190.210-IOM (SEP 21)

Page 11

LazerWeld II Plate Heat Exchanger

Operation

Operation

Starting the unit

During start-up, check that no visible leakages appear

from the plate pack, valves, or piping system.

NOTICE

If several pumps are included in the system, ensure

you know which one to activate first.

NOTICE

Make adjustments of flow rates slowly in order to

avoid the risk of pressure surge (water hammer).

Water hammer is a short-lasting pressure peak that

can appear during start-up, or shut-down of a sys-

tem, causing liquids to travel along a pipe as a wave

at the speed of sound. This can cause considerable

damage to the equipment.

NOTICE

Charging liquid ammonia into a refrigeration circuit

under vacuum results in low temperatures. Such

temperature levels might be lower than any elasto-

meric materials can seal against.

In applications where the field side is used for a two

-

phase refrigerant, for example cascade CO

2

/NH

3

ap-

plications, it is very important to fill the two-phase

refrigerant in gas phase. This to avoid temperature

chocks for the gaskets and to avoid temporary leak-

ages due to the natural fact that the metal is shrink-

ing very fast.

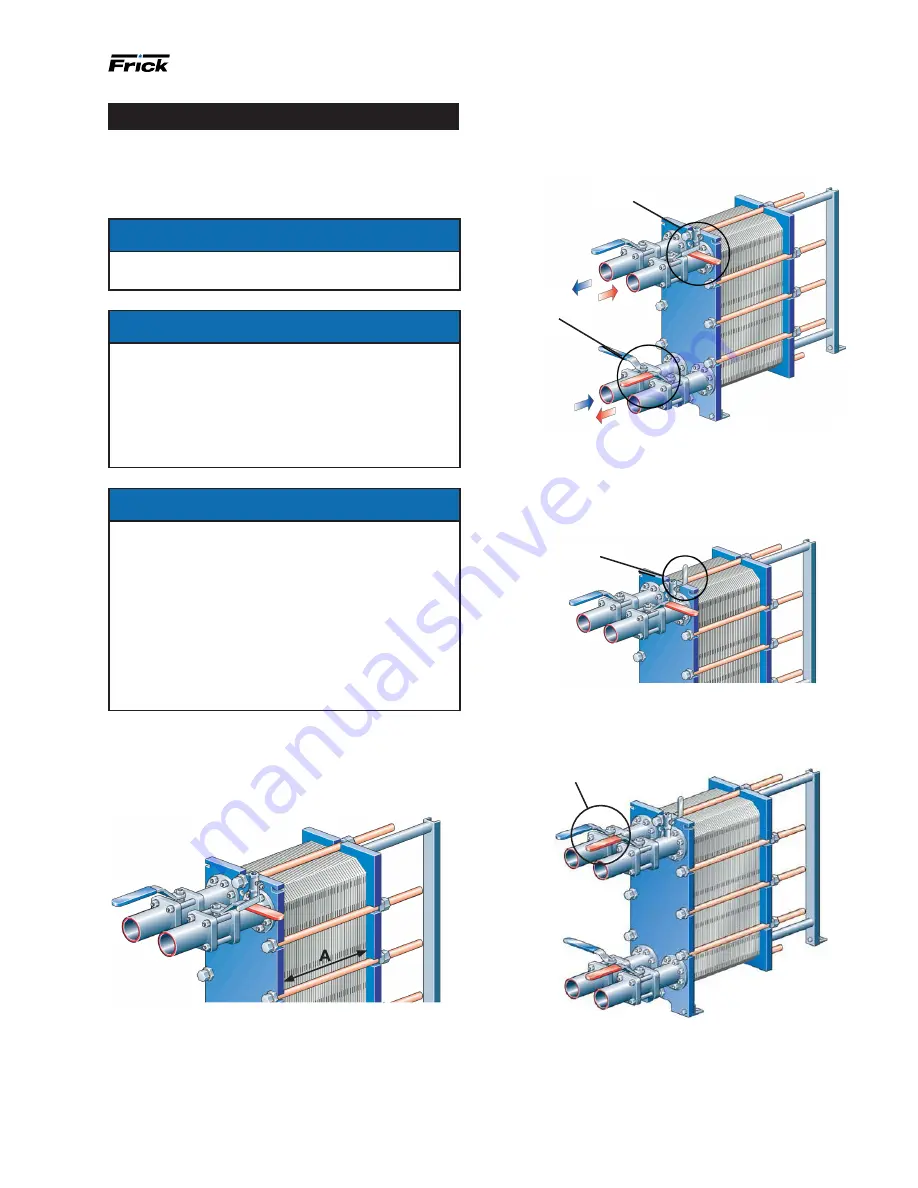

1. Before start-up, check that all tightening bolts are

firmly tightened and that the dimension A is correct.

See the following figure.

Figure 17: LZWII, dimension A

2. Check that the valve is closed between the pump and

the unit controlling the system flow rate.

Figure 18: Valve positions

3. If there is a valve at the exit, make sure it is fully open.

4. Open the air vent and start the pump.

Figure 19: Open the air vent

5. Open the valve slowly.

Figure 20: Open the valve to pump

Valve

Open

Closed

Open