nitrogen and a 0.5 LPM fixed

flow rate regulator with C10 connection.