VYPER

™

VARIABLE SPEED DRIVE

INSTALLATION

100-200 IOM (FEB 09)

Page 12

INTERFERENCE WITH ElECTRONIC

EQUIPMENT

RFI / EMI are acronyms for Radio Frequency Interference

and Electro Magnetic Interference. Any electronic device

which switches currents at high speed is capable of generat-

ing RFI and EMI. Some typical sources are computers, light

dimmers, and motor speed controls. RFI refers to electrical

fields, which are transmitted through the air. EMI refers to

electrical currents, which are conducted in wiring connected

to the device.

The Vyper

™

generates both RFI and EMI. Most RFI energy

generated by Vyper

™

is contained within it’s cabinet. The EMI

energy is conducted back in to the power line, and may be

capable of causing interference to other electronic equipment

that is powered by the same electrical distribution system.

VSDs are used successfully in many installations, which uti-

lize sensitive electronic equipment. However, in some highly

sensitive cases, there may be electronic equipment that is

affected by Vyper

™

originated EMI. For those cases, an op-

tional Harmonic Filter is recommended to reduce conducted

EMI levels by reducing current harmonics to limits defined by

the IEEE 519-1992 standard. The filter is located within the

Vyper

™

cabinet and is factory installed and tested. The filter

can also be retrofitted to an existing Vyper

™

.

The IEEE 519 filter is required on all hospital applications, and

is strongly recommended for any installation with sensitive

electronic equipment connected to the electrical distribution

system. The filter is also required whenever a local utility

places a limit on current distortion for an electronic device.

The IEEE 519 harmonic filter is filter is required where total

harmonic current distortion must be 8% or less.

SYSTEM OPERATING CONDITIONS

Refrigeration systems considered for Vyper

™

application

must be in good operating condition. A site survey should be

completed with the help of a trained Frick service technician.

The technician will review the condition of the equipment and

recommend actions that must be taken to ensure that the

equipment is in good operating condition. This survey must

be taken and required repairs made prior to the application

of the Vyper

™

.

PNEUMATIC CONTROlS

Pneumatic controls must be replaced with electronic controls

to be compatible with the Vyper

™

and the Quantum LX

™

control panel.

VYPER

™

SYSTEM OVERVIEW

The Frick Vyper

™

Variable Speed Drive is a liquid-cooled,

transistorized, PWM inverter in a highly integrated package.

This unit is factory designed to mount either remotely on a

stand or integrally to the compressor package. The power

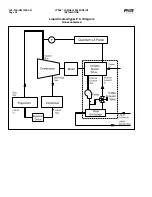

section of the drive is composed of four major blocks:

• AC to DC rectifier section with integrated

precharge circuit

• DC link filter section

• Three-phase DC to AC inverter section

• Output suppression network

An electronic circuit breaker with ground fault sensing con-

nects the AC line to an AC line choke and then to the DC

converter. The line choke will limit the amount of fault current

so that the electronic circuit breaker is sufficient for protecting

the Vyper

™

input fuses. (See schematic, Figure 8)

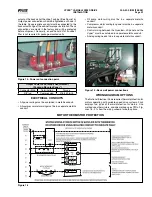

THE AC TO DC SEMI-CONVERTER

uses 3 Silicon Con-

trolled Rectifiers (SCRs) and 3 diodes. One SCR and one

diode are contained in each module. Three modules are

required to covert the three-phase input AC voltage to DC

voltage (1SCR-3SCR). The modules are mounted on a liquid-

cooled heatsink. The use of the SCRs in the semiconverter

configuration permits precharge of the DC filter link capacitors

when the chiller enters the prelube cycle. It also provides fast

disconnect from the AC line. The SCR trigger board provides

the turn on and turn off commands for the SCRs. The Vyper

™

logic board provides commands to the SCR trigger board

during precharge.

THE DC lINK FIlTER SECTION

of the drive consists of a

series of electrolytic filter capacitors (C1-C6). These capaci-

tors provide a large energy reservoir for use by the DC to

AC inverter section of the Vyper

™

. The capacitors are con-

tained in the Vyper

™

Power Unit. “Bleeder” resistors (RES1

and RES2) are mounted on the side of the Power Unit to

provide a discharge of the DC Link filter capacitors after

power is removed.

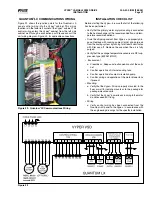

THE DC TO AC INVERTER SECTION

of Vyper

™

serves

to convert the DC voltage back to AC voltage at the proper

magnitude and frequency as commanded by the Logic

board. The inverter section is composed of one power unit.

This power unit is composed of very fast switching transis-

tors known as an Insulated Gate Bipolar Transistor (IGBT)

module (1MOD) mounted on the same liquid-cooled heatsink

as the semiconverter modules, the DC Link filter capacitors

(C1-C6), a semiconverter, and a Vyper

™

Gate Driver board.

This board provides the turn on, and turn off commands

to the IGBT’s output transistors. The Vyper

™

Compressor

Drive Logic board determines when the turn on, and turn off

commands should occur. The gate driver board is mounted

directly on top of the IGBT module, and it is held in place with

mounting screws and soldered to the module. This improves

reliability by eliminating the gate wires and their possible

failure. In order to minimize the parasitic inductance between

the IGBT module and the capacitor bank, copper plates which

electrically connect the capacitors to one another and the

IGBT modules are connected together using a “laminated

bus” structure. This “laminated bus” structure forms a parasitic

capacitor which acts as a low valued capacitor, effectively

canceling the parasitic conductance of the copper plates. To

further cancel parasitic inductances, a series of small film

capacitors (C7-C9) are connected between the positive and

negative plates at the IGBT module.

THE VYPER

™

OUTPUT SUPPRESSION NETWORK

is

composed of a series of capacitors (C10-C12) and resistors

(3RES-8RES). The job of the suppressor network is to reduce

the time it takes for the output voltage to switch as seen by

the motor. It also limits the peak voltage applied to the mo-

tor windings, as well as the rate of change of motor voltage.

These are problems commonly associated with PWM motor

drives such as stator winding end turn failures and electrical

fluting of motor bearings.

Other sensors and boards are used to convey information

back to the Vyper

™

and provide safe operation of the variable

speed drive. The IGBT transistor module contains a thermis-

tor temperature sensor that provides temperature information

back to the logic board via the gate driver board. The AC to

DC semiconverter heat sink temperature is also monitored

using a thermistor temperature sensor (RT2). The uses the

three resistors on the board to provide a safe impedance