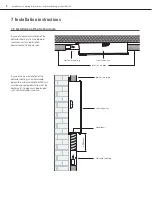

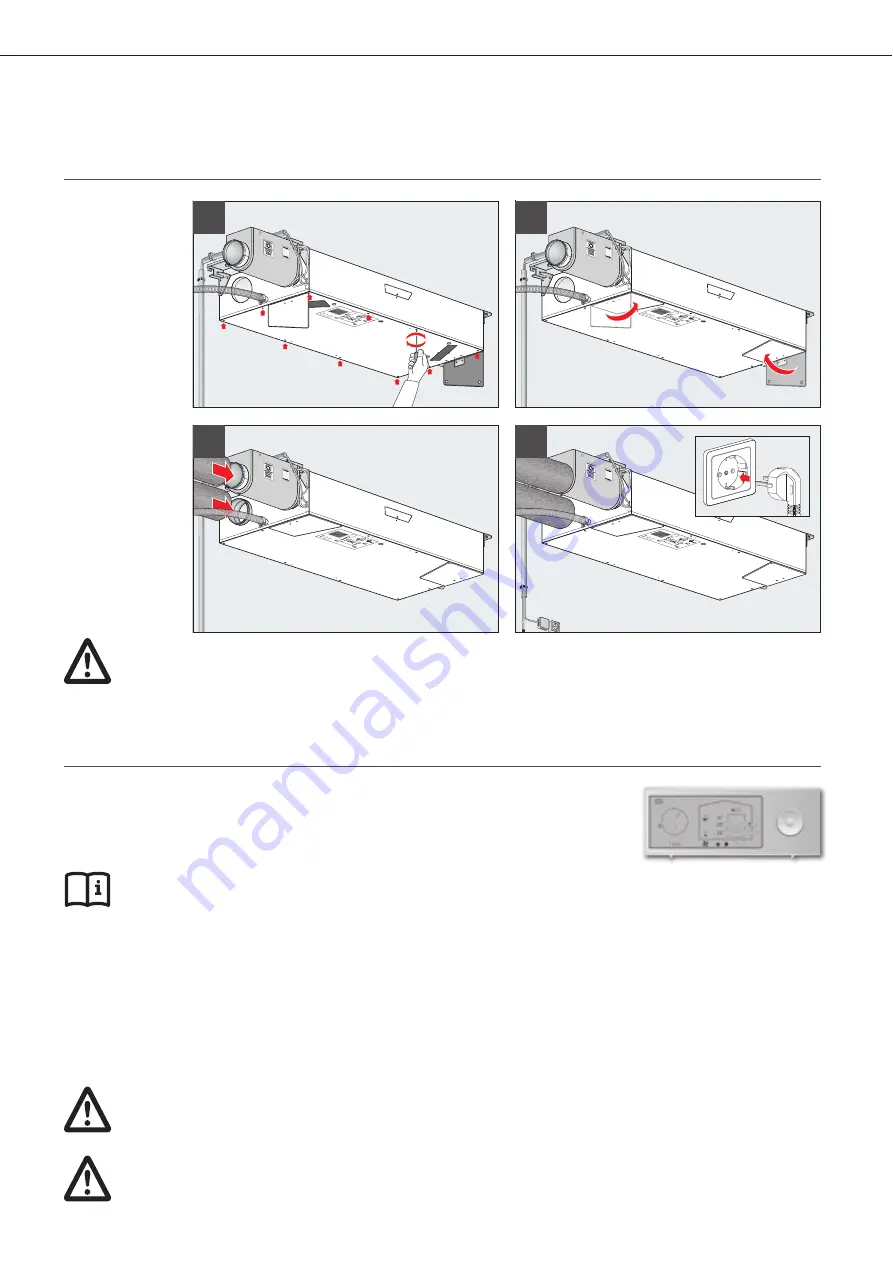

7.3 Installation of the defroster heating

7.4 Putting into operation

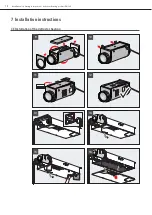

7 Installation instructions

The wireless remote control optionally available for the profi-air 180 flat ventilation unit is

required to put the defroster heating into operation.

The heating spiral must be regularly inspected during maintenance (prior to the beginning of the heating period). The defroster heating or

the ventilation unit must be disconnected from the network for maintenance work. If there is dirt on the heating spiral, it can be cleaned

with a suction nozzle and a vacuum cleaner.

For more information on putting into operation, see the 180 flat

wireless remote control operating instructions.

Do NOT clean the heating spiral with a dry or wet cloth.

After disconnection from the network, the heating spiral may still be hot.

Please allow it to cool sufficiently, otherwise burn injuries may happen.

Electrical connections must be established by authorised and qualified personnel and in the “dead” state of

the ventilation unit only. In addition, applicable local regulations and safety provisions must be complied with.

8 Maintenance and cleaning

B

Rechtsversio

n (B)

Right unit

unità destra

P1

P3

P4

P2

P1

→

P2

[Pa]

P3

→

P4

[m 3]

[Pa]

[m 3]

Einstellwe

rte / Calib

ration / Ca

librazione

0

120

100

80

60

40

20

110

90

70

50

30

10

0

60

40

100

160

140

200

20

80

120

180

[m 3/h]

[Pa]

Airflow

A / B

USB

Air/Luf

t

flo

w

B

Rechtsversio

n (B)

Right unit

unità destra

P1

P3

P4

P2

P1

→

P2

[Pa]

P3

→

P4

[m 3]

[Pa]

[m 3]

Einstellwe

rte / Calib

ration / Ca

librazione

0

120

100

80

60

40

20

110

90

70

50

30

10

0

60

40

100

160

140

200

20

80

120

180

[m 3/h]

[Pa]

Airflow

A / B

USB

Air/Luf

t

flo

w

B

Rechtsversio

n (B)

Right unit

unità destra

P1

P3

P4

P2

P1

→

P2

[Pa]

P3

→

P4

[m 3]

[Pa]

[m 3]

Einstellwe

rte / Calib

ration / Ca

librazione

0

120

100

80

60

40

20

110

90

70

50

30

10

0

60

40

100

160

140

200

20

80

120

180

[m 3/h]

[Pa]

Airflow

A / B

USB

Air/Luf

t

flo

w

B

Rechtsversio

n (B)

Right unit

unità destra

P1

P3

P4

P2

P1

→

P2

[Pa]

P3

→

P4

[m 3]

[Pa]

[m 3]

Einstellwe

rte / Calib

ration / Ca

librazione

0

120

100

80

60

40

20

110

90

70

50

30

10

0

60

40

100

160

140

200

20

80

120

180

[m 3/h]

[Pa]

Airflow

A / B

USB

Air/Luf

t

flo

w

27

28

25

26

Installation / operating instructions – defroster heating profi-air DN 125

12