S70-101SM

Page 7

Frick XJS and XJF Rotary Screw Compressor

Service Manual

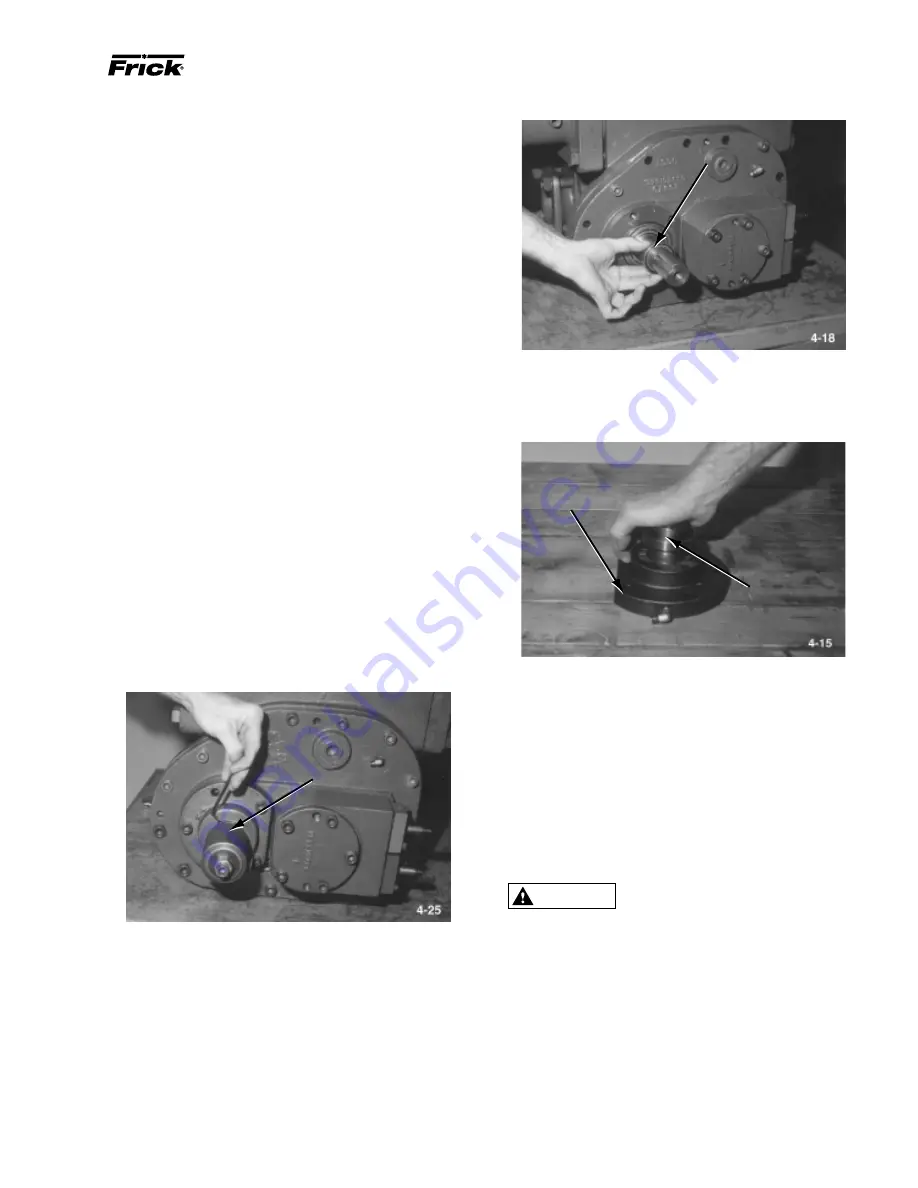

SEAL SEAT

8. Place seal housing (4) on workbench with inboard side

facing down; using Seal Installation and Removal Tool, push

(with hand pressure only) carbon-faced seal assembly out

of housing.

SEAL HOUSING

SEAL REMOVAL

AND INSTALLATION

TOOL

1.0.2 COMPRESSOR – ASSEMBLY. Compressor assem-

bly shall be accomplished in the following order:

1. Compressor Suction Strainer Cleaning and Installation

(Refer to paragraph 1.5.2).

2. Rotors and Bearings – Installation (Refer to paragraph 1.4.2).

3. Slide Valve and Stop – Installation (Refer to paragraph 1.3.2).

4. Jackshaft and Gears – Installation (Refer to paragraph 1.2.2).

1.1.1 SHAFT SEAL REPLACEMENT. This procedure

provides the information necessary for qualified personnel to

replace the jackshaft carbon-faced seal, including required

compressor disassembly.

1.1.2 SHAFT SEAL – REMOVAL. Shaft seal removal shall

be accomplished as follows:

NOTE: Index numbers refer to Figure 1-2, unless other-

wise noted.

1. Evacuate compressor and oil separator (refer to S70-101

IOM).

2. Remove flexible drive coupling (refer to S70-101 IOM).

3. Loosen oil supply line nuts at elbows (2, Figure 1-1), which

are located on seal housing and gear cover.

4. Loosen hex-head screw in clamp collar (2); remove clamp

collar and seal seat backup ring (3) from jackshaft (1).

5. Remove capscrews (7) securing seal housing (4) to gear

cover (52). Remove seal housing and seal housing o-ring (8).

A small amount of oil will drain from housing.

NOTE: Provisions should be made to catch residual

oil that will drain when seal housing is removed.

6. Remove seal housing oil supply tubing (3, Figure 1-1).

7. Remove rotating seal seat portion (Figure 1-1) of shaft seal

assembly (6) from jackshaft (1).

CLAMP COLLAR

9. Remove carbon-faced seal assembly o-ring (5) from seal

housing.

10. Remove oil supply line elbow (2, Figure 1-1) from seal

housing.

1.1.3 SHAFT SEAL – INSTALLATION. Shaft seal instal-

lation shall be accomplished as follows:

NOTE: Index numbers refer to Figure 1-2, unless other-

wise noted.

Avoid damaging carbon-faced seal

and rotating seal seat. Mishandling

will shorten seal life. Do not touch

sealing surfaces. Surfaces can be

blemished by perspiration. Ensure

that carbon is not chipped or cracked.

1. Clean jackshaft; polish minor scratches with crocus cloth,

wipe clean and coat shaft with clean refrigerant oil. Ensure

that keyway edges are free burrs.

2. Before installing rotating seal seat, coat seat surface with

clean refrigerant oil.

3. With shiny side of seal seat facing out, coat seat with

refrigerant oil and slide over jackshaft. Do not damage o-ring.

(Photo 4-24, page 6)

CAUTION

Property of American Airlines