Page 66

Electrical tests

Service Manual Deli Multisserie form 9123560 rev. 02/2017

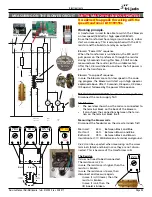

X10

X9

A1

A1

A2

A2

3

3

1

1

K6

K3

41

42

58

44

56

X14

37

40

X15

N

L

Power and I/O board

Working principle.

The temperature is measured by two PT1000 sensors.

The upper sensor controls the top heater and the lower

sensor controls the lower heater.

Therefore, two separate contacters are controlled by

the board.

Blower malfunction overheat protection!

• A vane switch is mounted on each blower to detect

the minimum rotationspeed.

• Both switches are put in series with the neutral side

of the contactors.

• The contacts only close when the blowers speed is

high enough.

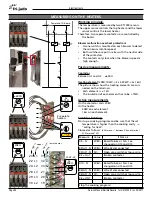

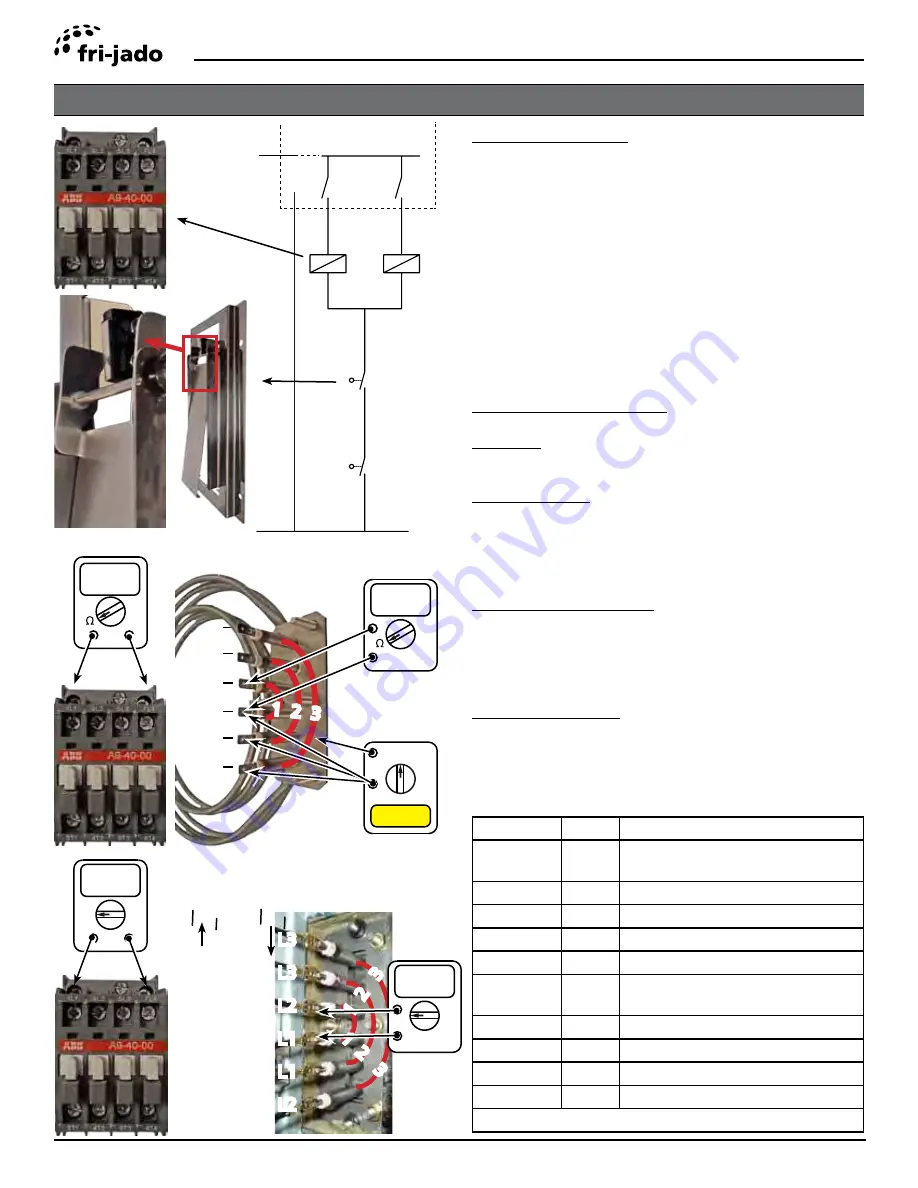

Passive measurements.

Contactor

Between A1 and A2

±600Ω

Heating element

(208V, 10kW -> 3x 3,33kW -> 3x 16A)

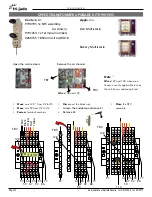

The picture shows how the heating elements are con-

nected on the terminals.

• Each element is ± 13Ω

• The insulation of each element has to be >1MΩ.

Active measurements

On the contactor coils 208V

On the heater:

208V on each element.

16A on each element.

Trouble shooting.

Start up a cooking program and be sure that the set

temperature is higher than the cooking cavity -->

“asking for heat”.

Proceed as follows:

(X9-N means “between X9 and terminal

X15 (marked “N”)

MEASURING ON THE HEATERS

500V

!

Insulation test

>1MΩ

±600Ω

1 2 3

1 2 3

V~

3x

208V~

1 2 3

3x

± 13Ω

3 separate

heaters

L3

L3

L2

L1

L1

L2

V~

208V~

Measure

Value

If Not ok

X9 - N

208V~ Board failure or N & L ex-

changed on X14 and X15.

K3(A1) - N 208V~ Wire 42 disconnected

K3(A2) - N 0V~

Open vane switch or loose wire.

K3 = On?

Broken contacter

X10 - N

208V~ Board failure or N & L ex-

changed on X14 and X15.

K6(A1) - N 208V~ Wire 41 disconnected

K6(A2) - N 0V~

Open vane switch or loose wire.

K6 = ON?

Broken contacter

Stop the cooking program!

L1-L2-L3

L1

L1

L2

L3

L3

L2

23

22

24

28

29

30

upper

31

32

33

21

20

19

lower heater

Wire nr

.

Phase

Wire nr

.

Phase