10

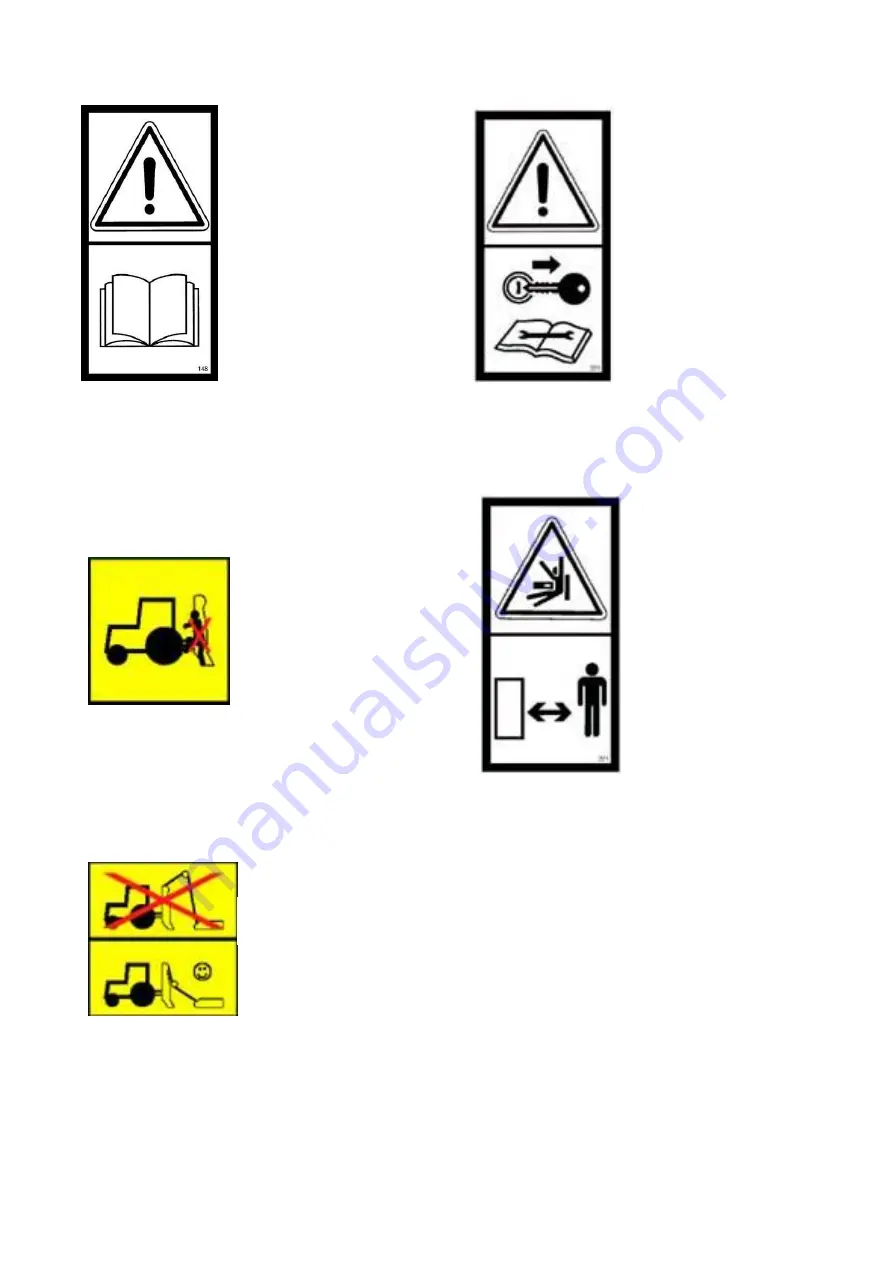

Carefully read operator’s

manual before handling the

machine.

Observe instructions and safety

rules when operating.

D:

Vor Inbetriebnahme die

Betriebsanleitung und

Sicherheitshinweise lesen und

beachten.

Shut off engine and remove key

before performing maintenance or

repair work.

GB:

D:

Vor Wartungs- und

Reparaturarbeiten Motor abstellen

und Schlüssel abziehen.

Stay clear of darft link

lifting range while

operating rockshaft

controls.

Au

ß

erhalb des

Hubbereichs der

Dreipunktaufhängung

bleiben.

Stay clear of swinging area of

machine.

D:

Ausreichend Sicherheits-abstand

zum Schwenkbereich der

Maschine einhalten.

Do not lift only pull

D:

Nicht zum heben nur

Bodenzug.

Summary of Contents for HW-3019

Page 1: ...Fransg rd Manual GB Hydr Forestry Winch HW 3019...

Page 10: ...8 E A B D C D B A Max 30 C...

Page 13: ...11...

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......