IN 4C 08/12/15/18

- 21 -

© Future Products Group

SERVICING

Control Gear

REFRIGERATED CABINETS

-

SERVICING

Location

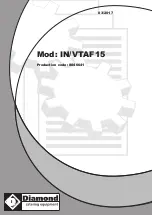

The electrical control gear is located in the top

of the cabinet.

Remove the top plate to access the control

gear.

The chassis has power supplies for the lights,

a phase-shift capacitor for the evaporator fan,

the refrigeration and cabinet controller and two

protective fuses.

Lighting

REFRIGERATED CABINETS

-

SERVICING

Caution

Do not service lights without isolating the cabinet from the mains supply.

Test Lighting

Components

Before replacing an LED strip, check that the power supply is working.

If there is no dc voltage at the output, the power supply should be replaced.

If there is a dc output, the LED strip must be replaced.

Access to LED

Strips

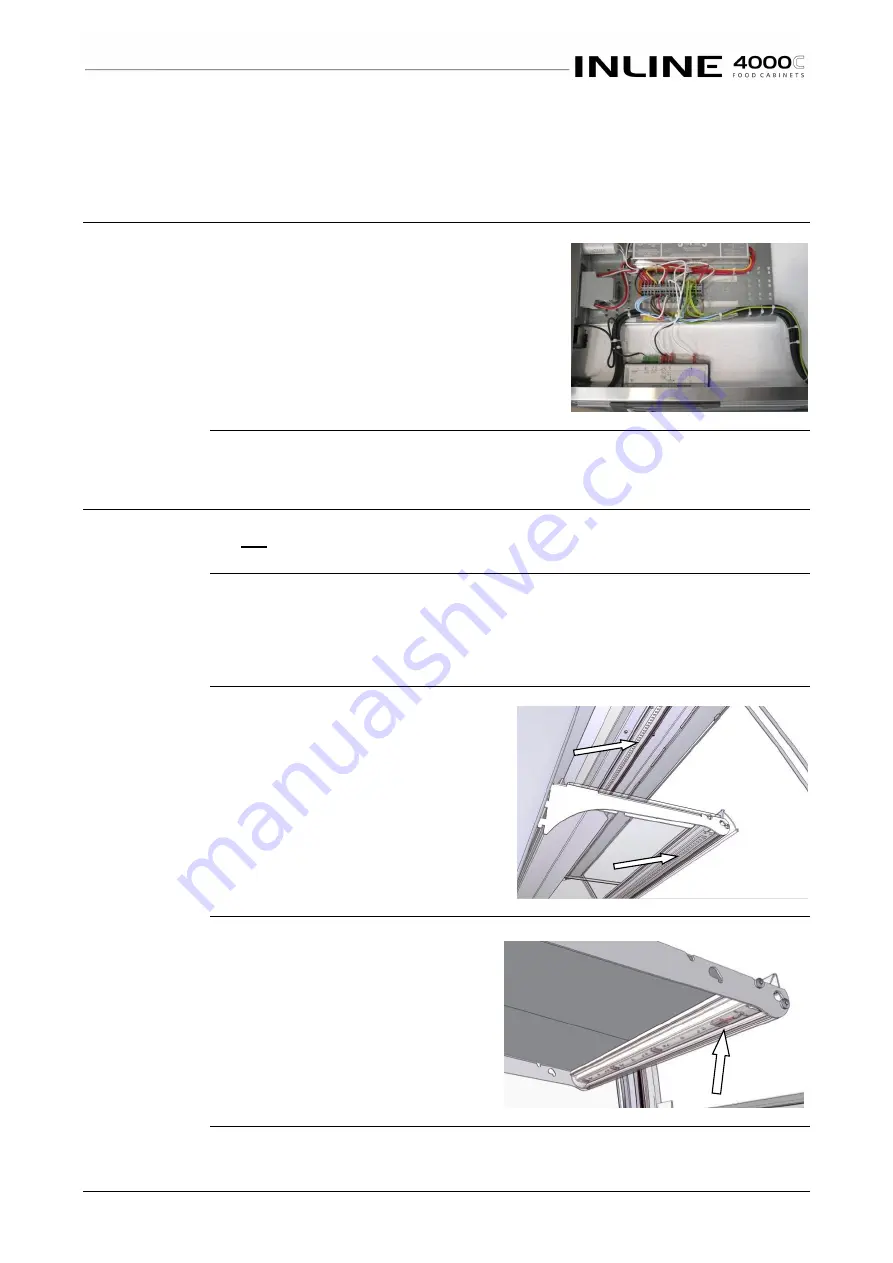

The LED strips are protected with

plastic covers. These clip into grooves

in the aluminium extrusion.

Remove the plastic cover to access the

LED strip.

The top light assembly is different from

the shelf lights, so the correct

replacement unit must be used.

LED Strip

Replacement

Individual LED modules cannot be

replaced. A complete light unit must

be used.

Connection is made with a plug and

socket. Disconnect the supply lead

from the faulty unit, and reconnect it

to the replacement unit.

Replace the plastic cover.