190.210-IOM (SEP 21)

Page 7

LazerWeld II Plate Heat Exchanger

Installation

Installation

Before installing

NOTICE

Before start-up, check that all tightening bolts are

firmly tightened and that you use the correct mea

-

surements of the plate pack. See LWZWII drawing

and

section.

• To avoid water hammer, do not use fast-closing valves.

• Install safety valves according to current pressure ves-

sel regulations.

• If the LZWII surface temperature is expected to be hot

or cold, insulate the heat exchanger.

• Use protective sheets to cover the plate pack.

• For each model, design pressures and temperatures are

marked on the identification plate. These must not be

exceeded.

• Full vacuum conditions apply at start up for refrig-

eration duties to avoid moisture and air in the heat

exchanger.

Requirements

Space

A minimum free space is needed for lifting cassettes in

and out. Refer to the delivered drawing.

Foundation

Install on a flat foundation giving enough support to the

frame.

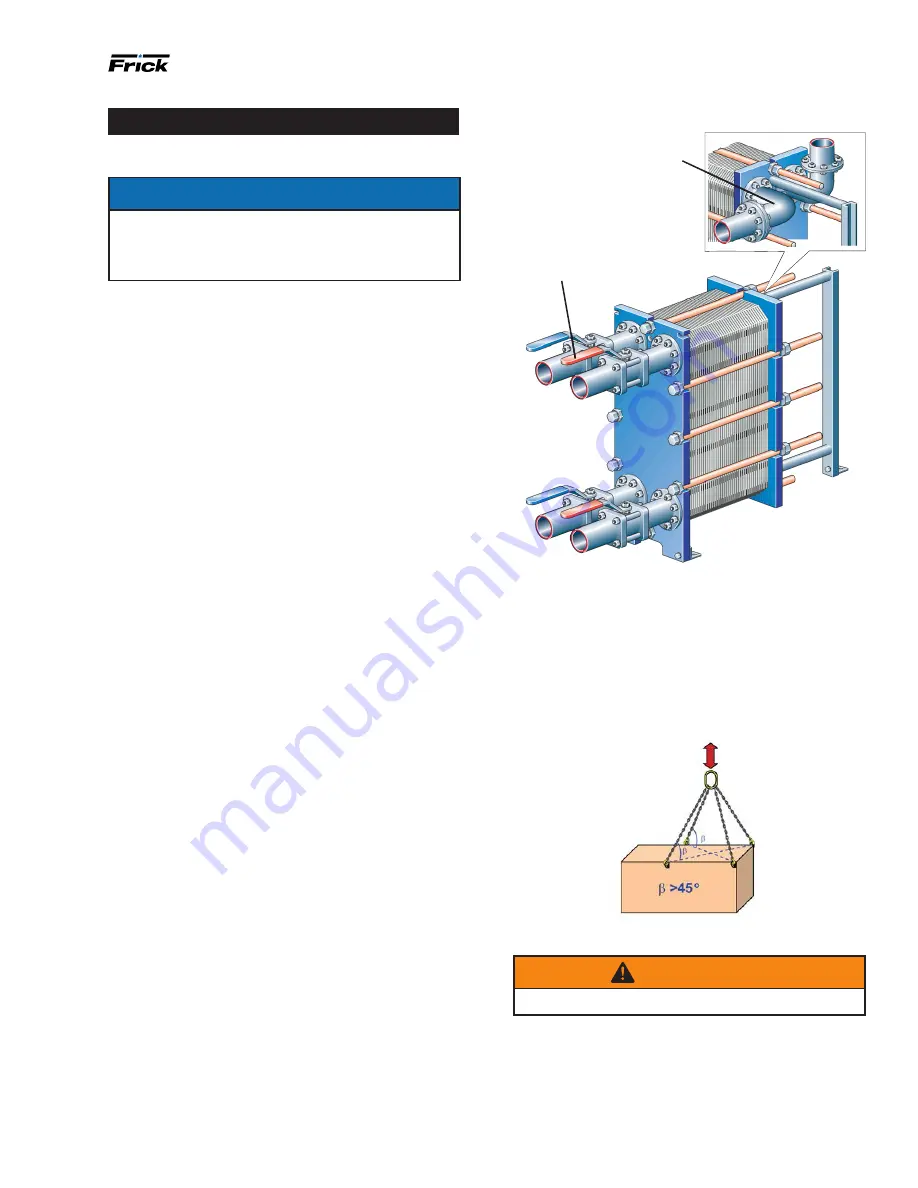

Elbow

To allow easier disconnection of the LZWII, connect an el-

bow to the pressure plate using a flange, directed upwards

or sideways, and with another flange located just outside

the contour of the heat exchanger.

Shut-off valve

In order to open the LZWII, install shut-off valves at all

connections.

Connections in the pressure plate

Ensure the plate pack is tightened to the correct dimen-

sion A before connecting the pipe system. Verify on the

nameplate.

Drip tray (optional)

Depending on the type of fluid in the LZWII and the type of

installation, a drip tray (drainage box) may be necessary to

avoid injury to personnel and damage to equipment.

Note:

Put the drip tray in place before positioning the LZWII

Figure 5: Shut-off valve and elbow location

Lifting

Use straps when lifting the LZWII. Attach the straps as

illustrated in

with a minimum angle of 45°.

Position straps as illustrated in

Figure 6: Lifting straps

WARNING

Never lift by the connectors or studs.

Shut-off valve

Elbow