MCC

–

Cold / Ambient

US

25/40

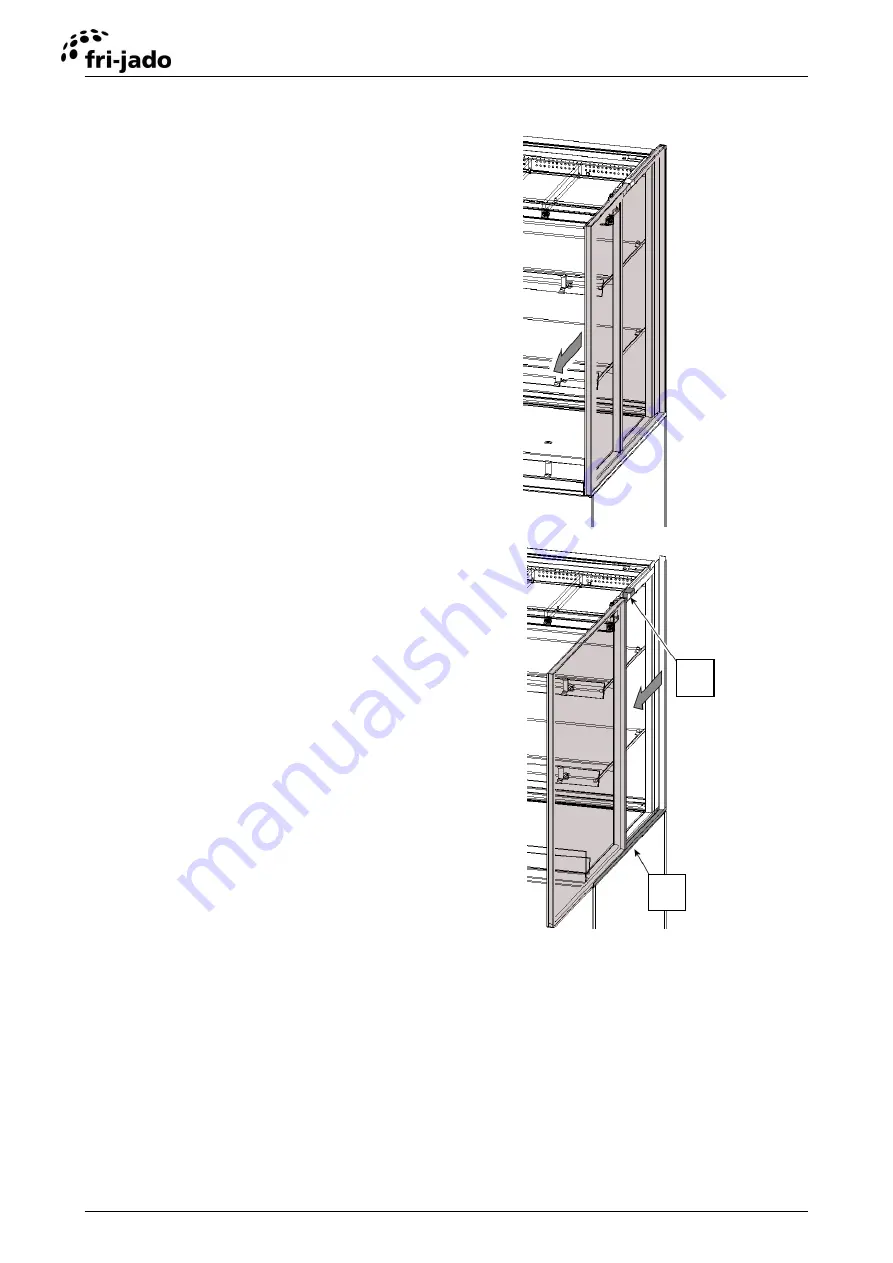

Cleaning the side double-glass pane

•

Slide the double glass pane

towards the front along the top (A)

and bottom (B) guiding rails. The

side pane can be removed from

the unit once it has slid in its

entirety past the top guide.

CAUTION:

Once past the top

guide, the glass pane might fall if

not properly held. Hence do not

leave it standing upright without

being supported by both guide

rails or holding it.

•

It is recommended to only move

the pane to such an extent that the

pane areas next to the support

columns can be cleaned.

•

To clean the guiding rails, the

pane can be removed in its

entirety.

•

If the pane was removed and

needs to be placed back in, before

sliding the pane back into the rails,

ensure the transparent sides of

the pane are facing forwards and

up. Then slide it all the way back

till the front of the pane is in line

with the front plating.

B

A

Summary of Contents for 24-2-A

Page 37: ...MCC Cold Ambient US 37 40 Notes...

Page 38: ...MCC Cold Ambient US 38 40 Notes...