Actions

Alarm condition

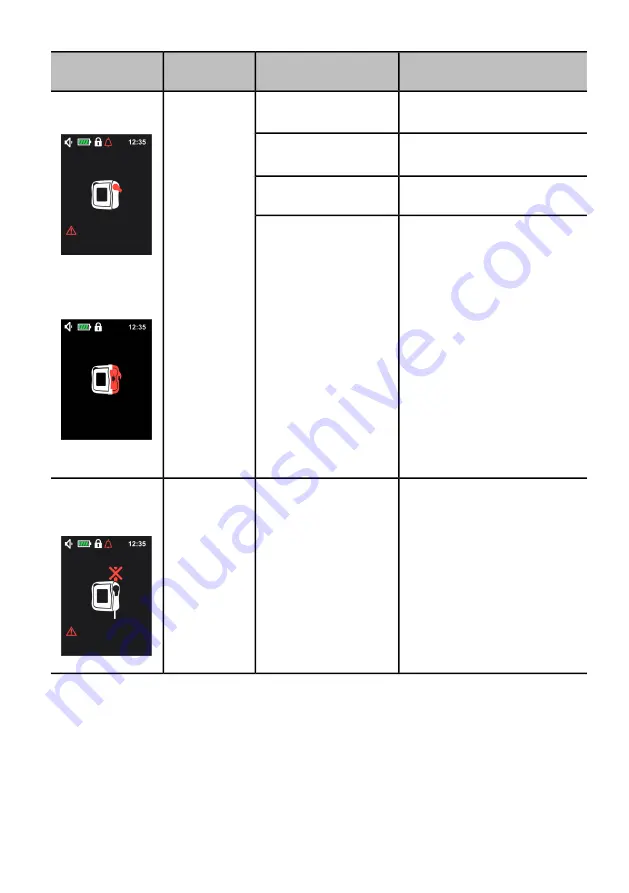

Pumping

status

Symbol

■

Close pump door.

See

on page 27.

Pump door not properly

closed at start.

Pumping stops

Door open

and

appears

alternatively

■

Close pump door.

See

on page 27.

Pump door opened after

start.

■

Re-hang door.

Pump door removed from

its anchoring.

■

Contact your biomedical

department.

Door mechanism is faulty.

■

Open the door, check that the

set is installed properly, close

the door.

See

on page 27.

■

Check that the set is not

kinked.

■

Check that upstream clamp

(pinch clamp, roller clamp) is

open.

■

Check the absence of

upstream / downstream

occlusion in the line.

Upstream flowpath is

blocked between the

container and the pump.

Pumping stops

Upstream

occlusion

81