Page 63

Electrical tests

Service Manual Deli Multisserie form 9123560 rev. 02/2017

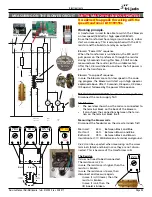

Working principle.

The 3 way valve is turned into the drain (sewer) posi-

tion at the moment that the cleaning program is

started. Waste water goes into the sewer.

As soon as the cleaning program ends or is interrupted,

the valve is turned into opposite direction back to

the default cooking position. Grease wil go down

into the container.

The cooking position is activated by output X3 on the

slave I/O board. (relay in OFF position)

As soon as the cooking position is reached, the contact

inside the motor housing disconnects the motor and

activates relay K7.

The contact of relay K7 closes and connects terminal

X30 to X31 on the Pwr and I/O board. This is the

feed back signal for the processor that the valve

reached the cooking position

The cleaning position is activated by output X4 on the

slave I/O board. (relay ON). When in position, the

motor contact activates relay K8, the contact of K8

closes and connects terminal X16 to X17.

A 7-core cable provides the power and the signal wires

for the 3 way valve.

Note that wire nr 2 is not used. It has been cut out the

cable. The terminal block inside the motor housing

has the same numbers as the wires inside the cable.

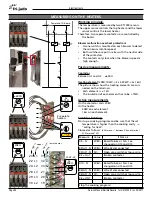

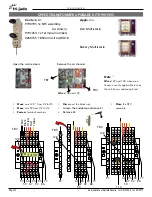

Passive measurements

(resistance)

Disconnect the mains supply first!

The picture overview shows which measurements can

be expected without disconnecting wires.

Disconnect wire “1” from the terminalblock (TB2-1) for

further measurements!

The 3 way valve in cooking position.

(normal position)

Between 1 and 3

∞

Ω

Between 1 and 4

5000 Ω (Motor of valve)

Between 3 and 4

∞

Ω

Between 3 and 5

± 0 Ω (Feed back signal)

Between 4 and 6

∞

Ω

The 3 way valve in cleaning position.

Between 1 and 3

5000 Ω (Motor of valve)

Between 1 and 4

∞

Ω

Between 3 and 4

∞

Ω

Between 3 and 5

∞

Ω

Between 4 and 6

± 0 Ω (Feed back signal)

The 3w. valve in between cooking and cleaning pos.

Between 1 and 3

5000-6000 Ω (Motor of valve)

Between 1 and 4

5000-6000 Ω (Motor of valve)

Between 3 and 4

1000-1200

Ω (Motor of valve)

Between 3 and 5

∞

Ω

Between 4 and 6

∞

Ω

Note that the resistances of the motor can reach 6000Ω

and 1200 Ω after a run. The motor is thermally

protected.

X30

X31

X17

X16

11

14

21

24

K7

K8

54

53

98

95

drain

cooking

pos.

pos.

cleaning

drain

5V

Power and I/O board

MEASURING ON THE 3 WAY VALVE

X4

X3

drain valve

cooking

pos.

cleaning

pos.

M4

50

48

36

A2

A1

4

3

A2

K8

1

K7

5

6

A1

107

101

101

TB2-1

TB2-2

TB2-3

Slave board

X10

38

39

X11

N

L

40

X3

X4

50

48

X16

X17

X30

X31

54

53

98

95

1 3 4

5

6

PE

101

107

54

53

95

98

101

36 48 50

Note that wire

nr. 3 is on terminal 2

and wire

nr 4 on terminal 3!!!

K7 K8

TB2

± 5kΩ

± 5kΩ

50-200Ω

± 36kΩ

± 0 Ω

± 36kΩ

± 36kΩ

± 0 Ω

Cooking position->

Cleaning position->

± 36kΩ

Cooking position->

Cleaning position->

Typical resistance

values without dis-

connecting wires!