S70-101SM

Page 3

Frick XJS and XJF Rotary Screw Compressor

Service Manual

GENERAL

This manual provides approved procedures for teardown,

parts replacement, and rebuild of Model XJS and XJF 95/120

compressors, manufactured by Frick and installed on RXB

and RXF Rotary Screw Compressor Units.

To avoid errors when ordering parts, always provide complete

Model Number and Serial Number.

MODEL AND SERIAL NUMBER EXPLANATION

MODEL NUMBER

ROTOR DIA. (MM)

2.13/1 GEAR RATIO – S

1.31/1 GEAR RATIO – M

1.62/1 GEAR RATIO – L

SERIAL NUMBER

A - 95S

B - 95M

C - 95L

D - 120S

E - 120M

F - 120L

GENERAL MAINTENANCE

Proper maintenance is important in order to ensure continued, trouble-

free service from your compressor. Some areas critical to optimum

compressor operation are:

• Keep refrigerant and oil clean and dry to avoid moisture contamination.

After servicing any portion of the refrigeration system, evacuate to

remove moisture before returning to service. Water vapor condensing

in the compressor while it is running, or more likely while it is shut down,

can cause rusting of critical components and reduce the service life of

the unit.

• Keep suction strainer clean. Check periodically, particularly on new

systems where welding slag or pipe scale could find its way into the

compressor suction. Excessive dirt in the suction strainer could cause

it to collapse, dumping debris into the compressor.

• Keep oil filters clean. If filters show increasing pressure drop

(indicating dirt or water), stop compressor and change filters. Running

a compressor for long periods with high filter pressure drop can cause

oil starvation and lead to premature bearing failure.

• Avoid slugging compressor with liquid refrigerant. While screw-type

compressors are probably the most tolerant to ingestion of some

refrigerant liquid, they are not liquid pumps. Be sure to maintain

adequate superheat, and properly size suction accumulators to avoid

dumping liquid refrigerant into compressor suction.

• Keep liquid injection valves properly adjusted and in good condition

to avoid flooding compressor with liquid. Liquid can cause a reduction

in compressor life, and in extreme cases, can cause complete failure.

XJS 95/120 S 0123 D

• Protect compressor during extended periods of shutdown. If

compressor will be setting for long periods without running,it

is advisable to evacuate to low pressure and charge with dry

nitrogen or oil, particularly on systems known to contain

amounts of water vapor.

• Preventive maintenance inspection is recommended any

time a compressor exhibits a noticeable change in vibration

level, noise level, and/or performance.

NOTE: • Some photographs or illustrations in this manual

may be of prototype or special order units. Pro-

duction models may vary in some detail from

those shown.

• Some photographs or illustrations in this manual

may show units with optional equipment installed.

These items are available through your autho-

rized Frick Factor.

PREVENTIVE MAINTENANCE INSPECTION AND

SERVICE

Frick Model XJS and XJF 95/120 Rotary Screw Compressors

are designed and manufactured to the highest engineering and

quality standards to provide optimum performance and con-

tinued service in applications of intended use, with no devia-

tions from original design. A preventive maintenance pro-

gram ensures maximum compressor life and minimizes costly

unscheduled unit downtime. Immediate shutdown and in-

spection should be made if increased sound or vibration,

increased shaft seal leakage, erratic slide valve operation,

fluctuating oil pressure, loss of compressor efficiency, in-

creased oil consumption, and/or oil contamination are ob-

served. Major inspection should be made, per the schedule,

listed in the Frick Rotary Screw Compressor IOM manual.

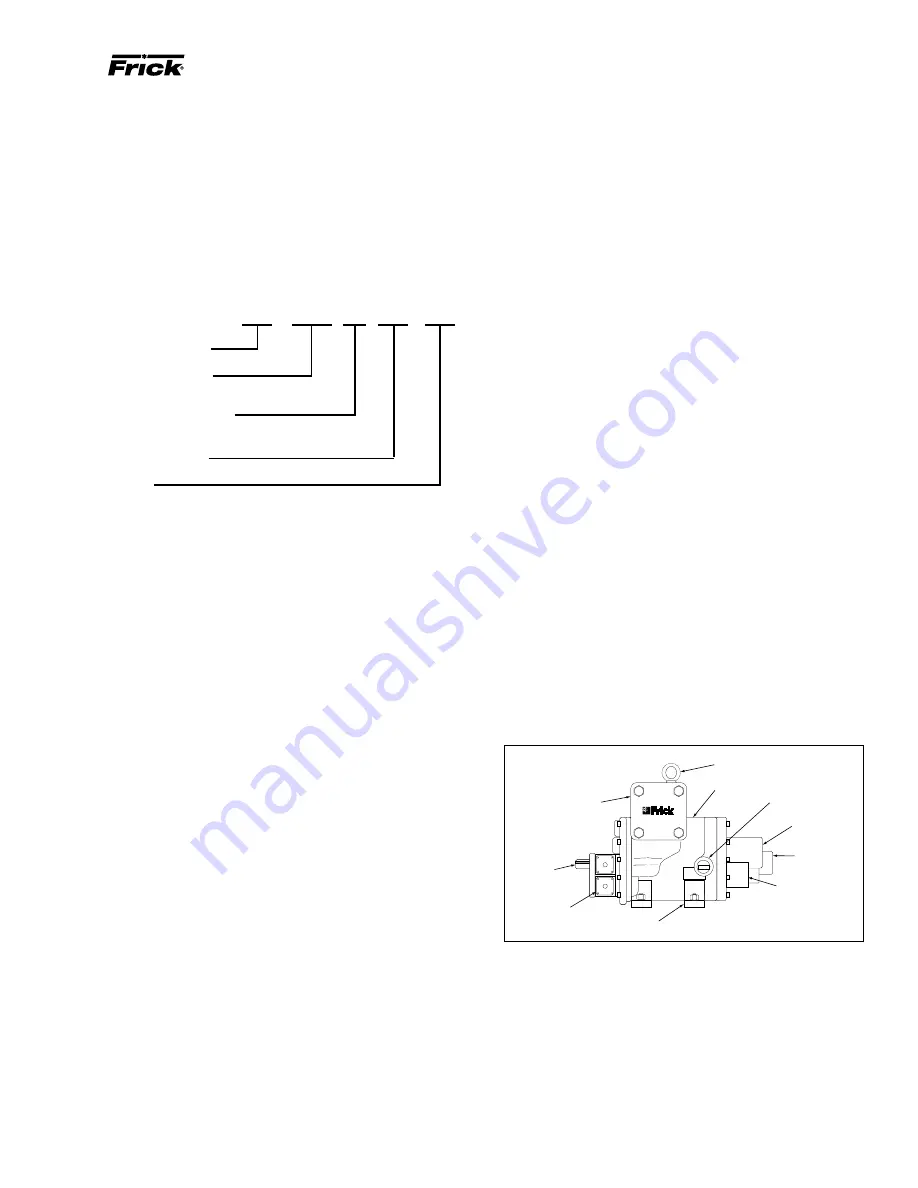

XJS and XJF Rotary Screw Compressor

DRIVE

END

Vi CONTROL SOLENOID

VALVE (120 VAC)

DRIVESHAFT

FRONT VIEW

MOUNTING

FOOT (4)

SUCTION VALVE

AND

STRAINER ASSY.

SLIDE VALVE

INDICATOR

SLIDE VALVE

ASSY.

ROTOR

CASING

LIFTING EYE

GEAR AND ROTOR

ASSY.

DISCHARGE

END

ECONOMIZER PORT

Property of American Airlines