Electrical Connections

• The extractor fan must be connected to a single

phase mains network, at the voltage and frequency

indicated on the extractor specification plate.

• The installation must have an omnipolar switch

with a contact separation of at least 3mm. The

circuit must be protected by either a 3 Amp fuse

or suitable 3A MCB.

• Earthing is not required as this extractor is a

class II double insulated appliance.

• The extractor must be connected permanently to

by a fixed installation cable secured in fixed

channeling. (Flex of two conductor wires of

minimum section 1mmÇ and maximum 1.5mmÇ).

• The 100 / 125 / 150mm fans have a two speed

motor, the 200mm fans have a three speed motor.

To make the Electrical Connection:

1. Loosen the 4 screws (1. K) and take off the

connection cover (M) (Fig. 2).

2. Perforate the flex holder (O) to allow the

power supply wires to pass through

(Fig. 2 & 3).

3. Make the connections as indicated

on the next page.

C

B

A

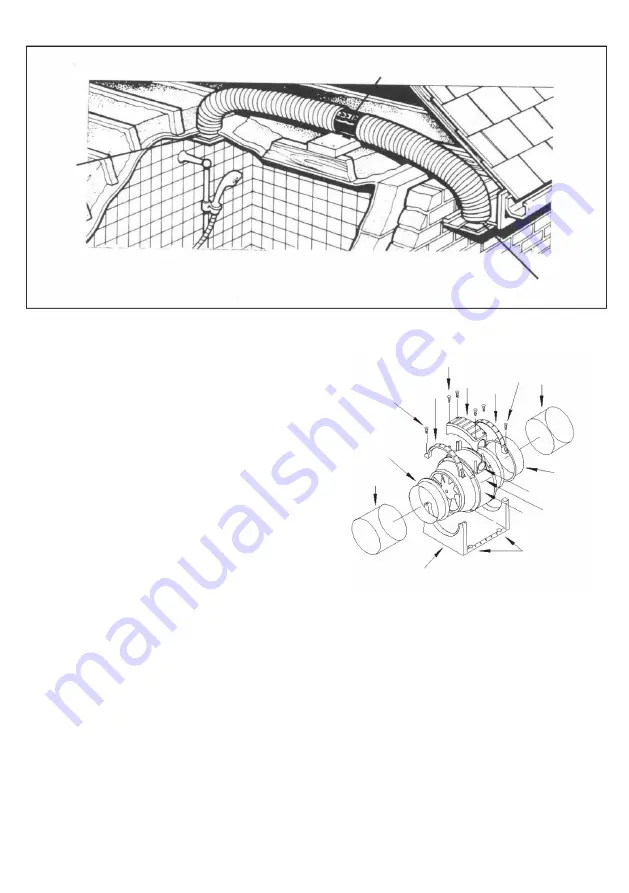

FIG. 1: INSTALLATION DIAGRAM

A

D

E

M

K

E

D

I

B

G

H

F

J

O

I