27

DRIVE TRANSMISSION LUBRICATION

This unit is factory filled and will not normally need

additional lubrication.

Note:

Your

Freerider Companion

transmission is filled with

a special lubricant.

Do not

attempt to force grease into the

transmission as this will contaminate the original lubrication

and will invalidate your guarantee.

Caution:

Take care when lifting the transmission, keep

well away from clothing. It is normal to find a light film

of lubrication around this part.

MOTOR BRAKES

Safety Note:

For your own safety, we recommend that you

check the function of your

Companion

brakes prior to a

journey.

Motor Brake:

If the motor brake is functioning correctly

and the drive is engaged you will not be able to push your

machine when it is switched off. Or switched on with the

speed control lever in the ‘zero speed’, central position.

If your machine can be pushed as described above, the

motor brake could be faulty, or the freewheel system has

been disengaged. Please do not use, contact your local

Freerider distributor.

Note: Check the Freewheeling Instructions on page 9 of

this manual.

Driving Brake: Warning:

When you drive your

Freerider

Companion

and you let go of the speed control lever your

Companion

should reduce speed very quickly. If you notice

a change in the normal slowing/braking condition, and your

Companion

does not slow down quickly,

please do not use

your machine, contact your Freerider distributor.

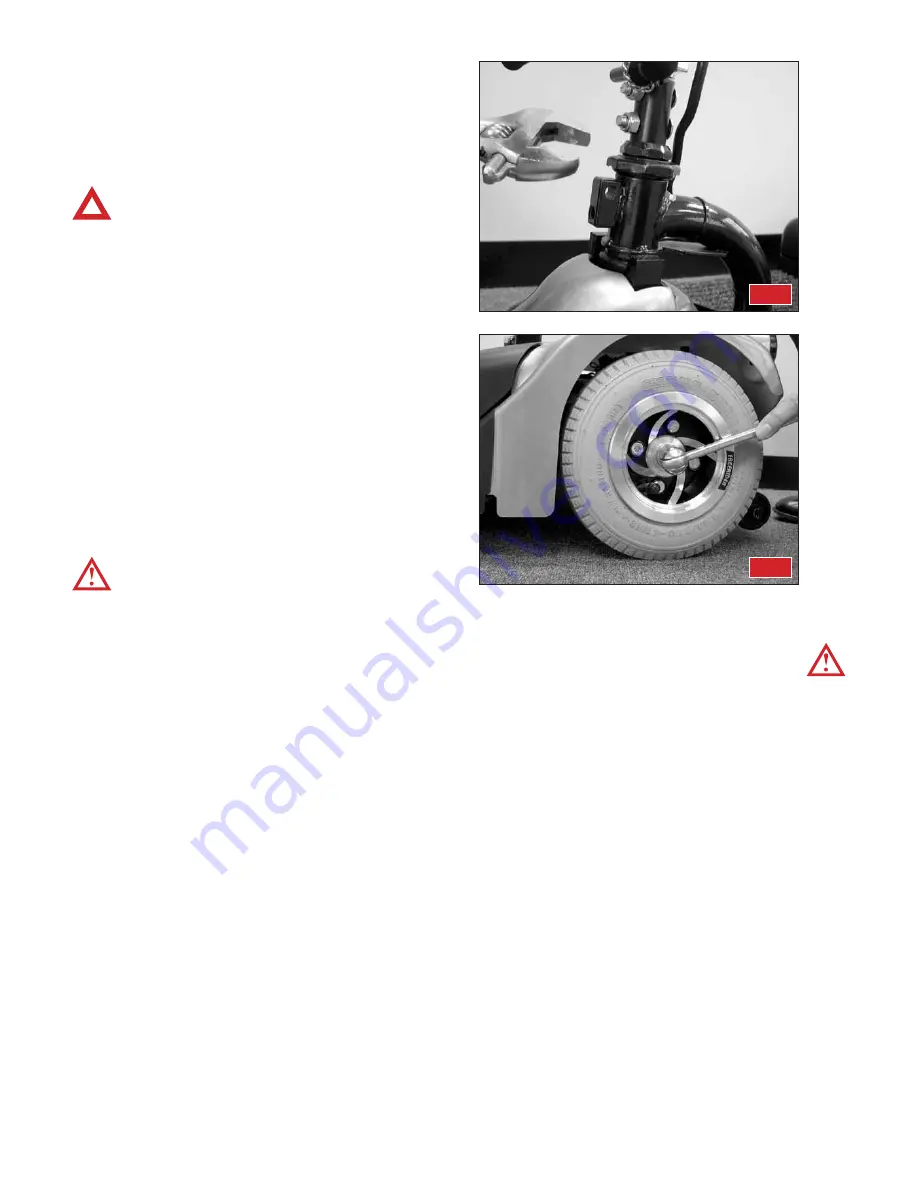

HANDLE BAR BEARINGS

The bearings which control the movement of the steering

handle bar may need to be adjusted if up and down

movement is noticed in your steering handle bars.

The bearings are accessed at the base of your handle

bars.

The bearings are adjusted by first releasing the locking

nut anti-clockwise one full turn with a suitable spanner

(Fig. 36). Turn the upper bearing adjustment nut

clockwise, one flat at a time until all of the up and down

movement in the handle bars is removed. Retighten the

lock nut clockwise into position with a second spanner.

Do not overtighten the bearing adjustment nut, as this

will damage the bearing tracks (fig 36)

The handle bar bearings are NOT ‘Sealed for life’ and

may require lubrication with a general purpose bearing

grease on an annual basis.

TYRES

Check the condition of your tyres regularly. Look for signs

of wear, cuts and foreign objects lodged in the tread.

Maintain the tyre pressures at all times; failure to comply

with this can lead to poor performance of your machine and

could make your machine unsafe and/or unstable.

Warning:

Your Freerider is designed with ‘split’ wheel rims.

Do not

remove wheel bolts with the wheel inflated.

Maintain pneumatic tyres at 30 p.s.i. (210 kpa). Failure to

observe this warning may result in personal injury. Note

low or unequal tyre pressures can make your Companion

become unstable and reduce battery / motor performance.

TYRE SERVICING REAR WHEEL

To remove a rear wheel from your

Freerider Companion

for

the service of a tyre or tube carry out the following

instructions

(only competent people should carry out this

procedure).

1. Switch off your Companion and remove the key.

2. Using a suitable body stand, lift the side of the vehicle

you wish to service off the ground. Place the stand

under the metal chassis. Care must be taken when lifting

heavy loads, you may need a friend to help you. Care

should also be taken when working on a stand.

Please be safe.

Do not lift by the plastic bodywork.

3. With the aid of a 19mm spanner(not supplied) remove

the centre hub nut and washer (see fig 37).

FIG 37

FIG 36