IN 3H06/08/12/15

- 9 -

© Future Products Group

Preparation

HEATED CABINETS

-

OPERATION

Shelf Location

and Ticketing

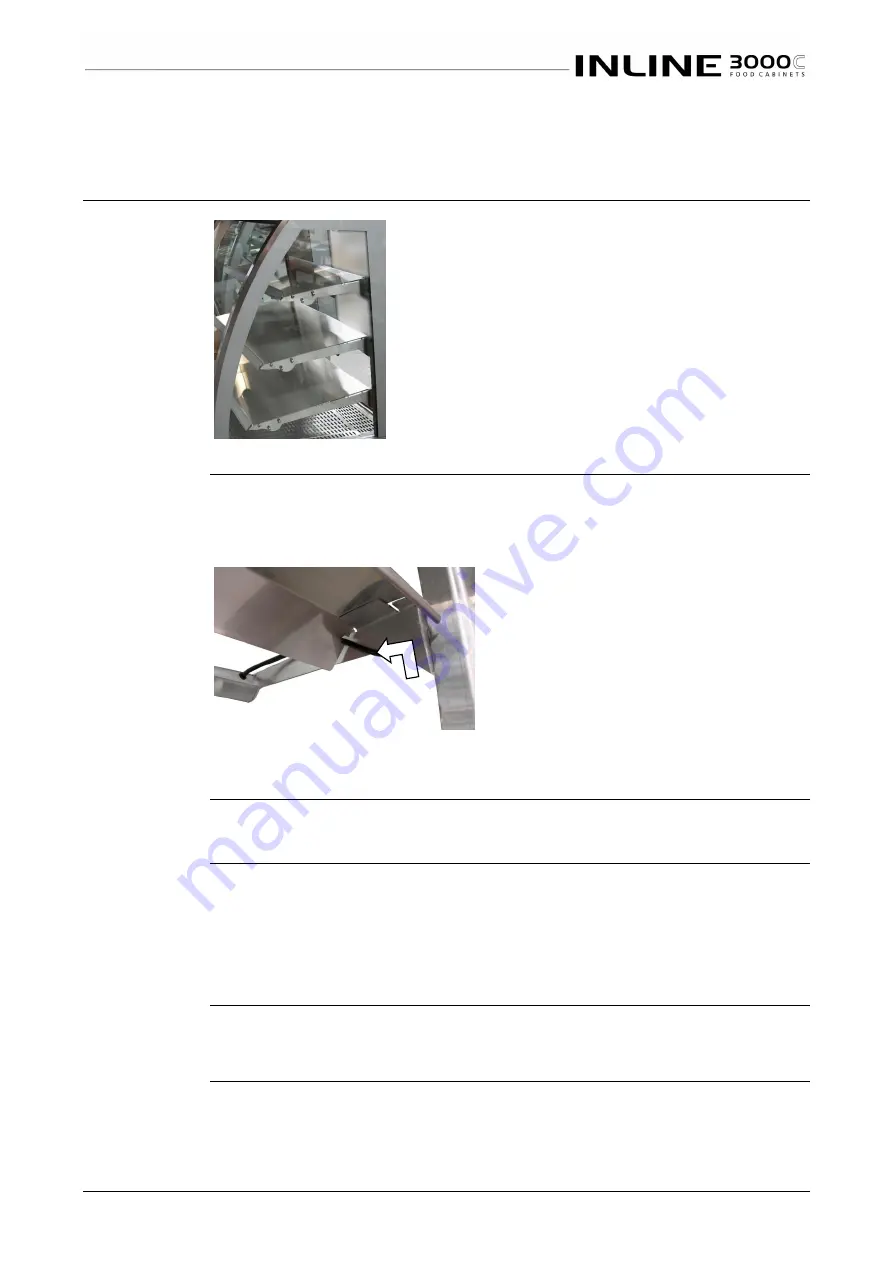

All shelves are adjustable in height and can easily be

moved up or down, to match product size.

If shelf lights are fitted, the movement is restricted to

50mm, because of the electric cables to the lights.

For greater movement contact the manufacturer or

supplier for advice, as electrical modifications may be

required.

Wire shelf racks are supplied as standard, but trays,

as shown, are available to order.

The front and rear edges of the shelves are profiled to

carry ticketing/labels.

Shelf

Adjustment

To move the shelf brackets, first remove the sliding doors and the shelf trays.

Using two people, one on each bracket, lift the brackets straight up firmly and

then pull the brackets forward, to disengage them from the slots in the support

posts.

Insert the brackets into their new position,

and push bracket down firmly.

The brackets may be positioned to give

two different degrees of slope to the

shelves.

Refit all shelf trays and doors

.

N.B.

Make sure brackets are pushed down as far as they can go. Failure

to do this may result in shelf collapse, when loaded with product.

Power Supply

Ensure that power is connected to the cabinet.

Set the

Temperature

Set the thermostat to the desired temperature, 75 degrees Celsius is the

recommended setting to maintain food temperature within food safety

guidelines.

NOTE

Setting the dial to a higher temperature than required will not speed up

the heating process.

Set it to the desired temperature.

Fumes and

Odours

Before use, operate the cabinet for 4 hours to remove any fumes or odours,

which may be present. This will avoid possible tainting of food.

Continued on next page