Fraser Anti-Static Techniques, Scotts Business Park, Bampton, Devon EX16 9DN, UK

T + 44 (0) 1398 331114 F + 44 (0) 1398 331411 E sales@fraser-antistatic.co.uk W www.fraser-antistatic.com

12

NEOS 30 OEM-DM-Iss.2

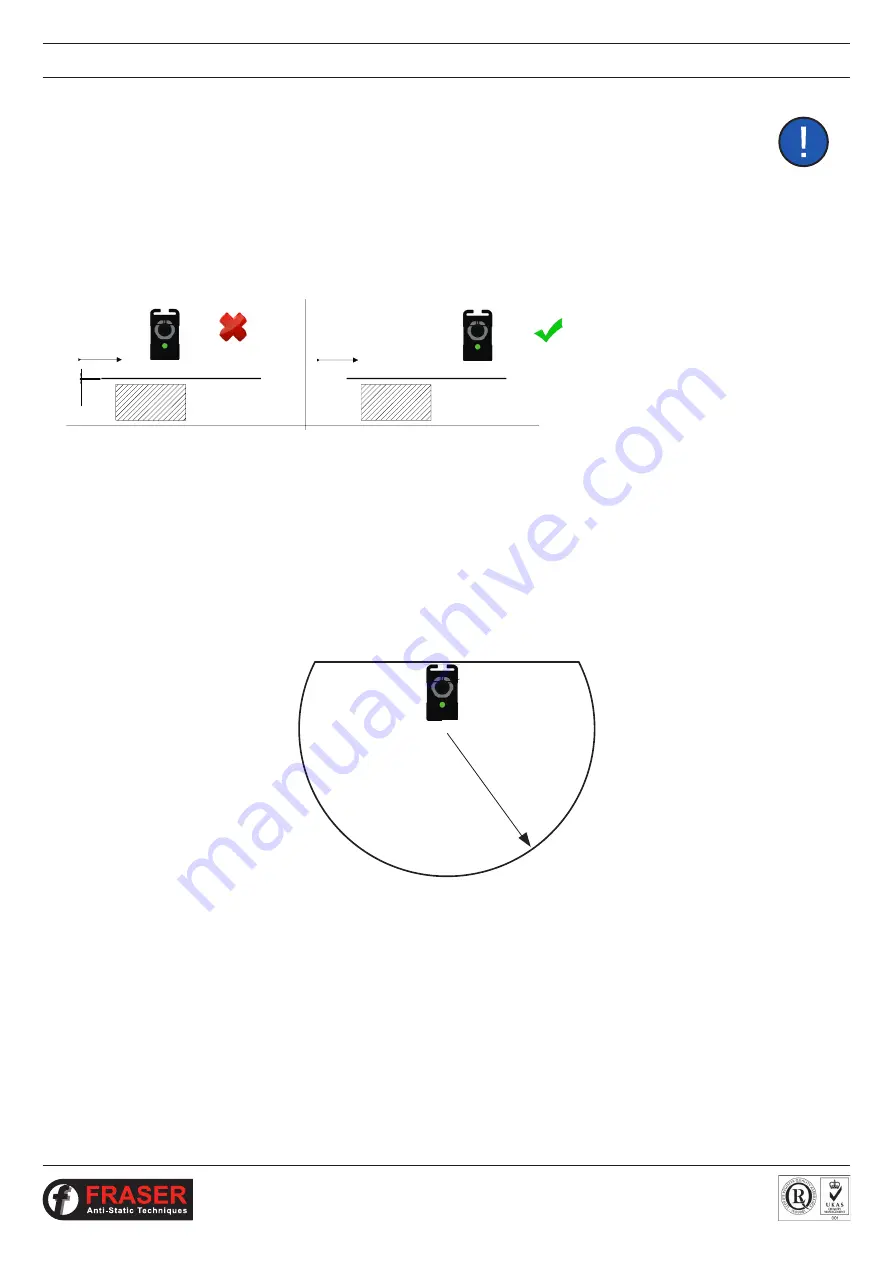

6. POSITIONING

The best location is at, or immediately before, the area where static is causing the problem. Remember that

static can be regenerated if the material passes over rollers or through a process after neutralising. A Static

Meter is useful to determine the best position.

i.

Important: Except on a winding reel of material, the material to be neutralised should be in free air, not

touching another surface as it passes the Bar. It is not possible to neutralise static electricity where the

material is touching another surface or roller.

ii.

The Bars must be dry and oil-free.

iii.

It is important that the emitter pins are not touching, or close to metal objects, to avoid spark erosion that

will damage both the Bar and the metal object.

iv.

The distance from the material should be:

NEOS 30 OEM: 200 - 1500 mm

v.

1.0

R60.0 MIN DISTANCE FROM

ANY EARTHED OBJECTS OR METAL

PLASTIC

PERFORMANCE LEVEL

NEOS 12 F

PERFORMANCE LEVEL

NEOS 12 L

MATERIAL

MATERIAL

FREE AIR

MATERIAL

NO OBJECTS IN THIS AREA

x

x

x

x

MATERIAL

FREE AIR

MATERIAL

R = min. 300 mm

Area to be free of all

ground references

1.0

R60.0 MIN DISTANCE FROM

ANY EARTHED OBJECTS OR METAL

PLASTIC

PERFORMANCE LEVEL

NEOS 12 F

PERFORMANCE LEVEL

NEOS 12 L

MATERIAL

MATERIAL

FREE AIR

MATERIAL

NO OBJECTS IN THIS AREA

x

x

x

x