210.100-IOM (JUL 2018)

Page 13

ACUAIR

®

HYGIENIC AIR UNITS

INSTALLATION

REASSEMBLY PROCEDURE FOR SPLIT UNIT

PERFORMANCE SERIES ONLY

1. Position sections on level surface.

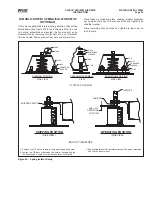

2. Apply polyurethane caulk in two parallel continuous beads

on both faces as indicated in Figures 9, 10 and 11.

3. Attach hand winches to either side of the base via relocated

lifting lugs and pull the sections together. Bolt base per Figure 9.

ASSEMBLY HINT

It may be advantageous to locate the first section in

it's final position and attach it to the support structure

before pulling the next section into position.

4. Install the reconnect flange attachment hardware starting

from the middle of the bottom angle working around to the

middle of the top angle, making use of a drift pin to align the

holes. Bar clamps may be needed to align the roofs together.

If bar clamps are needed, use wood for protection in between

the bar clamp and unit.

5. Split seams that have internal access to both sides of

split will be reattached with bolts and nuts. Split seams with

internal access to only one side of split will have cage nuts

on the blind side and bolts installed from accessible side. All

bolt holes require a bolt.

6. If bolt holes do not align, it may be due to racking during

transit to job site. Use jack to lift one side until holes on the

wall of the opposite side align. Bolt this wall together and

then remove jack from opposite side. As the unit settles, the

out-of-square racking caused during transit should realign.

7.

Once the sections are drawn together and the reconnect flanges

are aligned and attached, apply two parallel beads of caulk along

either side of the reconnect seam on the exterior of the AcuAir unit

as shown in

Figure 13.

8. Install the shipping split covers as shown in Figure 13 using

the #10 TEK screws and washers provided. Apply a fine bead

of caulk to either edge of the split cover and allow time to dry.

9. Once the shipping cover is in place and the caulk has had

time to set, apply the roof coating as shown in Figure 14.

10. INSPECT all splits to see if polyurethane caulk was applied

and split was bolted properly.

11. Reconnect all electrical conduit and wiring at the

reconnect junction boxes. Use electrical conduit sealing putty

to seal all conduit openings into and out of the junction box to

prevent the migration of moisture. (reference the information

on page 42)

12. INSPECT all splits to see if all electrical and piping

connections are complete and correct.

NOTICE

Temporary roof supports and diagonal (shipping) sup

-

ports should not be removed until the split sections are

completely reassembled.

See Page 18 for Food Grade and

Sanitary Connections!

INTERNAL RECONNECT

(AcuAir Performance Series Only)

.75 FLAT WASHER

.75 HEX BOLT

(USE FROM LIFTING LUG)

.75 HEX NUT

(USE FROM LIFTING LUG)

.75 SPLIT WASHER

.75 FLAT WASHER

.25 MINIMUM DIA. PARALLEL CONTINUOUS BEADS OF

POLYURETHANE CAULKING REQ’D (BOTH FACES OF SPLIT)

PRIOR TO REASSEMBLING

RECONNECT, HOUSING, AND

HARDWARE NOT SHOWN THIS SIDE

FOR CLARITY

HOUSING

Figure 9 – Base Assembly Attachment - Relates to AcuAir Performance Series Unit Only

PERFORMANCE GRADE CONNECTIONS

Summary of Contents for AcuAir

Page 54: ......