Part No. 27221 Rev. G October 2019

- 20 -

5000 Series Open Front Cabinets

Dixell Controller

HEATED CABINETS

-

SERVICING

Temperature

Regulator

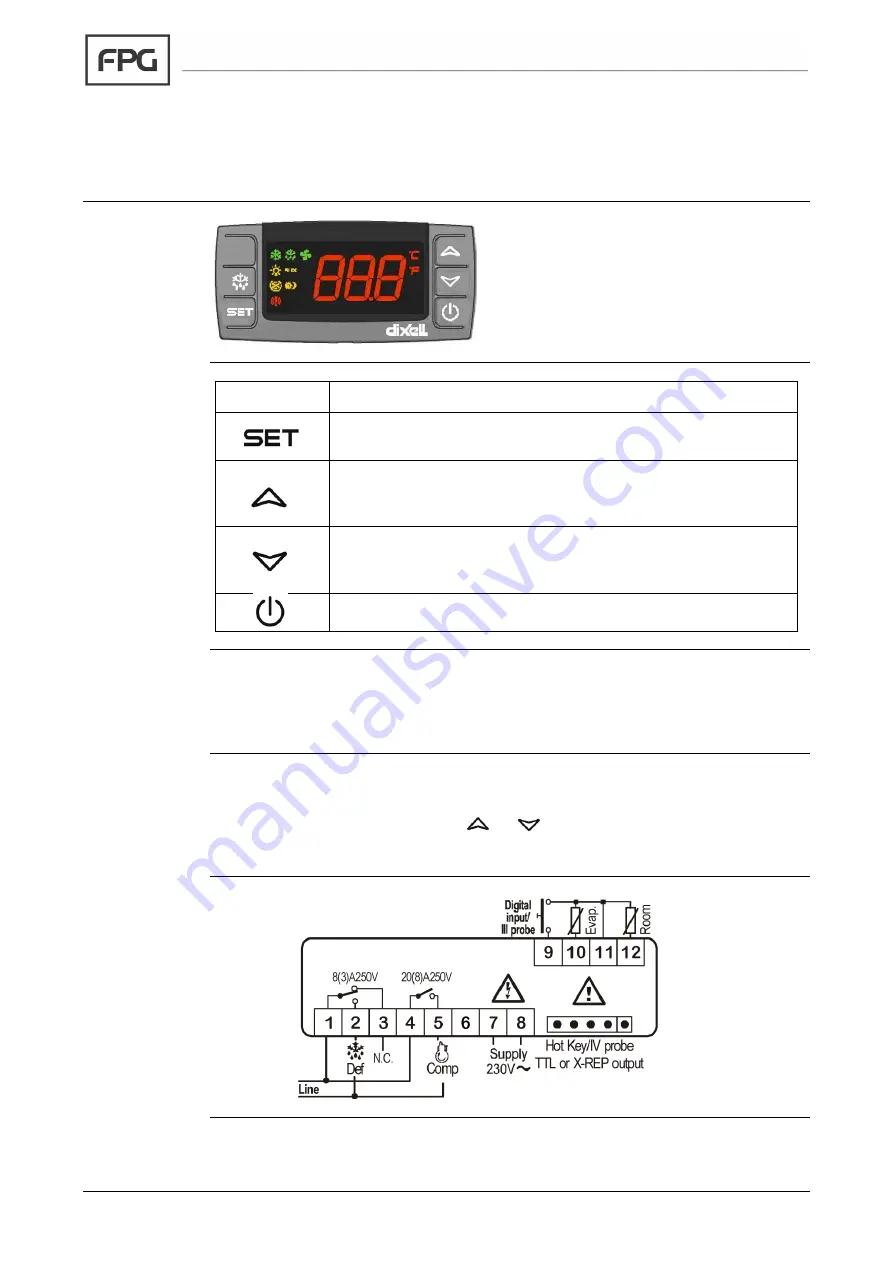

XR20CX

Model XR20CX is a microprocessor based

controller.

In this application it is configured as a

heating controller, and unwanted functions

are disabled.

XR20CX Key

Functions

KEY

FUNCTION

To display target set point; in programming mode it selects

a parameter or confirm an operation

(UP): To see the max. stored temperature; in

programming mode it browses the parameter codes or

increases the displayed value

(DOWN): To see the min stored temperature; in

programming mode it browses the parameter codes or

decreases the displayed value

To switch the instrument off, if onF = oFF. Not enabled

XR20CX

Display the Set-

point

To show the set-point value, press and immediately release the

SET

key.

Press and immediately release the

SET

key or wait for 5 seconds to display the

probe temperature again.

XR20CX

Change the

Set-point

To change the set-point value, press the

SET

key for more than 2 seconds;

The value of the set-point will be displayed and the °C or °F LED starts blinking;

To change the set value push the

or

arrows within 10s.

To memorise the new set-point value push the

SET

key again or wait 10s.

XR20CX

Connections

Summary of Contents for INLINE 5000C Series

Page 1: ...Heated Open front Cabinets Curved and Square Formats...

Page 28: ...Part No 27221 Rev G October 2019 28 5000 Series Open Front Cabinets IN 5H06 5H08 5H12 OF SQ...

Page 29: ...IN 5H06 08 12 OF 29 Future Products Group...

Page 30: ...Part No 27221 Rev G October 2019 30 5000 Series Open Front Cabinets...