8

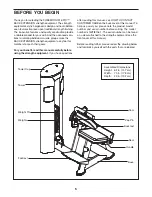

Cable Guards

Check the cable guards to ensure that they are not

rubbing against the cables and that they are holding

the cables in the grooves of the pulleys. If a cable

guard is not correctly aligned, loosen the bolt slightly,

readjust the cable guard as necessary, and retighten

the bolt.

MONTHLY MAINTENANCE

Grips

Check the grips and replace them if needed.

GUIDE ROD LUBRICATION

Clean and lubricate the full length of each guide rod

by wiping it with a soft cloth containing a lightweight

motor oil, 10W-40 or 10W-30 weight. Apply only a

light coating over the entire length of the guide rod.

Do not use TEFLON

®

or silicone-based lubricants.

CABLE ADJUSTMENT

For the strength equipment to function correctly, the

cables must be tensioned correctly. To check the ten-

sion of the cables, insert the weight pin into the top

weight plate. Next, slowly raise and lower the top

weight by performing one repetition. The top weight

should come to rest just on top of the next weight

when the repetition is complete.

If there is too much tension on the cables, the top

weight will not rest on the next weight, and it may be

difficult to insert the weight pin into the weight plates.

If there is not enough tension on the cables, the top

weight will not be lifted immediately when the repeti-

tion is begun. Ideally, the cable should not move more

than 1/2 in. (1.3 cm) from the resting position before

the top weight is lifted.

If there is too much tension or not enough tension on

a cable, adjust the cable as described in the following

steps.

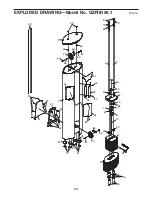

Tower Pulley Adjustment

Tools required: 5/16" hex key, 9/16" open-end wrench

1. Lift the top weight off the

weight stack and insert the

weight pin into the next

weight and the sixth hole

from the top of the weight

rod.

2. Loosen the locknut attach-

ing the pulley to the bracket

in the top of the tower.

3. Move the pulley to the appropriate location in the

bracket. If more slack is needed in the cable,

move the pulley down. If less slack is needed in

the cable, move the pulley up.

4. Make sure that the cable guard is properly orient-

ed (see CABLE GUARDS at the left) and retight-

en the locknut attaching the pulley to the bracket.

5. Lift the top weight and remove the weight pin.

Lower the top weight onto the next weight.

6. Readjust as necessary.

7. Slowly perform a repetition using a light load and

have someone make sure that the cable is not

derailed from a pulley or rubbing on a cable

guard.

Correct Alignment

Incorrect Alignment

Rubbing

Rubbing

Out of

Alignment

Guards

Guards

Cable

Cable

Pulley

Locknut

Summary of Contents for GZFI8156.1

Page 12: ...12 NOTES ...