15

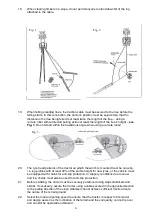

REFILLING OF OIL ON THE MACHINE

The following procedure must be followed closely when refilling oil:

*

Check that the oil tank is completely clean.

*

Always use a filtration device when refilling oil, as the container often contains

fine-grained dust and water.

*

The hydraulic oil is very important and must be selected carefully, as it is the

oil that transfers the energy and also lubricates the various components in

order to minimise friction and heat generation. The oil is also intended to

protect against corrosion and to transport dirt and heat away from the system.

Always use an appropriate mineral oil with the correct additives which is

suitable for this particular machine. Choosing an oil in this way will ensure

trouble-free operation and a long lifetime for both the oil and the components.

Always read the user instructions on the oil packaging from your oil supplier

carefully.

*

Warning:

Contact with hydraulic oil can cause rashes on the skin to

develop in the longer term.

*

The oil’s properties and requirements concerning the supplier of the oil:

The oil must have good lubricating properties on contact with metals at

both low and high RPM.

If possible, the viscosity (consistency) of the oil must remain constant

regardless of the temperature and operating pressure. Always notify the

supplier of the ambient temperature.

The air solubility must be low and air emissions high, whilst the foaming

tendency must be very low.

The corrosion protection properties must be optimal. The oil must be

viscous and therefore also not aggressive or toxic.

When using vegetable oil, we recommend:

CASTROL

:

CARELUBE HTG-32

STATOIL

:

STATOIL M32-68

OK

:

BIOHYDRAUL 32

SHELL

:

NATURELLE HF-M 32

When using vegetable oils, no parts must contain zinc, and synthetic filter inserts

must always be used, as paper inserts can cause problems due to viscosity, resulting

in a high pressure drop.

These oils are used for pump systems which operate at ambient temperatures of

between 5°C and 40°C.

These vegetable oils can all be mixed with mineral hydraulic oils, but this reduces the

lifetime and quality of the oil.

Approx. 4.5 litres of oil are added at the factory. The oil level is approx. 3cm below

the top of the oil tank. Use the dipstick on the plug.

Summary of Contents for W-10014-EH

Page 1: ...Fransg rd Handbook GB W Winch W 10014 EH...

Page 11: ...9...

Page 12: ...10 g A B D E Max 30 Max 30 C A B C D...

Page 13: ...11 G H F...

Page 23: ......

Page 24: ......