8 - Maintenance and Servicing

To prolong the service life and performance of your searchlight, the following maintenance

guidelines are recommended:

◼

Maintenance checks should be conducted before every voyage or at least every three

months.

◼

Before checking, disconnect the equipment from the supply.

◼

Visually inspect the condition of the equipment.

◼

Any major or minor structural damage should be rectified immediately to reduce

sympathetic wear.

◼

Check Filters fitted to the top and bottom vent boxes. Remove the louvred covers and slide

out the filters to check the condition.

◼

After inspection it may be necessary to clean the inside of the searchlight. The following

procedure should be adhered to:

◼

Remove the front bezel.

◼

Clean the front glass inside and out using a proprietary glass cleaner.

◼

Clean the reflector if required.

◼

Check the reflector mounting gaskets. If signs of corrosion or damage are

evident, replace as necessary.

◼

Ensure that the lampholder is free from corrosion or other damage.

◼

Check earth point for conductivity.

◼

It is advisable to check all seals and gaskets for signs of degradation. Renew if necessary.

◼

Upon completing all maintenance requirements, the searchlight should be tested for full

working order (approximately 20 minutes).

If in any doubt as to the correct servicing procedures to adopt, please contact your

distributor/agent or the manufacturer who will be able to advise the best course of

action for your product.

Summary of Contents for A7290

Page 6: ......

Page 7: ......

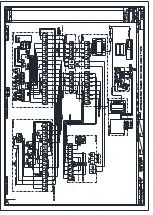

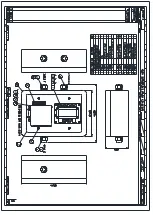

Page 8: ...Remove front panel for AC DC wiring connections Back To Top...

Page 9: ...INPUT 4 CORE 2 5mm TE2 50mm WELDING CABLE S50 2 CORE 1 5mm D1...

Page 10: ......

Page 15: ......

Page 22: ...FBUS Speed Control Board...

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......