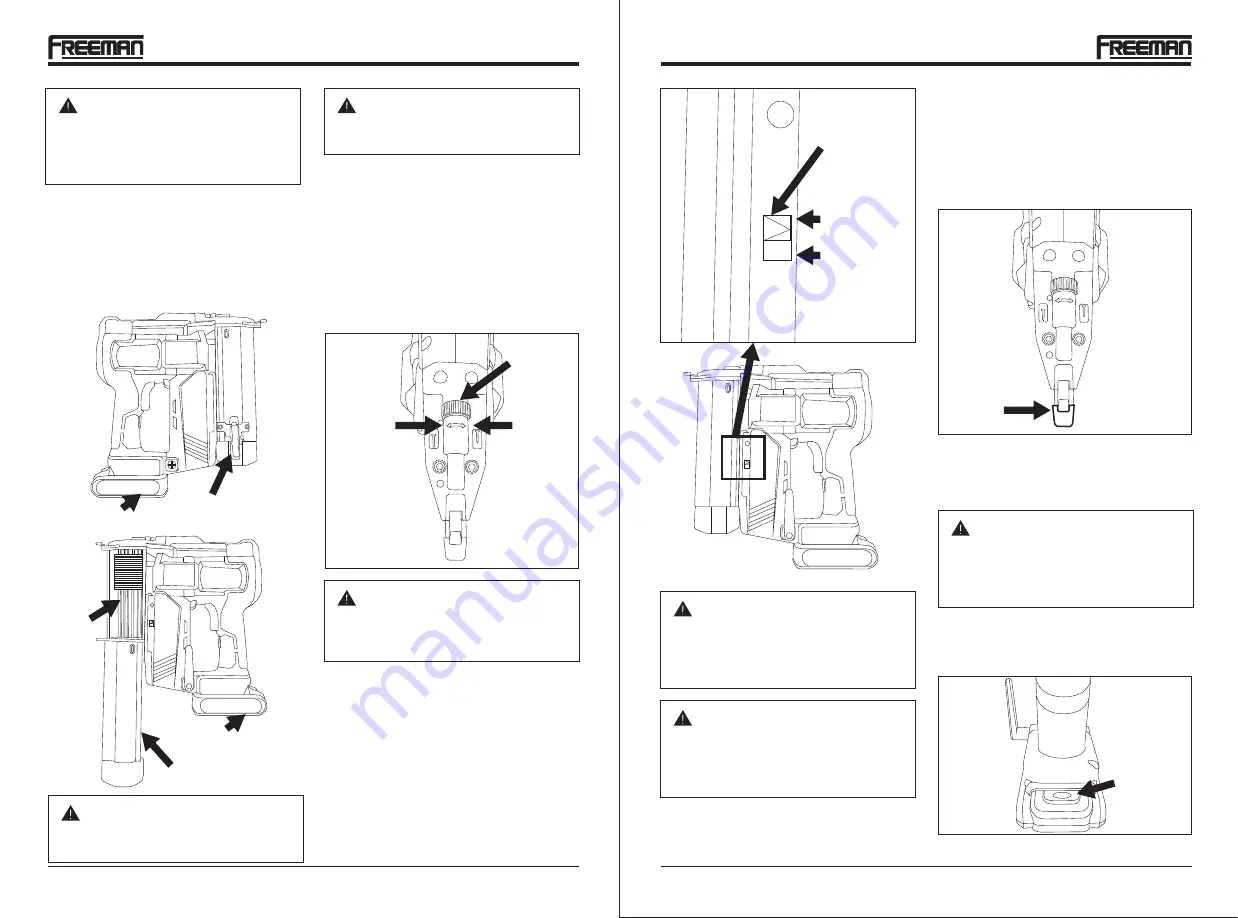

SETTING TOOL FIRING SETTINGS

1.

2.

Fire Selection

Switch

Single Sequential

Firing Position

Bump Fire

Position

DEPTH OF DRIVE

1.

2.

Depth

Adjustment

Wheel (G)

Increase

Depth of

Drive

Decrease

Depth of

Drive

CAUTION:

It is advisable to test the depth of drive

on a scrap workpiece to determine the

required depth for the application.

WARNING:

Always unload all fasteners before

removing the tool from service.

Push the fire selection switch up to select single

sequential fire. This mode requires the trigger to

be pulled each time a fastener is driven. The tool

can be actuated by depressing the work contact

element against the work surface after pulling the

trigger.

Push the fire selection switch down to select bump

fire. This will enable you to fire a shot by holding

down the trigger and pressing the nose of the gun

down on the work piece as many times as is

necessary.

The driving depth of the fasteners is adjustable. To

adjust the depth, use the drive depth adjustment

wheel(G) on the top of the tools nose.

Rotate the depth adjustment wheel in a clockwise

direction when the nose of the tool is pointed away

from you to increase the fastener depth of drive.

Rotate the depth adjustment wheel in a counter-

clockwise direction when the nose of the tool is

pointed away from you to decrease the depth of

drive.

UNLOADING FASTENERS

Remove Battery.

Push down on the latch button(A). Pull back on the

magazine cover(B).

Remove all fasteners from the magazine rail(C).

Push the magazine cover(B) forward until the latch

button pops up.

1.

2.

3.

4.

Latch Button(A)

Magazine Cover(B)

Magazine Rail(C)

Battery

Battery

MODEL: PE2118G

HTTP://WWW.FREEMANTOOLS.COM

1-888-669-5672

09

MODEL: PE2118G

HTTP://WWW.FREEMANTOOLS.COM

1-888-669-5672

08

REMOVING BATTERY

1.

2.

Press battery release button.

Pull battery free of the nailer/stapler body.

Battery

Release

Button

WARNING:

Always know the operational mode of

the tool before use. Failure to know the

operational mode could result in death

or serious personal injury.

WARNING:

An improperly functioning tool must not

be used. Do not actuate the tool unless

the tool is placed firmly against the work

place.

WORK CONTACT ELEMENT

Check the operation of the work contact element trip

mechanism before each use. The WCE must move

freely without binding through its entire travel

distance. The WCE spring must return the WCE to its

fully extended position after being depressed. Do not

operate the tool if the WCE trip mechanism is not

operating properly. Personal injury may occur.

Work

Contact

Element

The no-mar pad attached to the nose of the tool helps

to prevent marring and denting when working with

softer woods.

NO-MAR PAD

WARNING:

Disconnect the tool from the battery

before removing or replacing the no-mar

pad. Failure to do so could result in

serious personal injury.

WARNING:

Always disconnect the power source

before unloading.

WARNING:

Never load fasteners with the workpiece

contact or trigger activated. Doing so

could result in possible serious personal

injury.