5.

Force lubricant into the upper and lower kingpin

grease fitting caps until new lubricant flows from

between the upper axle beam end and the

knuckle, and between the lower axle beam end

and the knuckle. See

6.

Remove the chocks from the tires.

33–02 Tie Rod End Lubricating

Detroit Axles

For any Detroit axle that requires lubrication of the

tie-rod ends, wipe the grease fittings clean, then

pump multipurpose chassis grease, NLGI Grade 1

(6% 12-hydroxy lithium stearate grease) or NLGI

Grade 2 (8% 12-hydroxy lithium stearate grease),

into the tie-rod ends until all used grease is forced

out and fresh grease is seen at the ball stud neck.

See

Meritor Axles

This procedure applies to all tie rod ends on Meritor

nondrive steering axles.

1.

Park the vehicle with the wheels in the straight-

ahead position. Turn off the engine, apply the

brakes, and chock the rear tires.

2.

Wipe clean the zerk fitting and the seal or boot.

NOTE: Synthetic lubricants are not approved for

tie rod end lubrication.

3.

Using a grease gun, apply a multipurpose

grease, NLGI grade 1 or 2, to the zerk fitting until

all the old grease is purged from the boot. Dis-

colored old grease should come out of the purge

holes near the boot crimp or bellows area.

Apply grease until all the old grease is purged

from the boot.

NOTE: If using an air pressure grease gun, do

not exceed 150 psi (1035 kPa).

4.

If the tie rod end is designed for lube service and

it does not accept grease, perform the following

substeps.

4.1

Remove the zerk fitting.

4.2

Inspect the threaded zerk fitting hole in

the tie rod end, and remove any obstruc-

tions.

4.3

Install a new zerk fitting.

4.4

Apply lubrication to the new zerk fitting.

5.

Remove the chocks from the tires.

33–03 Draw Key Nut Torque

Checking

Axles With Unitized Wheel Ends

Check the torque of the nut that holds the draw key

on the side of the knuckle. The torque should be

30 to 45 lbf·ft (41 to 61 N·m). See

33–04 Tie Rod End Inspecting

IMPORTANT: If the tie rod end boot is torn or

missing, replace the entire tie rod end. Do not

replace the boot only.

1.

Shut off the engine, apply the brakes, and chock

the rear tires.

2.

Check the tie rod boot for cracks, tears, or other

damage. If the tie rod boot is damaged, replace

the entire tie rod end.

3.

The threaded portion of the tie-rod end assembly

must be inserted all the way into the cross-tube

split for adequate clamping. See

. Replace

the components if this cannot be done. For in-

structions, refer to

Group 33

of the

Business

Class® M2 Workshop Manual

.

06/12/2012

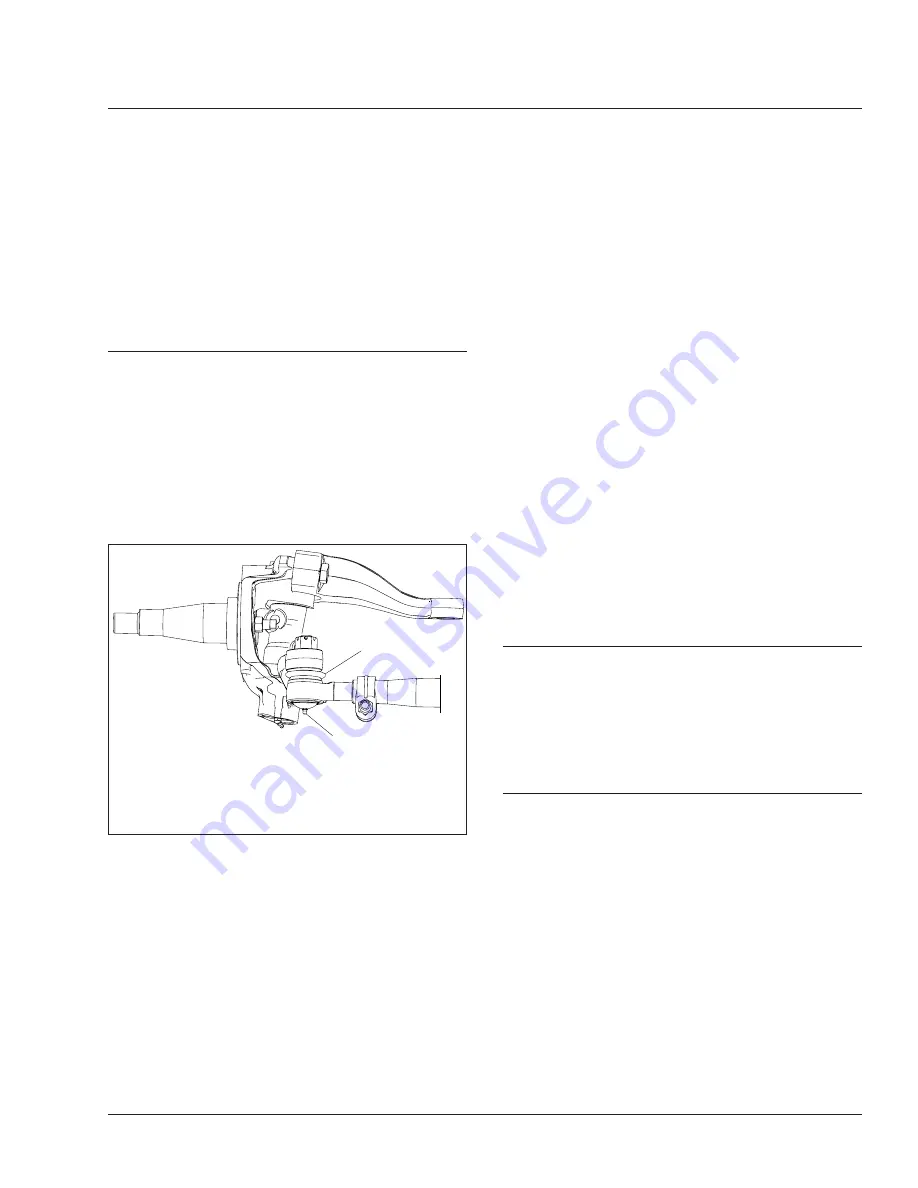

f330273

1

2

NOTE: No grease should emit from the tie-rod boot. If

grease emits from the tie-rod boot, the boot is dam-

aged.

1.

Grease Fitting

2.

Boot

Fig. 5, Grease Fitting and Boot, Detroit Axle

Front Axle

33

Business Class M2 Maintenance Manual, October 2017

33/3

Summary of Contents for BUSINESS CLASS M2 100

Page 2: ......

Page 10: ......

Page 30: ......

Page 34: ......

Page 36: ......

Page 38: ......

Page 40: ......

Page 42: ......

Page 46: ......

Page 52: ......

Page 60: ......

Page 62: ......

Page 76: ......

Page 82: ......

Page 84: ......

Page 94: ......

Page 104: ......

Page 110: ......

Page 112: ......

Page 114: ......

Page 116: ......

Page 120: ......

Page 122: ......

Page 144: ......

Page 146: ......

Page 150: ......

Page 152: ......

Page 166: ......

Page 168: ......

Page 178: ......

Page 180: ......

Page 184: ......

Page 186: ......

Page 188: ......

Page 190: ......

Page 192: ......

Page 196: ......

Page 198: ......