7

ENGLIS

H

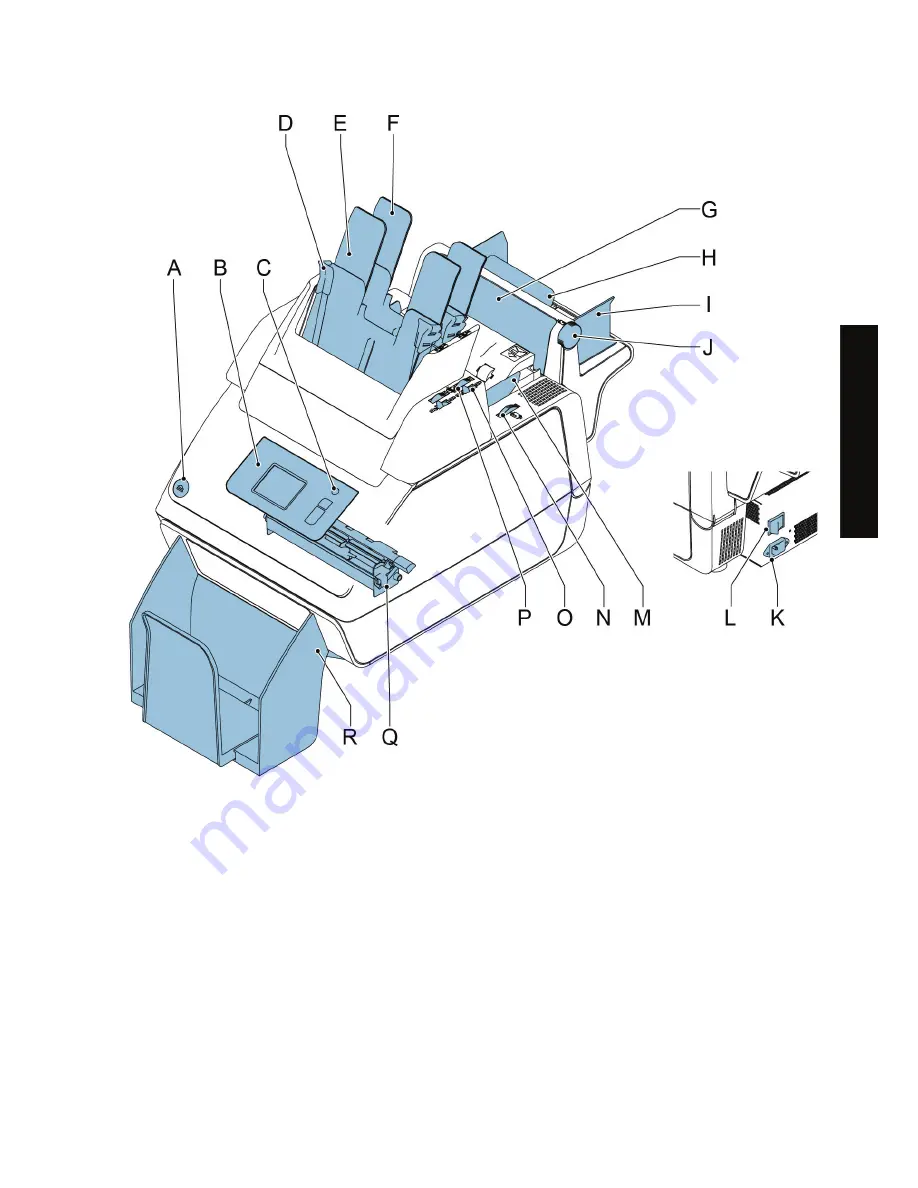

2.2

Operating Controls

A

button to open the system

K

power inlet

B

control panel with touch screen

L

power switch

C

standby button

M

side guides envelope hopper

D

paper guides

N

thumb wheel for adjusting side guides

envelope hopper

E

document feeder 1

F

document feeder 2

O

locking lever for side guides of document

feeder tray 2 and for filling tray 2

G

flap, for access to document path

of feeder 3

P

thumb wheel for adjusting side guides

H

support feeder 3

document feeder tray 2

I

side guides feeder 3

Q

sealing liquid reservoir

J

thumb wheel to adjust side guides

feeder 3

R

catch tray

Summary of Contents for All in One Printer

Page 1: ...USER S GUIDE ...