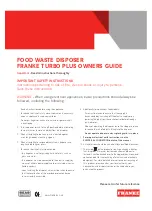

A

Press firmly around the cushion ring to ensure it is engaged

with the neck of the disposer.

B

lubricate the top inside lip of the rubber cushion ring with a

liquid soap.

C

line up discharge elbow of disposer with trap under mounting

assembly (see 5A). Guide disposer up and engage the GROOVE

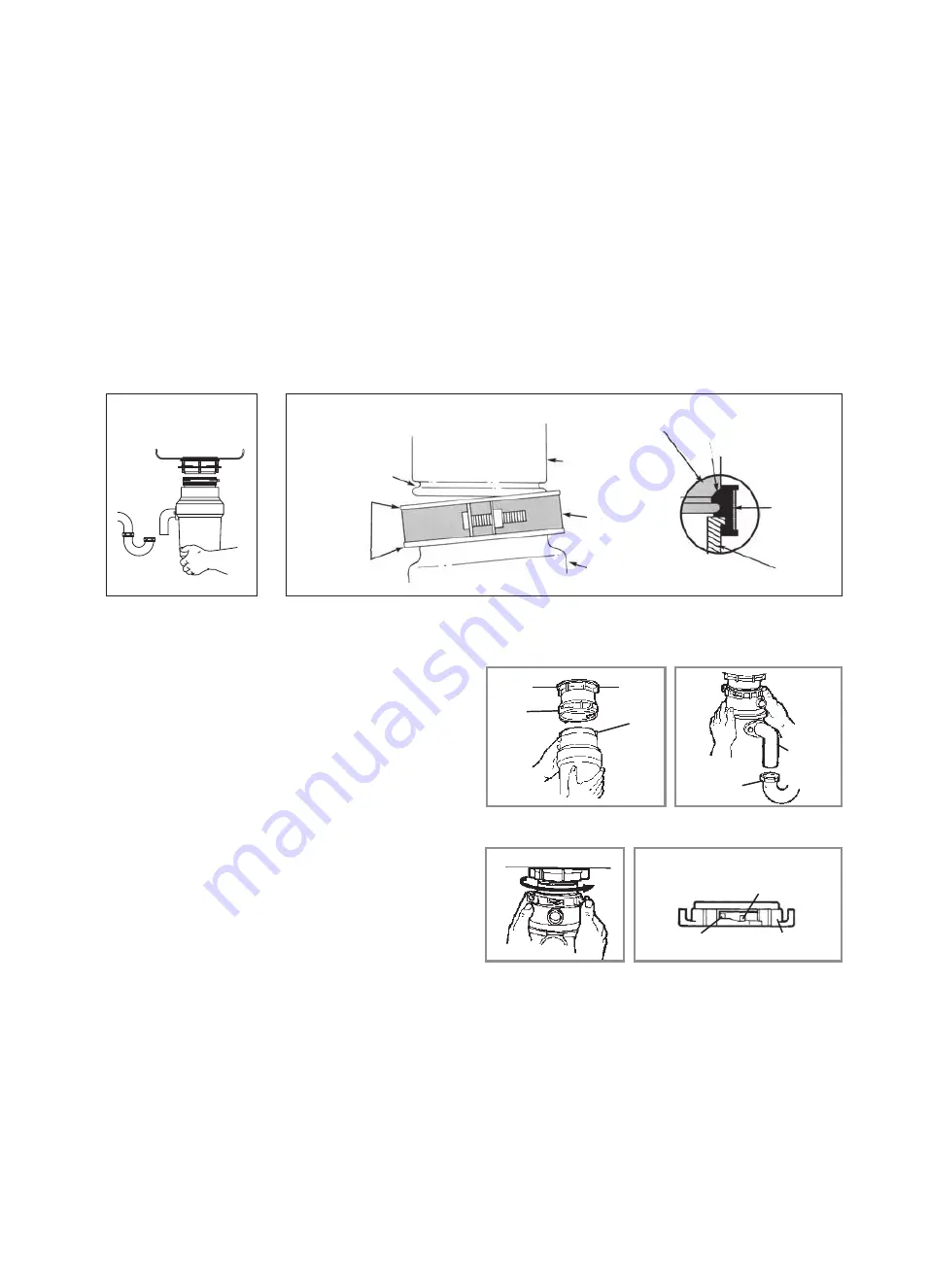

A

line up disposer under mounting assembly. Guide hopper

projections into mount ring slots. Turn mount ring about 1/4”

to right so that disposer is temporarily supported (see 6A).

B

Turn mount ring and disposer until disposer elbow lines up

with trap (see 6B).

C

Turn mount ring to the right (counter-clockwise)until it locks up

tight. Tap the mount ring ears with a hammer until the lock

position is achieved. Hopper projections must be to extreme

left of mounting slots (see 6C & 6D).

D

If mount ring is hard to turn, you may add a small amount of

petroleum jelly or liquid soap to hopper projections. Run water

and check for leaks.

of the cushion ring around the RIDGE at the bottom of the

sink flange (see 5A & refer back to 2B). While still supporting

the disposer, tighten the screw-clamp around cushion ring.

The disposer will now hang by itself.

D

If you need to turn the disposer make sure the sink flange does

not turn. It will break the seal created when installed.

5a. 3 BOLT mOuNT ASSEmBLy

For TP-50, TP-75 and TP-125 models.

5b. EZ mOuNT ASSEmBLy

For TP-125B models.

6B

SINK FLANGE

GROOVE

SINK FLANGE

CLAMP

HOPPER

SINK FLANGE

CUSHION

RING

CUSHION RING

TOP ANGLED SURFACE

HOPPER

CLAMP

6A

ImPORTANT PLEASE READ -

DO NOT REMOVE ClAMP FROM CUSHION RING OR CUSHION RING FROM HOPPER.

BOTH PARTS ARE FACTORY INSTAllED AND INSTAllATION READY

5A

5B

6B

ELBOW

TRAP

SLOT

PROJECTION

6A

6C

LOCKING DETAIL

HOPPER PROJECTION IN

“SUPPORTED” POSITION

HOPPER PROJECTION IN

“LOCK” POSITION

MOUNT

RING

6D