49

MAINTENANCE

Troubleshooting

System Diagnostic Fault History

The SubDrive Connect continuously monitors system performance and can detect a variety of abnormal

conditions. In many cases, the drive will compensate as needed to maintain continuous system opera-

tion; however, if there is a high risk of equipment damage, the drive will stop the system and display the

fault condition. If possible, the drive will try to restart itself when the fault condition subsides. Each time

a fault is detected in the system, the drive records the fault with the date and time the fault was de-

tected. A maximum of 500 events are recorded and can be viewed and emailed using the FE Connect

mobile app.

Refer to

Diagnostic Fault Codes

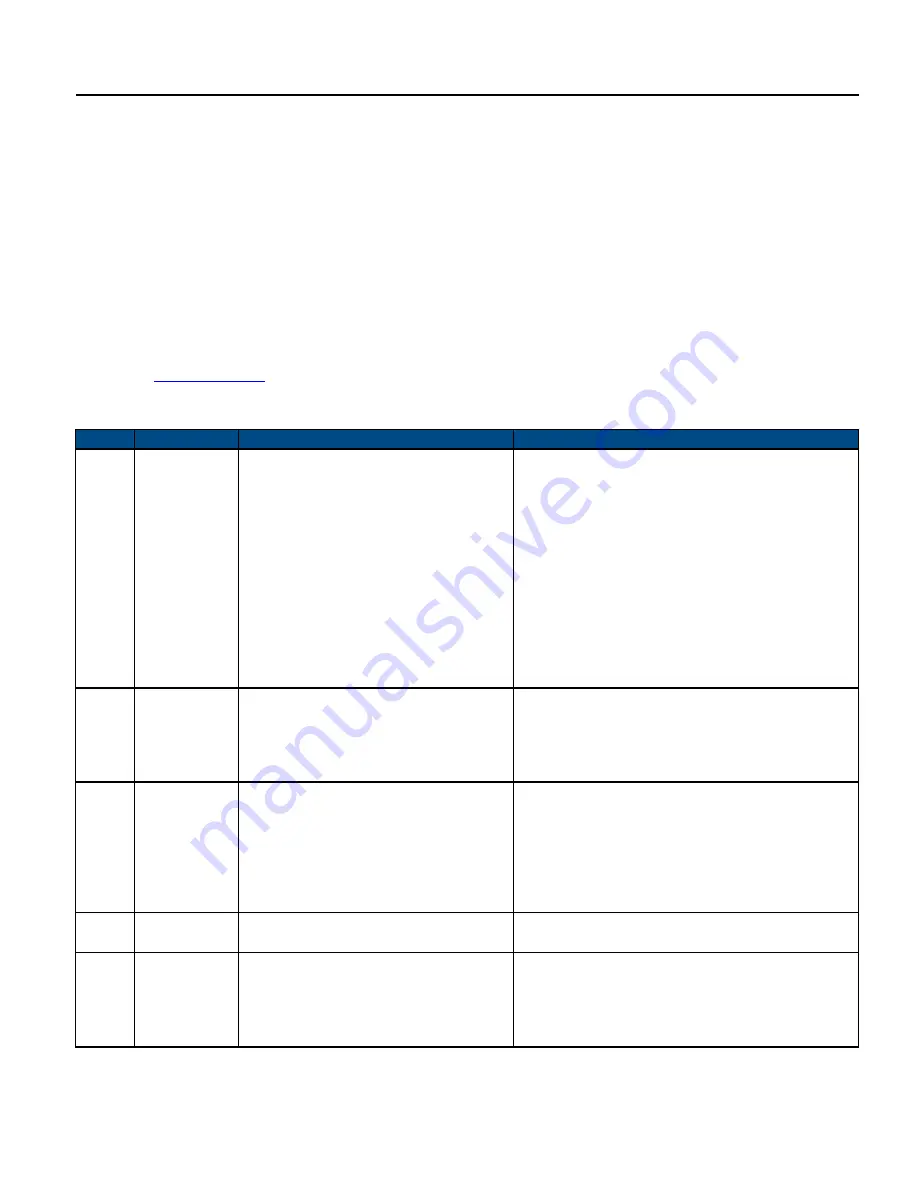

Codes

Fault

Possible Causes

Corrective Action

FF11

Motor

Underload

•

High static, light loading pump

•

Over-pumped well

•

Broken shaft or coupling

•

Blocked screen, worn pump

•

Air/gas locked pump

•

SubDrive not set properly for pump end

•

Frequency near maximum with load less

than configured underload sensitivity

•

System is drawing down to pump inlet

(out of water)

•

Maximum frequency set too low for per-

manent magnet motor

•

Reset Potentiometer for less sensitivity if not out of

water

•

Check pump rotation, reconnect if necessary for

proper rotation

•

If possible, set deeper in well to reduce possibility of

air/gas locked pump

•

Verify DIP switches are set properly

•

Check Underload Sensitivity Setting (Potentiometer

or Wi-Fi)

•

Increase maximum frequency to 125Hz or more for

permanent magnet motors - if maximum frequency

must be below 125Hz, adjust underload sensitivity

setting to a lower value.

FF22

Undervoltage

•

Low line voltage, less than approxi-

mately 150 VAC

•

Miswired input leads

•

Loose connection at breaker or panel

•

Line voltage needs to be 190 to 260 VAC

•

Check incoming power connections and correct or

tighten if necessary

•

Correct incoming voltage. Check circuit breaker or

fuses, contact power company

FF33

Overcurrent or

Locked Pump

•

Motor and/or pump misalignment

•

Dragging motor and/or pump

•

Motor and/or pump locked

•

Abrasives in pump

•

Excess motor cable length

•

Amperage above SFL at 30 Hz

•

Incorrect motor type selected

•

Remove and repair or replace as required

•

Reduce motor cable length. Adhere to Maximum

Motor Cable Length table.

•

Confirm the motor type on DIP SW1 Position 7 is set

correctly.

FF44

Incorrectly

Wired

•

Wrong resistance values on main and

start

•

Check wiring, motor size and DIP switch setting. Ad-

just or repair as needed

FF55

Output Open

Phase

•

Loose connection

•

Defective motor or drop cable

•

Wrong motor

•

Open reading on DC test at start.

•

Check drop cable and motor resistance, tighten out-

put connections, and repair or replace as necessary.

•

Use dry motor to check drive functions. If drive runs

and exhibits an underload fault, drive is good.

Summary of Contents for SubDrive 15

Page 1: ...S SU UB BD DR RIIV VE E C CO ON NN NE EC CT T Owner s Manual ...

Page 14: ...14 ...

Page 22: ...22 ...

Page 30: ...30 ...

Page 36: ...36 ...

Page 40: ...40 ...

Page 56: ...56 ...

Page 62: ......

Page 63: ...ESPAÑOL ES franklinagua com SUBDRIVECONNECT Manual para propietarios ...

Page 70: ...8 ...

Page 78: ...16 ...

Page 84: ...22 ...

Page 88: ...26 ...

Page 96: ...34 ...

Page 102: ...40 ...

Page 106: ...44 ...

Page 128: ......

Page 129: ...franklinwater com FRANÇAIS FR SUBDRIVECONNECT Manuel du propriétaire ...

Page 136: ...8 ...

Page 144: ...16 ...

Page 150: ...22 ...

Page 154: ...26 ...

Page 162: ...34 ...

Page 168: ...40 ...

Page 172: ...44 ...

Page 194: ...REMARQUES ...

Page 195: ...REMARQUES ...

Page 196: ......