PAEC3200C

15

EN

General Instructions

Read these instructions carefully prior to

installation and use. Keep this manual for

future reference.

The product may only be used as set out in

the assembly and operating instructions. The

guarantee is only valid should the product be used

in the manner intended and in accordance with

the instructions.

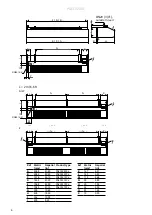

Mounting

The air curtain unit is installed horizontally with

the supply air grille facing downwards as close

to the door as possible. Minimum distance from

outlet to floor for electrically heated units is

1800 mm/70.9 in. For other minimum distances,

see fig. 4.

Brackets and torx bit are enclosed in the

gable end packaging upon delivery.

Installation and operating instructions

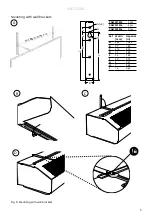

Mounting with wall brackets (fig. 6)

1.

Mount the brackets on the wall, see fig.6A

and dimension drawing fig.1. If the wall is

uneven the brackets must be compensated

for this.

2.

Hook on the unit at the lower edge of the

brackets. (Fig.6B)

3. Bend the top of the console over the the unit

and slide the units screws along the rail into

the slots on the consoles. (Fig.6C) When the

bracket is bent once, it must be replaced if

bent back more than 45 °.

4.

Lock the nuts against the brackets. (Fig.6D)

Horizontal mounting on the ceiling

Threaded rods, hanging brackets and ceiling

mounting brackets for ceiling mounting are

available as accessories, see accessories pages

and separate manuals.

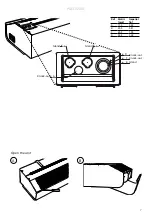

Electrical installation

The installation, which should be preceded by

an isolator switch with a contact separation of

at least 3 mm/0.12 in, should only be wired by

a competent electrician and in accordance with

the latest edition of IEE wiring regulations. The

control system is pre-installed in the air curtain.

Unit without heating or with water heating

Connected via the built-in control board with

1.5 m/4.9 ft cord.

Unit with electrical heating

The electrical connection is made on the top

of the unit. See Fig.2. 208V3~/480V3~/600V3~

power supply for heat and control (*1 *2)

should be connected to a terminal block in the

primary terminal box.

*1 480V3~/ 600V3~ Control supply is

transformed via internal transformer to 230V~

and routed through 2x 10A fuses in the primary

terminal box.

*2 208V3~ Control supply is connected

internally through 2x 10A fuses in the primary

terminal box.

The largest cable diameter for the terminal

block is AWG6. The cable glands used must

meet the protection class requirements. In the

distribution board it is to be indicated that ”the

air curtains can be supplied from more than

one connection”.

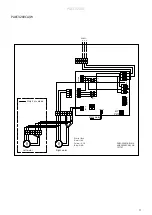

See wiring diagrams.

Operation

Air is drawn in at the top of the unit and blown

downwards shielding the door opening and

minimizing heat loss. To achieve the optimum

curtain effect the unit must extend the full

width of the door opening.

The grille for directing the outlet air is

adjustable and is normally angled outwards to

achieve the best protection against incoming

air.

The efficiency of the air curtain depends on

the air temperature, the pressure differencial

across the doorway and any wind load.

NOTE! Negative pressure in the building

considerably reduces the efficiency of the air

curtain. The ventilation should therefore be

balanced.

Application

PAEC3200C is a compact air curtain with a

recommended installation height of up to

3.2 metres/10.5 feet. The air curtain has an

integrated control system and can be remotely

controlled.

The air curtain is available without heat, with

electrical heating and with water heating.

Protection class for units with electrical heating:

IP20.

Protection class for units without heating and

units with water heating: IP21.