Summary of Contents for W-6011-EH

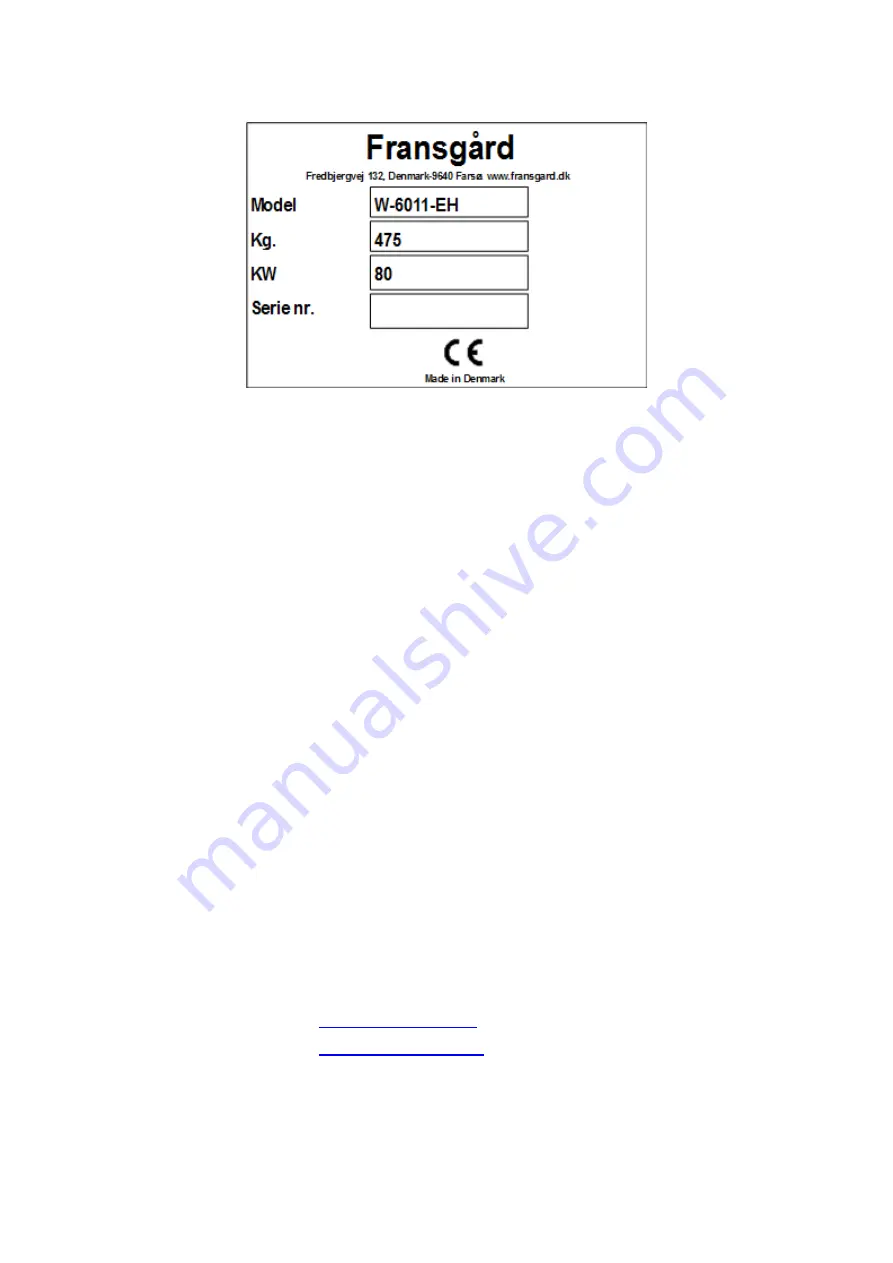

Page 1: ...Fransgård Manual GB Tractor winch W 6011 EH ...

Page 10: ...8 g A B D E Max 30 Max 30 C A B C D ...

Page 11: ...9 F H G Max 4mm ...

Page 13: ...11 ...

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......