210.100-IOM (JUL 2018)

Page 38

ACUAIR

®

HYGIENIC AIR UNITS

OPERATION

Examine your environment. If structure, equipment, or other

elements of your facility show rust or corrosive effects, the

evaporator coils are not likely to be impervious to the same

effects of the environment. Consider this when formulating

your maintenance program.

GAS HEAT START-UP

1. Close the manual gas shutoff valve external to the burner.

2. Turn off the electrical power to the furnace.

3. Set the temperature to the lowest possible setting.

4. Set the burner controls to the OFF position.

5. Wait five minutes to clear out any gas. Then smell for gas,

including near the floor.

6. Set the burner controls to the ON position.

7. Close the door on the front of the gas manifold.

8. Open the manual gas valve external to the furnace.

9. Turn on the electrical power supply to the furnace.

10. Set the controls to the desired temperature.

NOTICE

This heater is equipped with an ignition device which

automatically lights the burner. Do not try to light the

burner by hand.

NOTICE

There is an approximate 30 second delay between

controls energizing and burner firing.

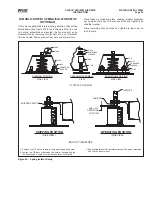

Figure 45 - AcuAir Direct Fired Gas Burner

GAS HEAT SHUTDOWN

1. Set the controls to lowest setting.

2. Turn off the electrical power supply to the furnace.

3. Set the burner controls to the OFF position.

4. Close the manual gas shutoff valve external to the furnace.

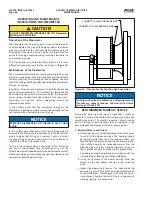

Figure 46 - AcuAir Gas Burner Wrapper

24-Hour Run-In

After 24 hours of operation under load, the following services

should be performed:

1. Examine the unit for any unusual noise or vibration.

2. Readjust fan belt tension if required.

START-UP AFTER PROLONGED SHUTDOWN

It is imperative that maintenance personnel conduct a

thorough start-up before running the unit after a prolonged

shutdown.

At minimum, the following checks must be preformed:

1. Clean any debris from guards, fans, eliminators, heat

transfer coils, and filters.

2. Turn the fan(s) by hand to ensure rotation without

obstruction.

3. Verify and, if necessary, adjust the fan belt tension. (See

Belt Replacement and Tensioning

section)

4. Prior to start-up, lubricate the fan shaft and motor

bearings. The ball bearings are factory lubricated, but should

be relubricated if the unit has been sitting on site for more

than a year before start-up.

5. Check the locking collar on each fan shaft bearing and

tighten if necessary.

6. Verify the voltage and current of all three legs of the fan

motors. The current should not exceed the rated service factor.

After prolonged shutdowns, the motor insulation should be

checked with a Megger Tester prior to restarting the motors.

7. Start the fan(s) and verify proper rotation as indicated by

sticker on unit.

Summary of Contents for AcuAir

Page 54: ......