VYPER

™

VARIABLE SPEED DRIVE

INSTALLATION

100-200 IOM (FEB 09)

Page 8

The Vyper

™

can be used at altitudes up to 10,000 ft without

derating for units without the IEEE 519 Harmonic Filter. A

Vyper

™

with the Harmonic Filter included can be operated up

to 5,000 ft without derating. Due to less dense air at higher

altitudes, the maximum entering condenser water tempera-

ture, or supply cooling water, must be reduced as shown in

the following table.

Altitude

MAX Entering

Water Temp

Vyper Coolant

Control Setpoint

0 ft

100.0°F / 37.8°C

110°F / 43.3°C

5,000 ft

95.6°F / 35.5°C

105°F / 40.5°C

10,000 ft

89.6°F / 32.0°C

100°F / 37.8°C

15,000 ft

82.3°F / 27.9°C

95°F / 35.0°C

Remotely mounted units must have the distance limited

between the Vyper

™

and the compressor motor to 50 feet

of wire or less. The problems that may be encountered with

wire lengths greater than 50 are as follows;

• VSD picks up interference in the control wiring, causing

the VSD to intermittently trip.

• Voltage drop becomes excessive, rising above the 5%

voltage drop limit.

•

Peak voltage applied to the motor windings becomes

excessive and may cause premature motor failure.

• A

dV/dt filter must be installed on remote-mounted units

with motor power lead lengths between 3 to 50 feet.

Adequate service clearances, including door swing, must

be maintained around the Vyper

™

. Care should be taken to

ensure that the Vyper

™

and it’s associated piping and wiring,

do not obstruct the access to service areas.

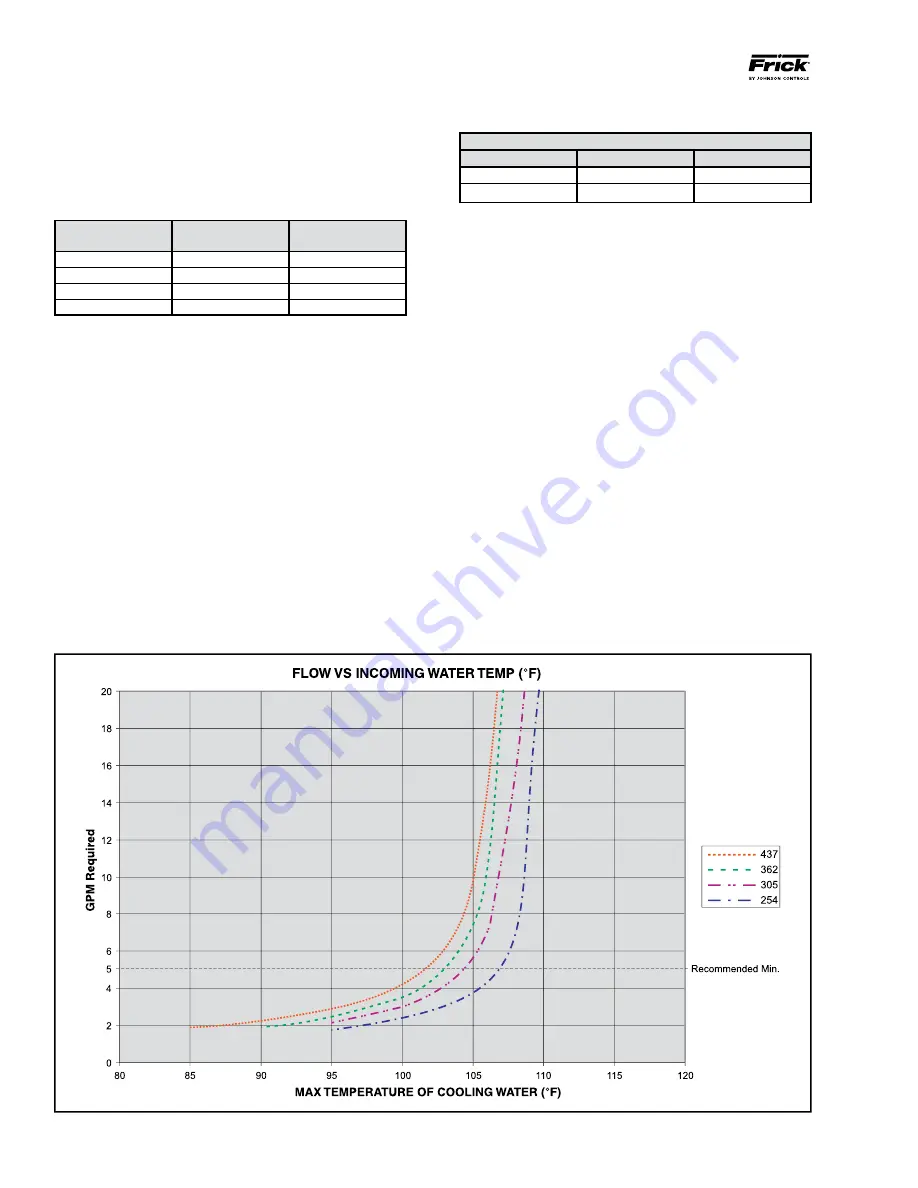

Liquid supply cooling temperature requirements vary between

Water and Glycol cooled units. The required flow rate is based

on the maximum temperature of the coolant to be used.

COOlANT TEMPERATURE lIMITS

Entering Coolant Temperature limits (Deg F)

Min

Max

Water

40

105

Glycol

35

105

General Coolant Requirements

• Vyper

™

Liquid-cooled models provide 1½ NPT threaded

connections IN and OUT of the Heat Exchanger.

• An upstream strainer is recommended to stop particulate

matter from entering the heat exchanger. The strainer

should be cleaned several times during the first twenty-four

hours of operation.

• Sufficient clearance to perform normal service and main

-

tenance work should be provided around the entire unit.

• Flow rates are as shown in the chart in Figure 2.

Water Recommendations

• Johnson Controls-Frick recommends a closed-loop system

for the water side of the heat exchanger.

• We recommend a water pH level between 6.0 and 7.4 for

proper heat exchanger life.

NOTE: To reduce the potential of fouling the heat ex-

changer, recommended minimum flow rate is 5 GPM.

Glycol Recommendations

•

Propylene Glycol is to be used exclusively. Glycol concen-

tration must be 50% or less by volume.

Figure 2 - Flow Rates