clockwise.

- if the flame is too high, reduce the flame by turning the

setting screw (# 2) counter clockwise.

High setting (Refer to # 3, fig. 12) :

- set the regulating knob on “6" and let the burner run

for a few minutes. The flame must be shaped like a cone

and reach the upper part of the door.

- if the flame is too low, increase the flame by turning the

setting screw counter clock wise.

- if the flame is too high, reduce the flame by turning the

setting screw clockwise.

Please note - Very important : The adjustments of the

float regulator are very sensitive. The high and the low

setting screws must never be turned more than a 1/4 of

a turn at a time in any direction from their initial setting.

When making any adjustments, allow 3 to 5 minutes

between adjustments to allow burner to stabilize to

previous adjustment before proceeding, if necessary.

2.11. Chimney draught

Once the stove has been properly installed, the

chimney draught must be checked.

The adjustment of the draught will be made with the

barometric damper located at the back of the stove

(# 1, fig. 12).

The reading of the draught must be done once the unit

is hot (minimum 30 minutes of use).

Refer to the specifications p. 3 for minimum draught

requirement on low setting and on high setting.

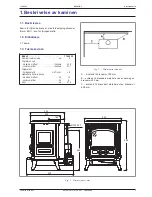

2.12. Door closing pressure

The closing latch rotates around a pressure screw

positioned cam (fig. 13).

- Loosen pressure screw 1.

- Turn cam to desired position 2.

- Tighten pressure screw 1.

2.13. Maintenance of the Chimney

Chimney and chimney connector should be inspected

at least once every three months during the heating

season to determine if a soot build up has occurred. If

soot has accumulated, it should be removed to reduce

the risk of a chimney fire.

1

2

Figure 13 - Door closing pressure

1 - Pressure screw

2 - Cam

Document n° 979-3 EN ~ 28/02/2000

Oil fired stove

BELFORT

174 05 05

Technical manual

7