WARNING

Do not use the trailer service brakes for parking;

they are not designed for this purpose. If air

bleeds out of the trailer air tank during parking,

the vehicle could roll, causing serious personal

injury or property damage.

The red octagonal-shaped knob in the control panel

actuates the trailer air supply valve. See

After the vehicle’s air hoses are connected to a

trailer and the pressure in both air systems is at least

65 psi (448 kPa), the trailer air supply valve must be

pushed in. It should stay in to charge the trailer air

supply system and to release the trailer spring

parking brakes.

Pull the trailer air supply valve out before

disconnecting a trailer.

If pressure in both air systems drops to 20 to 45 psi

(138 to 310 kPa), the red trailer air supply valve and

yellow parking brake valve automatically pop out,

applying both the tractor and trailer spring parking

brakes. If the trailer is not equipped with spring

parking brakes, the trailer service brakes are applied.

The yellow diamond-shaped knob in the control

panel actuates the parking brake valve. See

. Pulling out the parking brake valve

applies both the tractor and trailer spring parking

brakes and automatically causes the trailer air supply

valve to pop out. Pushing in the parking brake valve

releases the tractor parking brakes.

NOTICE

Do not use the spring parking brakes if the

service brakes are hot, such as after descending

a steep grade. To do so could damage the

brakes. Allow hot brakes to cool before using the

spring parking brakes.

Do not use the spring parking brakes during

freezing temperatures if the service brakes are

wet. To do so could cause them to freeze. If the

brakes are wet, drive the vehicle in low gear and

lightly apply the brakes to heat and dry them.

If the trailer is not equipped with spring parking

brakes, pulling out the parking brake valve applies

the tractor parking brake and the trailer service

brakes. When the tractor and trailer parking brakes

(or trailer service brakes) are both applied, the trailer

brakes are released by pushing in the trailer air

supply valve, leaving the tractor parking brake

applied. Air pressure in the primary or secondary

reservoir must be at least 65 psi (448 kPa) before

the tractor spring parking brakes, or the trailer

service or spring parking brakes, can be released.

Automatic Slack Adjusters

Automatic slack adjusters should never be manually

adjusted except during routine maintenance of the

foundation brakes (such as replacing shoes), during

slack adjuster installation, or in an emergency

situation.

When the brake pushrod stroke exceeds the legal

brake adjustment limit on a vehicle, there is likely a

mechanical problem with the foundation brake

components or the adjuster is improperly installed.

Visit a repair facility as soon as possible when

brakes equipped with automatic slack adjusters are

determined to be out of adjustment.

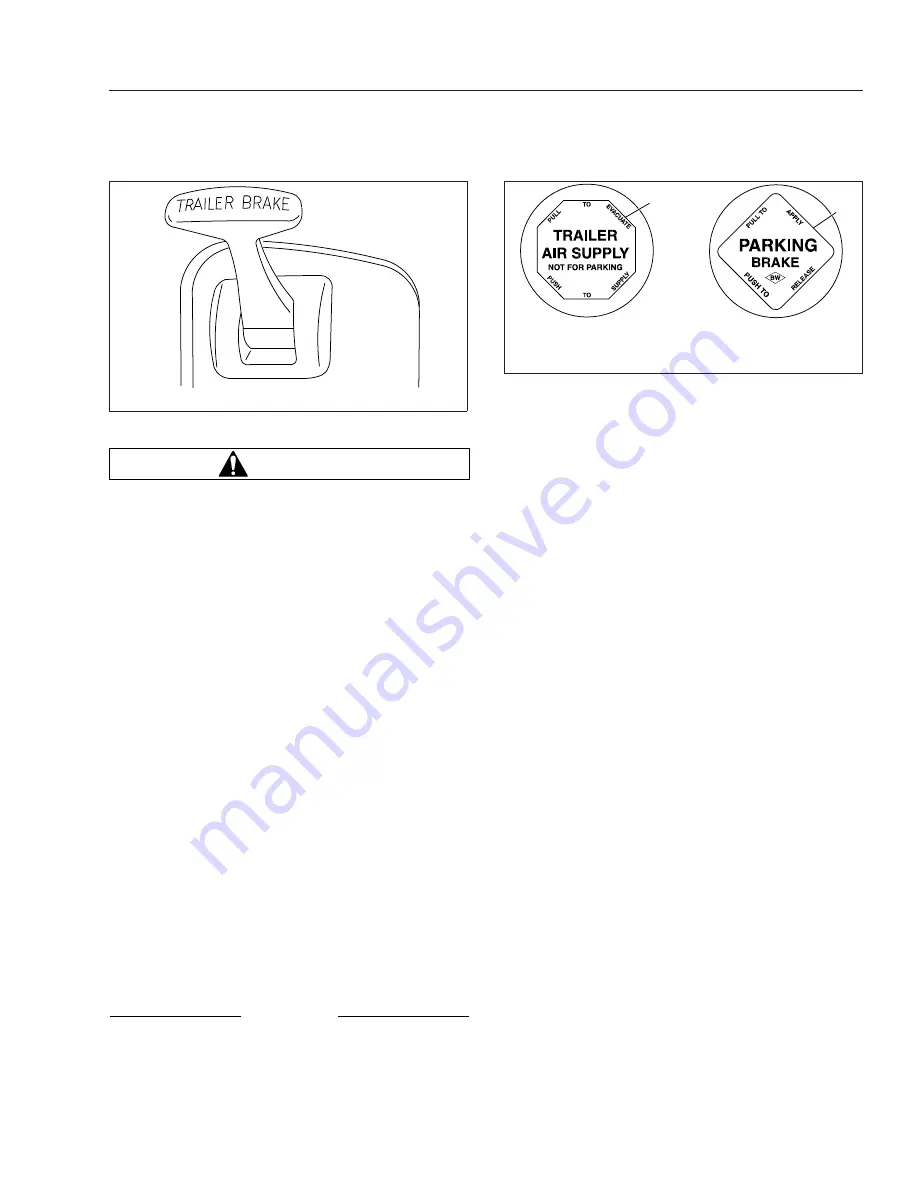

f610591

02/03/2017

Fig. 11.11, Trailer Brake Lever

f610291

02/02/2017

1

2

1.

Trailer Air Supply Valve Knob

2.

Parking Brake Valve Knob

Fig. 11.12, Brake Valve Knobs

Brake Systems

11.6

Summary of Contents for PX113064S T 2016

Page 4: ......

Page 10: ......

Page 18: ......

Page 58: ......

Page 86: ......

Page 112: ......

Page 122: ......

Page 142: ......

Page 154: ......

Page 155: ...12 Steering System Power Steering System 12 1...

Page 158: ......

Page 159: ...13 eAxle eAxle 2 Speed Transmission 13 1...

Page 176: ......

Page 190: ......

Page 202: ......

Page 222: ......

Page 223: ...20 Emissions Information Noise Emissions 20 1 Greenhouse Gas Emissions 20 1...

Page 229: ......

Page 236: ......